Method for leaching tellurium in tellurium slag in co-oxidation mode

A technology for synergistic oxidation and leaching of slag, applied in the field of hydrometallurgy to realize synergistic leaching of tellurium slag and effective separation and enrichment of valuable metals, it can solve the problems of increasing the difficulty of separation and recovery of tellurium, poor effect, etc., and achieve easy industrial production and application , The effect of simple reaction conditions and large reduction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

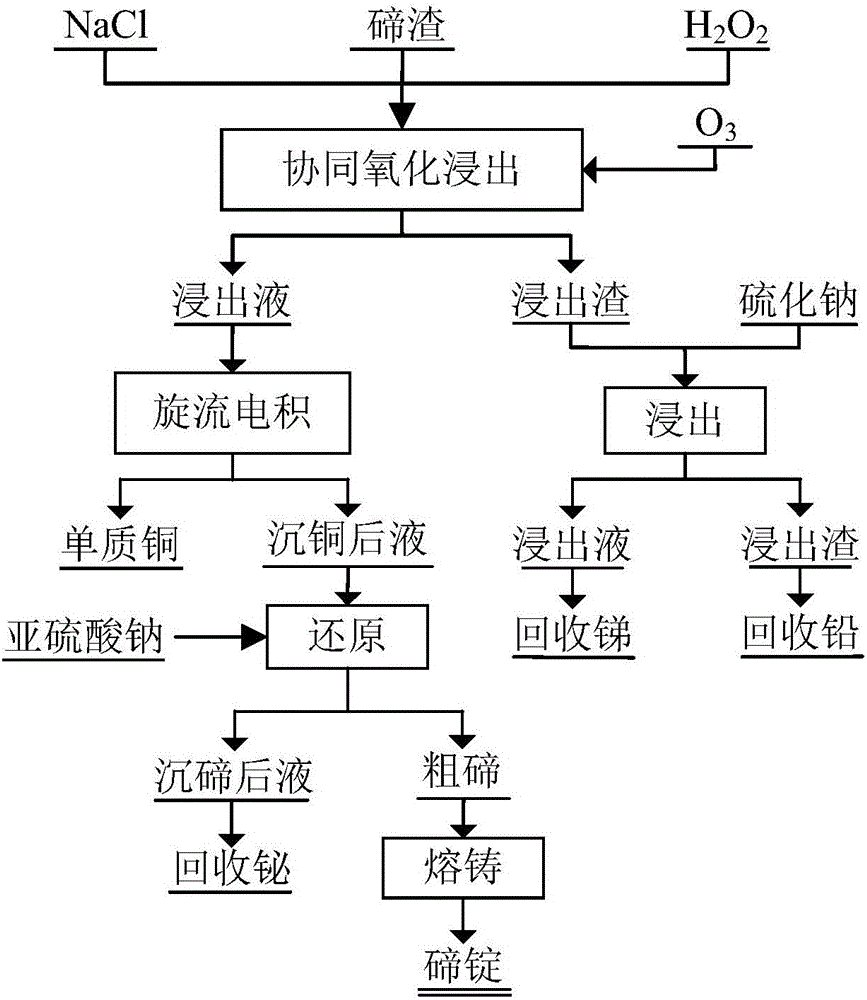

[0033] A method for synergistic oxidation leaching of tellurium in tellurium slag of the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

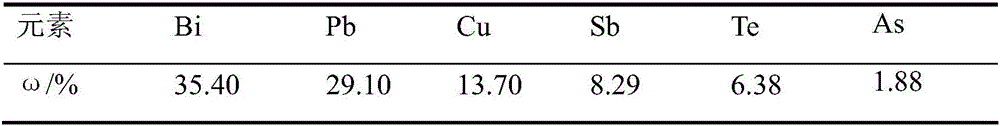

[0034] (1) prepare the sulfuric acid solution of 4.60mol / L, and add the sodium chloride of tellurium slag weight ratio 20%, be heated to 90 ℃, pass into ozone according to the flow rate of 1L / min, then according to liquid-solid ratio (solution volume L and The solid mass (Kg ratio) is 6:1, and the tellurium slag that is ground to 100% through a sieve with a pore size of 150 microns is added, and stirred and leached;

