Microencapsulated water-based fire retardant coating and preparation method thereof

A technology of microencapsulation and fireproof coating, applied in fireproof coating, anti-corrosion coating, polyurea/polyurethane coating, etc., can solve the problems of poor fireproof performance and poor durability, reduce hygroscopicity and water solubility, increase Durability, the effect of eliminating the chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

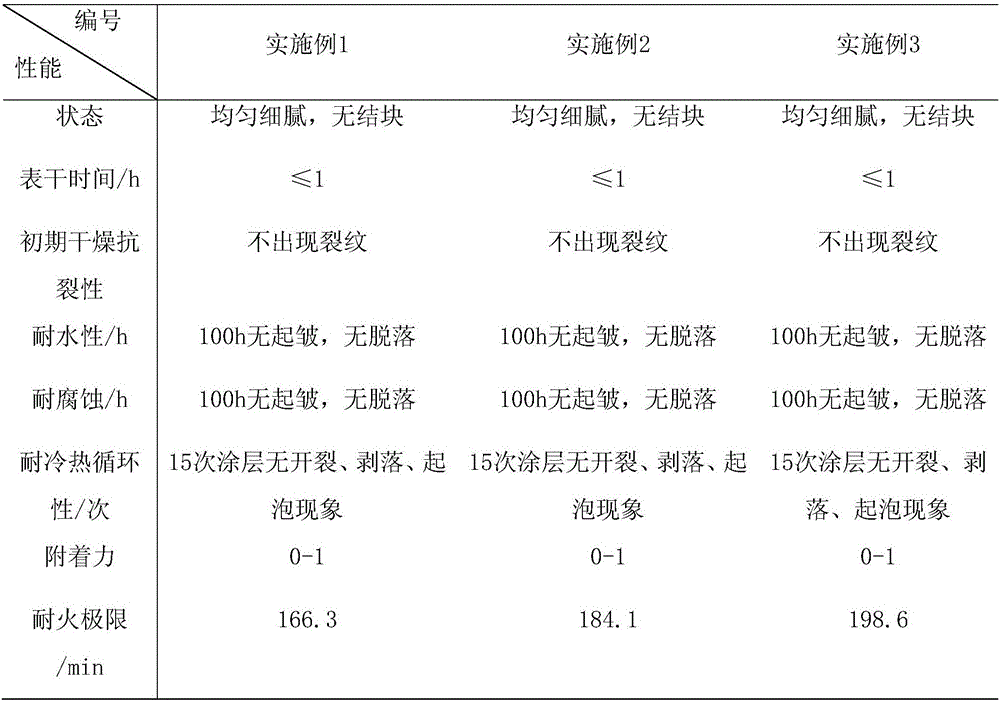

Examples

Embodiment 1

[0029]A microencapsulated water-based fireproof coating, each component and its mass percentage are: 25g of epoxy-modified water-based polyurethane emulsion, 40g of melamine formaldehyde resin microencapsulated ammonium polyphosphate, 20g of polyurethane microencapsulated calcium carbonate, hydroxyl Ethyl cellulose 1g, dispersant 1g, defoamer 1g, antifungal agent 2g, n-octanol 1g, deionized water 9g, the microencapsulated water-based fireproof coating is formed by stirring and dispersing the components uniformly.

[0030] The preparation method of the above-mentioned epoxy-modified water-based polyurethane emulsion is as follows: add 30g of polyethylene glycol (molecular weight is 1000) to the 500mL flask equipped with stirrer, thermometer stirring paddle, heat to 110 ℃, dehydration under vacuum and decompression for 1h; Then cool down to 30°C, under the protection of dry nitrogen, add 8.352g of toluene-2,4-diisocyanate, dropwise add 0.19g of dibutyltin dilaurate, raise the tem...

Embodiment 2

[0034] A microencapsulated water-based fireproof coating, each component and its mass percentage are: 30g of epoxy-modified water-based polyurethane emulsion, 35g of melamine-formaldehyde resin microencapsulated ammonium polyphosphate, 20g of polyurethane microencapsulated calcium carbonate, hydroxyl Ethyl cellulose 0.5g, dispersant 0.5g, defoamer 0.5g, antifungal agent 1g, n-octanol 0.5g, deionized water 12g, the microencapsulated water-based fireproof coating is uniformly dispersed by stirring made.

[0035] The preparation method of the above-mentioned epoxy-modified water-based polyurethane emulsion is as follows: add 30 g of polyethylene glycol (molecular weight is 1000) to a 500 mL flask equipped with a stirrer and a thermometer stirring paddle, heat to 120 ° C, and dehydrate under vacuum for 2 h; Then cool down to 35°C, under the protection of dry nitrogen, add 10.44g of toluene-2,4-diisocyanate, dropwise add 0.12g of dibutyltin dilaurate, raise the temperature to 70°C,...

Embodiment 3

[0039] A microencapsulated water-based fireproof coating, the components and their mass percentages are: 35g of epoxy-modified water-based polyurethane emulsion, 30g of melamine-formaldehyde resin microencapsulated ammonium polyphosphate, 15g of polyurethane microencapsulated calcium carbonate, hydroxyl Ethyl cellulose 1g%, dispersant 1g, defoamer 1g, antifungal agent 2g, n-octanol 1g, deionized water 14g, the microencapsulated water-based fireproof coating is formed by stirring and dispersing the components uniformly.

[0040] The preparation method of the above-mentioned epoxy-modified water-based polyurethane emulsion is as follows: add 30g of polyethylene glycol (molecular weight is 1000) to the 500mL flask equipped with stirrer, thermometer stirring paddle, heat to 120 ℃, dehydration under vacuum and decompression for 1h; Then cool down to 40°C, under the protection of dry nitrogen, add 13.572g of toluene-2,4-diisocyanate, dropwise add 0.16g of dibutyltin dilaurate, raise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com