Method of industrial production for trehalose by way of microbial fermentation

A microbial fermentation method and trehalose technology, applied in the field of starch sugar production, can solve the problems of unsuitable industrial production, high production cost, high cost, etc., and achieve the effects of low production cost, increased yield, and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

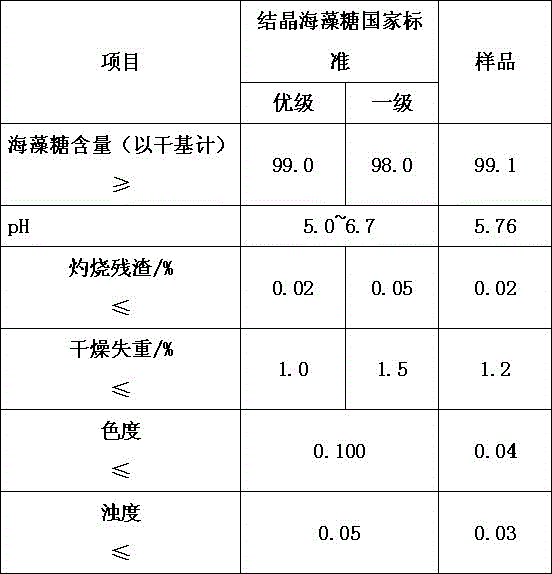

Embodiment 1

[0024] Weigh 1200kg of corn starch, add water to stir and adjust the pH value to 5.68, the concentration of the starch slurry is 14Be, the temperature of the first injection is 106°C, keep it warm for 40 minutes, check that the iodine color reaction is qualified, and the temperature of the second injection is 135°C; the liquefied liquid is 4.06M³, the concentration is 23.6 Bx, liquefied DE value 9.83%; cool down to 46°C, add pullulanase 800ml, add trehalose generating enzyme Y enzyme 28kg (enzyme fermentation broth), trehalose hydrolase Z enzyme 8kg (enzyme fermentation broth), and catalyze the reaction for 30 hours Raise the temperature to 61°C, adjust the pH to 4.4 with hydrochloric acid, add 400ml of glucoamylase, and conduct the saccharification reaction for 24 hours. 1365us / cm, volume 3.97M³ decolorized clear liquid; through cation and anion exchange, the conductivity is reduced to 21us / cm, pH5.8; concentrated to a concentration of 72.2%, volume 1.03M³, trehalose content 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com