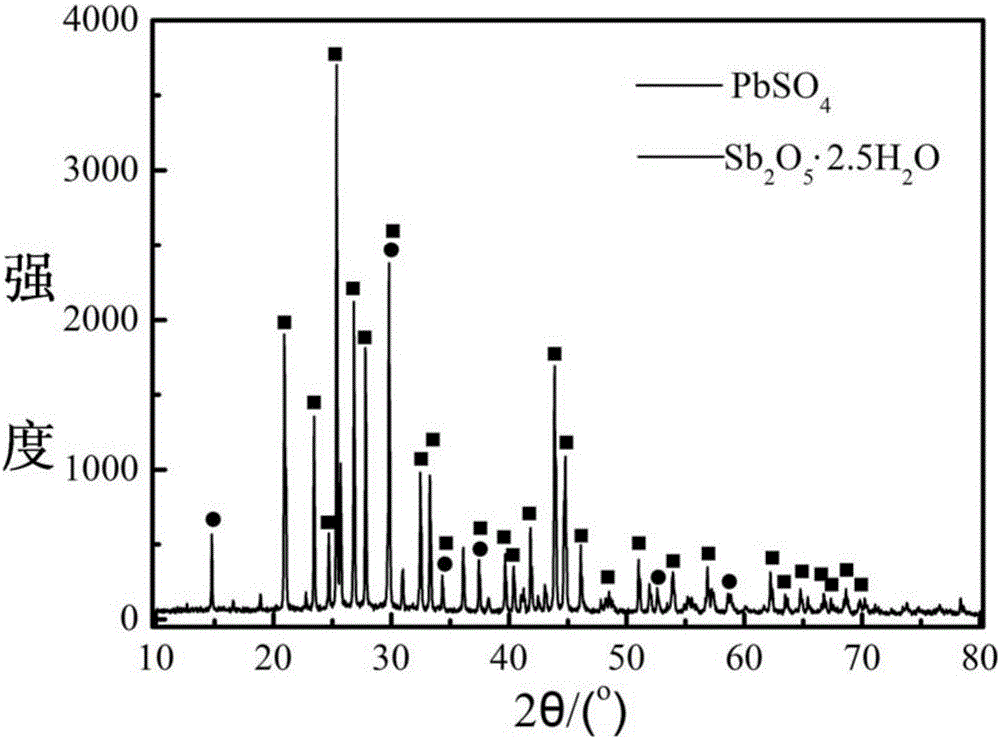

[0035] (2) Keep the stirring speed at 300r / min, and add the sulfuric acid volume 20% concentration by controlling the speed of constant flow pump 10r / min to carry out the synergistic oxidation reaction of 30% hydrogen peroxide, react for 5h, and use vacuum filtration after the reaction Realize liquid-solid separation, obtain leaching slag containing antimony and lead (see...

Embodiment 2

[0038] A method for synergistic oxidation leaching of tellurium in tellurium slag of the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

[0039] (1) prepare the sulfuric acid solution of 3.68mol / L, and add the sodium chloride of tellurium slag weight ratio 25%, be heated to 85 ℃, pass into ozone according to 2L / min, then according to liquid-solid ratio (solution volume L and solid mass) Kg ratio) 7:1 is added to tellurium slag that is ground to 100% through a sieve with an aperture of 100 microns, stirred and leached;

[0040] (2) Keep stirring speed 300r / min, and add sulfuric acid volume 25% concentration by controlling the speed of constant flow pump 20r / min to be the carrying out of 30% hydrogen peroxide synergistic oxidation reaction, reaction time 7h, adopt vacuum filtration mode to realize after reaction The liquid and solid are separated to obtain leaching slag containing antimony and lead and leaching solution co...

Embodiment 3

[0043] A method for synergistic oxidation leaching of tellurium in tellurium slag of the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

[0044] (1) prepare the sulfuric acid solution of 2.76mol / L, and add the sodium chloride of tellurium slag weight ratio 30%, be heated to 80 ℃, pass into ozone according to the flow rate of 2L / min, press liquid-solid ratio (solution volume L and solid mass Kg ratio) 8:1, add tellurium slag that is ground to 100% and pass through a sieve with a pore size of 75 microns, and stir for leaching;

[0045] (2) Keep the stirring speed at 300r / min, and add 30% concentration of sulfuric acid volume by controlling the speed of constant flow pump 15r / min to carry out the coordinated oxidation reaction of hydrogen peroxide with a concentration of 30%. The reaction time is 8h, and the vacuum filtration method is adopted after the reaction Liquid-solid separation is realized to obtain leaching slag co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com