Eosin Y based electrochemiluminescence sensor

An electrochemistry and sensor technology, applied in the direction of chemiluminescence/bioluminescence, electrochemical variables of materials, analysis by making materials undergo chemical reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Polishing of glassy carbon electrode: The glassy carbon electrode is first mechanically ground and polished on the chamois covered with alumina powder, washed with secondary water to remove the residual powder on the surface, and then moved into an ultrasonic water bath for cleaning, 2 minutes each time, repeated three times , until cleaned, and finally washed thoroughly with ethanol, dilute acid and water in sequence;

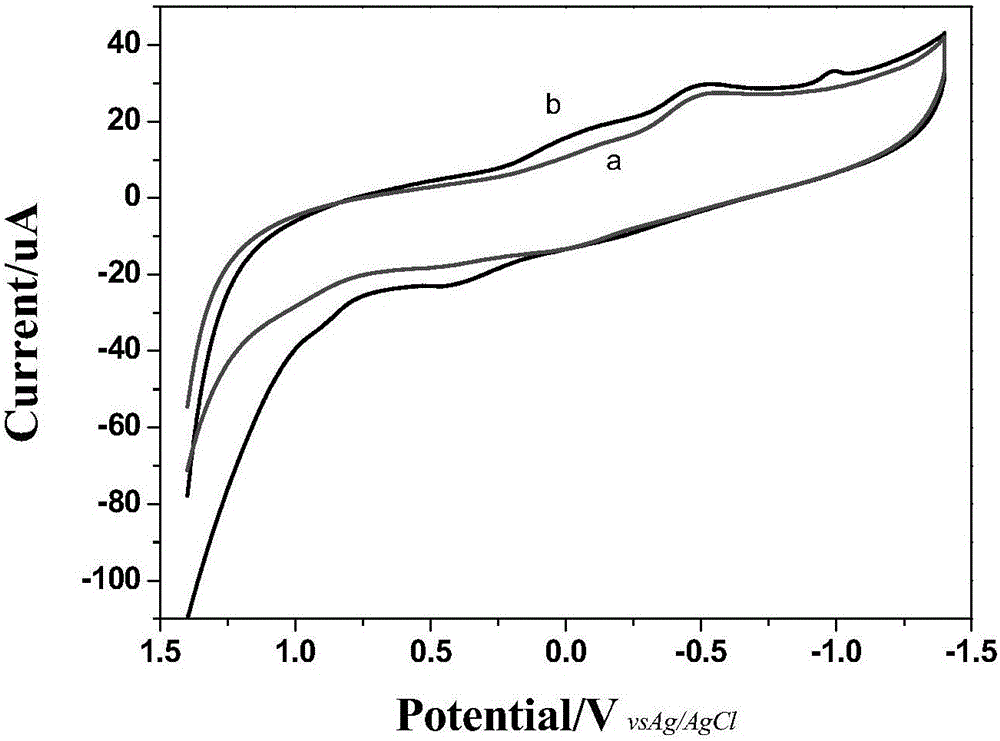

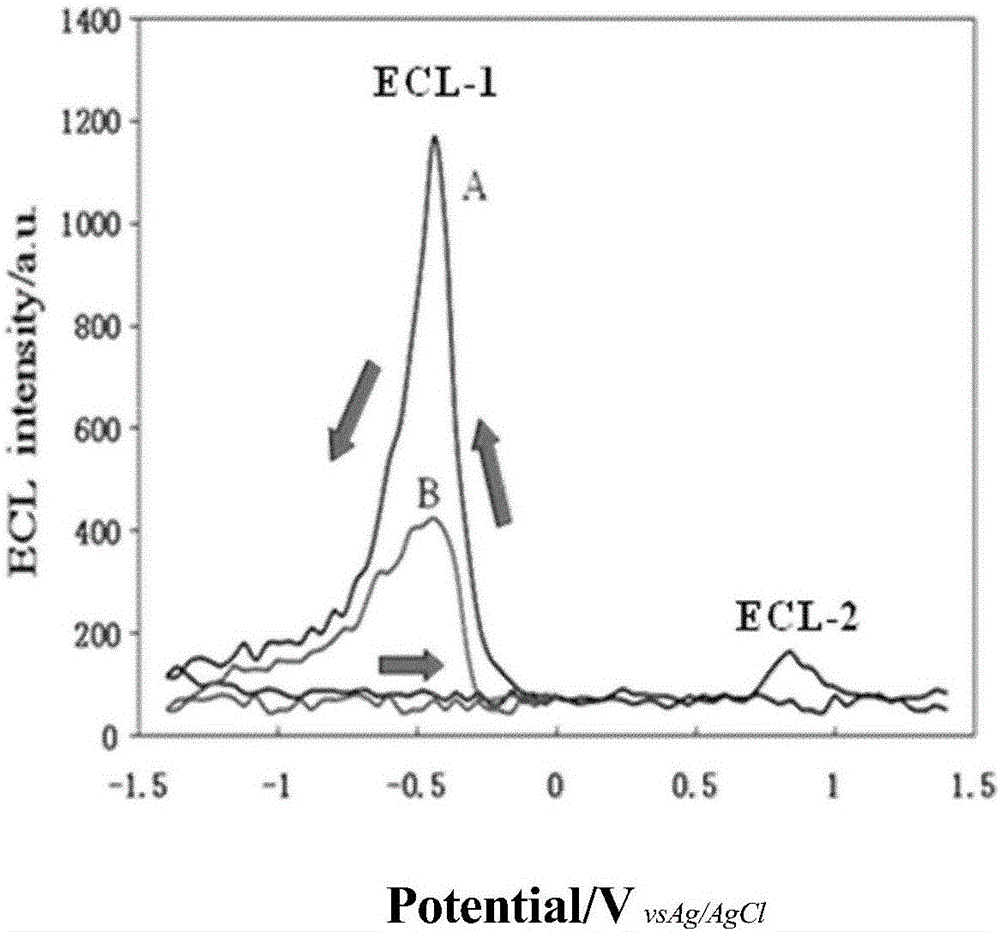

[0040](2) The three-electrode system was used for the test, with the bare glassy carbon electrode as the working electrode, the platinum wire electrode as the counter electrode, and the Ag / AgCl as the reference electrode. voltage to obtain the cyclic voltammetry curve of the bare glassy carbon electrode in pH 10.0 phosphate buffer solution without eosin Y (e.g. figure 1 shown in a); the above three-electrode insert containing 1 × 10 -4 The pH 10.0 phosphate buffer solution of mol / L eosin Y was applied, and the cyclic voltammetry voltage was appli...

Embodiment 2

[0042] (1) Polishing of glassy carbon electrode: The glassy carbon electrode is first mechanically ground and polished on the chamois covered with alumina powder, washed with secondary water to remove the residual powder on the surface, and then moved into an ultrasonic water bath for cleaning, 2 minutes each time, repeated three times , until cleaned, and finally washed thoroughly with ethanol, dilute acid and water in sequence;

