A composite oxide catalyst for synthesizing salicylamide from urea and phenol, its preparation method and application

A composite oxide, salicylamide technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, carboxylic acid amide preparation, etc., can solve the problem of low salicylamide yield and stable catalyst structure problems such as poor performance, to achieve the effect of being conducive to industrialization, easy to operate, and widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

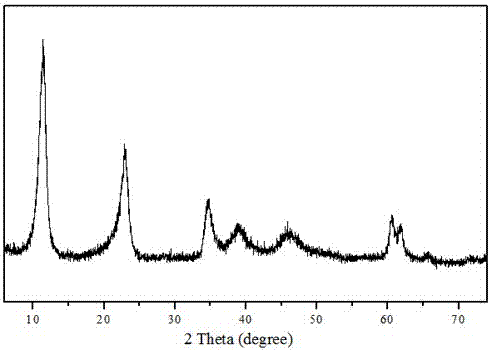

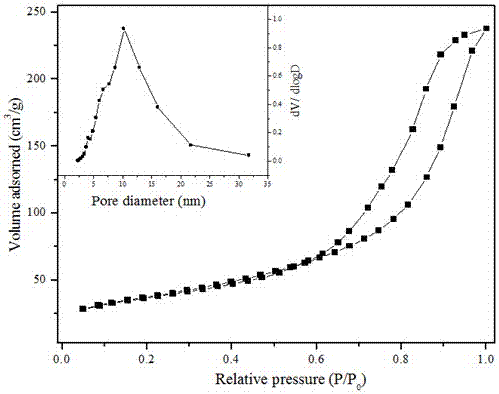

preparation example Construction

[0031] The present invention also provides the preparation method of described catalyst, comprises the following steps:

[0032] In the first step, the nitrate of magnesium nitrate, aluminum nitrate and metal M is pressed by catalyst metal Mg x Al y m z o m The molar composition was dissolved in deionized water at the same time to form a 100 mL solution with a catalyst concentration of 0.2-1.0 mol / L; at the same time, NaOH and Na 2 CO 3 Dissolved in 100 mL of deionized water as a precipitant to prepare a precipitant, in which NaOH and Na 2 CO 3 The amount of the substance is respectively 2 times and 1 / 5 of the sum of the amount of metal nitrate substances;

[0033] In the second step, control the temperature in a water bath at 40-60 o C. Drop the above-mentioned mixed nitrate solution and precipitant into 100 mL deionized water at the same time, stir vigorously, and keep the pH value of the solution at 8-12 at the same time, and the dropwise addition is completed in abo...

Embodiment 1

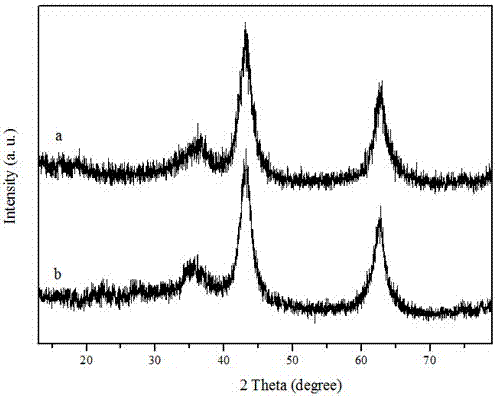

[0041] Take 0.02mol Mg(NO 3 ) 2 ·6H 2 O, 0.01mol Al(NO 3 ) 3 9H 2 O and 0.002mol Ni(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of deionized water, and the total concentration of the three metal salts was 0.32 mol / L. At the same time, NaOH and Na 2 CO 3 Dissolve in 100mL deionized water to prepare a precipitant, wherein the concentration of NaOH is 0.64 mol / L, NaOH 2 CO 3 The concentration is 0.064 mol / L, and the water bath controls the temperature at 60 o C. Under vigorous stirring, drop the above mixed salt solution and precipitant into 100 mL deionized water at the same time, keep the pH value of the solution at 9, and complete the dropwise addition in 1 h. After precipitation is complete, 80 o C hydrothermal treatment for 15 h. The mixture after decompression suction filtration water heat treatment is washed with deionized water until the filtrate is neutral, and then the filter cake is o C drying to obtain the precursor of the catalyst. Finally in N 2 Atmosp...

Embodiment 2

[0048] Take 0.03mol Mg(NO 3 ) 2 ·6H 2 O, 0.01mol Al(NO 3 ) 3 9H 2 O and 0.005mol La(NO 3 ) 3 ·6H 2 O was dissolved in 100 mL of deionized water, and the concentration of the metal salt was 0.45 mol / L. At the same time, NaOH and Na 2 CO 3 Dissolve in 100 mL deionized water to prepare the precipitant. Control the temperature in a water bath at 50 o C. Drop the above-mentioned mixed salt solution and precipitant into 100 mL deionized water at the same time, stir vigorously, and keep the pH value of the solution at 10, and the dropwise addition is completed within 1.2 h. After precipitation is complete, the colloid of gained is placed in the crystallization still, at 80 o C hydrothermal treatment for 20 h. The mixture after water heat treatment was filtered under reduced pressure, and washed repeatedly with deionized water until the filtrate was neutral. Then filter cake at 100 o C drying to obtain the precursor of the catalyst, and finally in N 2 atmosphere at 450...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com