Fe/c composite porous structure material prepared from oolitic hematite and preparation method thereof

A technology of oolitic hematite and porous structure, which is applied in the field of oolitic hematite and biomass resource utilization, can solve the problems of complex composition, carbon deposition in boilers, and low calorific value of liquid fuels, and achieve high reactivity, Effects of removing tar and improving particle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment prepares Fe / C composite porous structure material according to the following steps:

[0027] (1) Select an oolitic hematite ore sample with an iron grade of 51.4%, crush it and pass through a 0.15mm sieve to obtain oolitic hematite powder; crush rapeseed straw and pass through a 1mm sieve to obtain straw powder;

[0028] (2) Weigh the oolitic hematite powder and straw powder according to the mass ratio of 1:2; first, spray a little water on the straw powder to make it moist, then add the oolitic hematite powder and mix evenly, bake dry to obtain a mixture;

[0029] (3) above-mentioned compound is added in the hopper of screw extruder molding machine, extruded and formed into the rod-shaped particle of diameter 6mm;

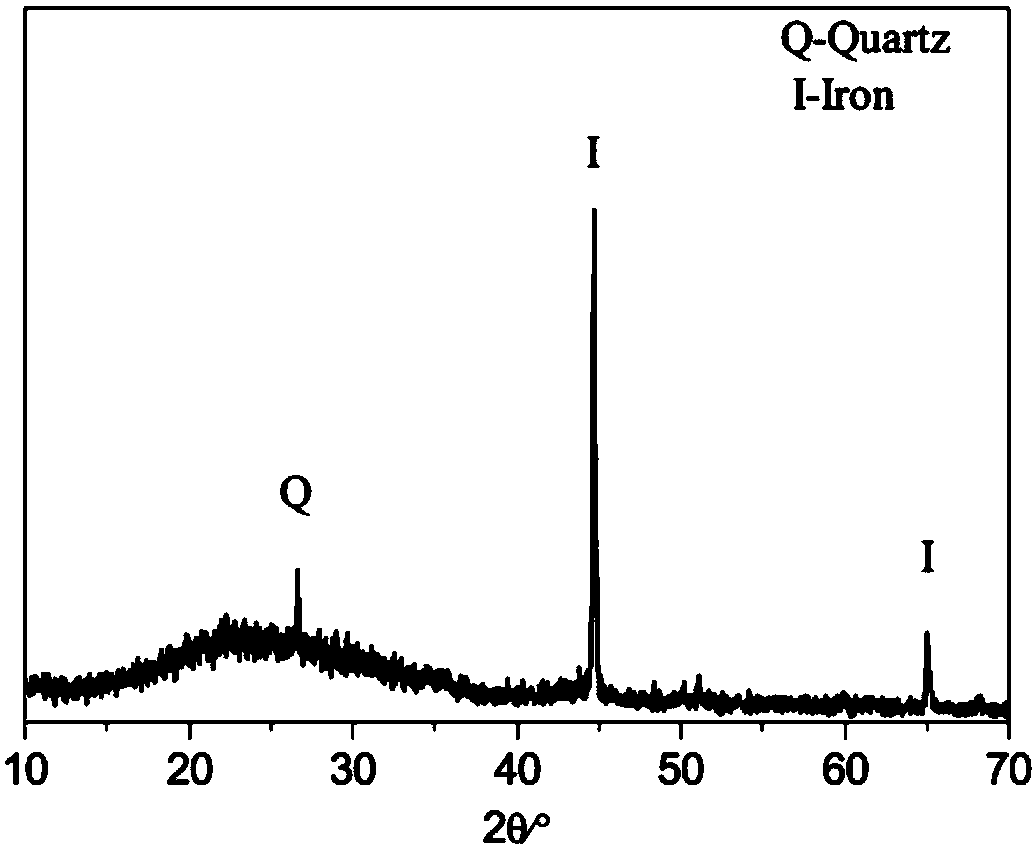

[0030] (4) Roast the formed rod-shaped particles in a tube furnace at 850°C for 25 minutes in a hydrogen atmosphere, and then naturally cool to room temperature in an oxygen-free atmosphere to obtain Fe / C composite porous structure materi...

Embodiment 2

[0034] This embodiment prepares Fe / C composite porous structure material according to the following steps:

[0035] (1) Select an oolitic hematite ore sample with an iron grade of 45.7%, crush it, and pass it through a 0.15mm sieve to obtain oolitic hematite powder; crush rape straw and pass it through a 1mm sieve to obtain straw powder;

[0036] (2) Weigh the oolitic hematite powder and straw powder according to the mass ratio of 1:5; first, spray a little water on the straw powder to make it moist, then add the oolitic hematite powder and mix evenly, bake dry to obtain a mixture;

[0037] (3) above-mentioned compound is added in the hopper of screw extruder molding machine, extruded and formed into the rod-shaped particle of diameter 6mm;

[0038] (4) Roast the formed rod-shaped particles in a tube furnace at 750°C for 30 minutes in a hydrogen atmosphere, and then naturally cool to room temperature in an oxygen-free atmosphere to obtain Fe / C composite porous structure mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com