Chitosan modified derivative corrosion inhibitor and preparation method thereof

A chitosan modification and derivative technology, which is applied in the field of metal corrosion and protection, can solve the problems of high corrosion inhibition efficiency of molybdenum-based corrosion inhibitors, insufficient concentration of anodic corrosion inhibitors, and aggravated eutrophication. Effects of water solubility and biocompatibility, corrosion inhibition, and wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

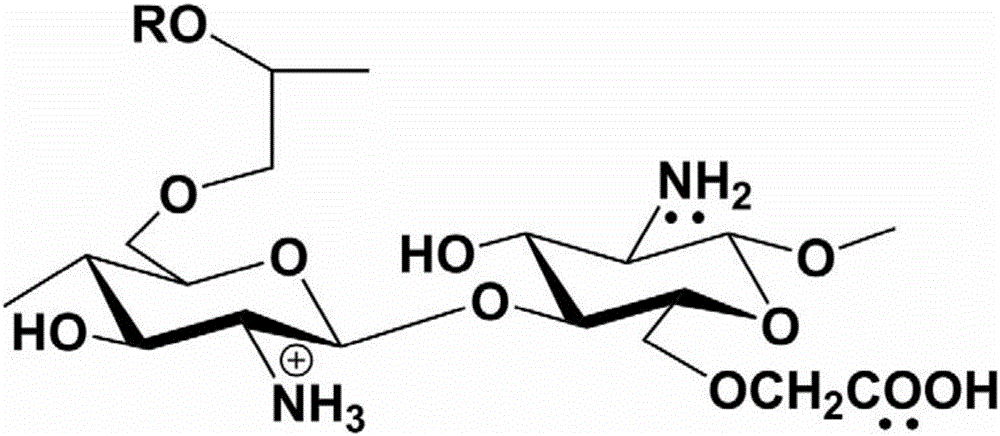

[0037] The preparation method of chitosan derivative corrosion inhibitor specifically includes the following steps:

[0038] Step 1: Preparation of hydroxypropyl chitosan.

[0039]Mix chitosan, NaOH and isopropanol, stir at room temperature for 1-2 h; then add tetramethylammonium hydroxide solution and propylene oxide, stir at room temperature for 30-40 min, and then heat up to 40-70 °C , stirring at this temperature under reflux for 8-9h, neutralizing with aqueous hydrochloric acid solution after the reaction to neutrality, then precipitating the product with acetone, suction filtration to obtain the crude product; dissolving the obtained crude product in deionized water, then adding a large amount of ethanol to precipitate the product, filter, repeat the above steps 3-5 times, and put it in an oven for drying at 50°C.

[0040] Step 2: Preparation of carboxymethylated hydroxypropyl chitosan.

[0041] Dissolve the crude product obtained above in water, stir at room temperatu...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is only in step 2, which is specifically:

[0044] Step 2: Preparation of carboxymethylated hydroxypropyl chitosan.

[0045] The above-mentioned hydroxypropyl chitosan is weighed and dissolved in distilled water, stirred at room temperature for 0.5-1 h, then added with aqueous sodium hydroxide solution, and stirred for 6-7 h for alkalization. The aqueous solution of chloroacetic acid is added dropwise, the dropwise addition is completed, the temperature is raised to 40-70° C., and the reaction is carried out for a period of time to obtain a uniform and transparent liquid. Add acetic acid to adjust to neutrality, use acetone for precipitation, and suction filtration to obtain a crude product. The obtained crude product is dissolved in deionized water, and then a large amount of ethanol is added to it to precipitate the product, and suction filtration is carried out with a suction filtration bottle. Repeat the above...

Embodiment 3

[0049] The difference between this embodiment and Embodiment 2 is only in step 2, which is specifically:

[0050] Step 2: Preparation of carboxymethylated hydroxypropyl chitosan.

[0051] Weigh the above-mentioned hydroxypropyl chitosan and dissolve it in distilled water, stir at room temperature for 0.5-1 h, add chloroacetic acid aqueous solution dropwise at a speed of 30-40 drops / min, after the dropwise addition is completed, heat up to 40-70 ° C, and react for a period of time, A homogeneous transparent liquid was obtained. Add acetic acid to adjust to neutrality, use acetone for precipitation, and suction filtration to obtain a crude product. The obtained crude product is dissolved in deionized water, and then a large amount of ethanol is added to it to precipitate the product, and suction filtration is carried out with a suction filtration bottle. Repeat the above steps 3-5 times and dry at 50-60°C to obtain the final product. The ratio of hydroxypropyl chitosan (g), di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com