[0043] (2) Preparation of oxidized glassy carbon electrode: The clean glassy carbon electrode was moved into a 0.1 mol / L sulfuric acid solution, and the surface of the glassy carbon electrode was electrochemically pretreated to obtain an oxidized glassy carbon electrode. The oxidized glassy carbon electrode was rinsed with secondary water and stored in pH 7.0 phosphate buffer solution for use;

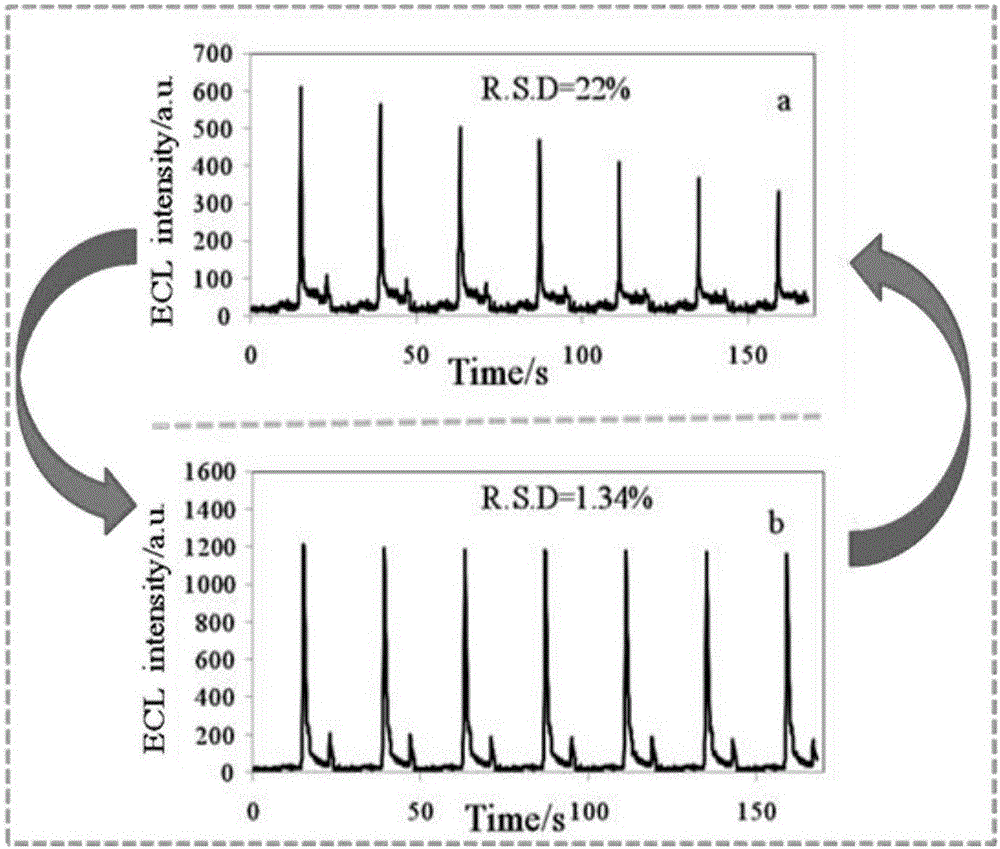

[0044] (3) The three-electrode system was used for the test. The oxidized glassy carbon electrode was used as the working electrode, the platinum wire elect...

Embodiment 3

[0046] (1) Polishing of glassy carbon electrode: The glassy carbon electrode is first mechanically ground and polished on the chamois covered with alumina powder, washed with secondary water to remove the residual powder on the surface, and then moved into an ultrasonic water bath for cleaning, 2 minutes each time, repeated three times , until cleaned, and finally washed thoroughly with ethanol, dilute acid and water in sequence;

[0047] (2) Preparation of oxidized glassy carbon electrode: The clean glassy carbon electrode was moved into a 0.1 mol / L sulfuric acid solution, and the surface of the glassy carbon electrode was electrochemically pretreated to obtain an oxidized glassy carbon electrode. The oxidized glassy carbon electrode was rinsed with secondary water and stored in pH 7.0 phosphate buffer solution for use;

[0048] (3) The three-electrode system was used for the test. The bare glassy carbon electrode was used as the working electrode, the platinum wire electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com