Coke oven flue gas desulfurization technology and system

A desulfurization process and desulfurization system technology, applied in gas treatment, membrane technology, and dispersed particle separation, etc., can solve the problems of not really realizing SO2 emission reduction, failing to meet the desulfurization requirements of coke oven flue gas, and low flue gas outlet temperature , achieve the effect of short flue gas residence time, improved desulfurization effect, and small spraying amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

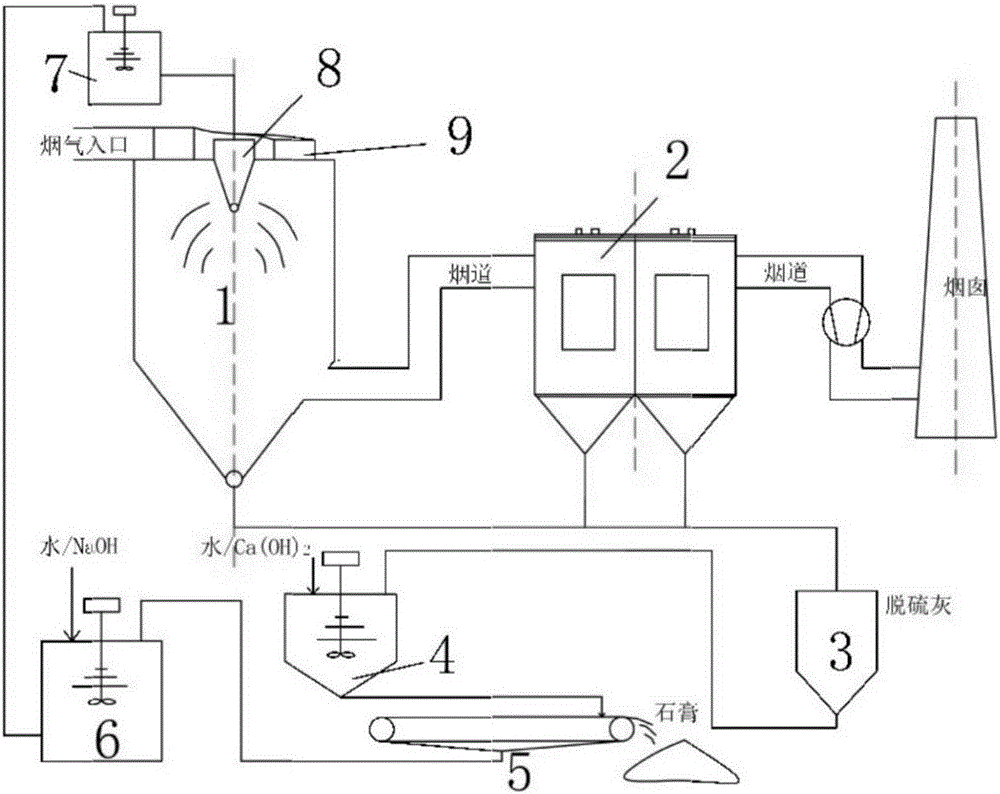

[0032] The coke oven flue gas desulfurization system in this embodiment includes a spray drying tower 1, a bag filter 2, a desulfurization dust buffer 3, a sodium-alkali regeneration tank 4, a vacuum belt dehydrator 5, a sodium-alkali mixing tank 6, and a slurry buffer tank 7.

[0033]The spray drying tower 1 and the bag filter 2 are connected by a flue. The spray drying tower 1 includes a spray drying tower body, a rotary sprayer 8 is arranged on the tower body, and a hopper is arranged at the lower end of the tower body. The bag filter 2 includes a flue gas dust removal part connected up and down and an ash bin for collecting the dust removed by the dust removal part. The ash bin of the bag filter 2 and the hopper of the spray drying tower 1 pass through the pneumatic ash conveying pipeline and the desulfurization dust buffer bin 3 respectively. connect. The desulfurization dust buffer bin 3 and the sodium-alkali regeneration tank 4 are connected by a pneumatic ash conveying...

Embodiment 2

[0039] The coke oven flue gas desulfurization process in this embodiment is realized by using the coke oven flue gas desulfurization system in Example 1.

[0040] The temperature is 180℃, SO 2 Concentration is 300mg / Nm 3 The coke oven flue gas from the flue gas enters the spray drying tower 1 from the flue gas distributor 9, and is in co-current contact with the droplets of the caustic soda solution sprayed by the rotary atomizer 8. The concentration of the caustic soda solution sprayed into the tower is 20wt%, the design value of the Na2 / S molar ratio is 1.05, the design value of the residence time of the flue gas in the tower is 5s, the average flow rate of the interface in the tower is 0.3m / s, the caustic soda solution The control range of the average particle size of the mist droplets is 60-80 μm. Most of the sodium hydroxide reacts with sulfur dioxide in the tower to form sodium sulfite and is dried into solid desulfurized ash. The desulfurized ash enters the bag filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com