Athletic ground runway material

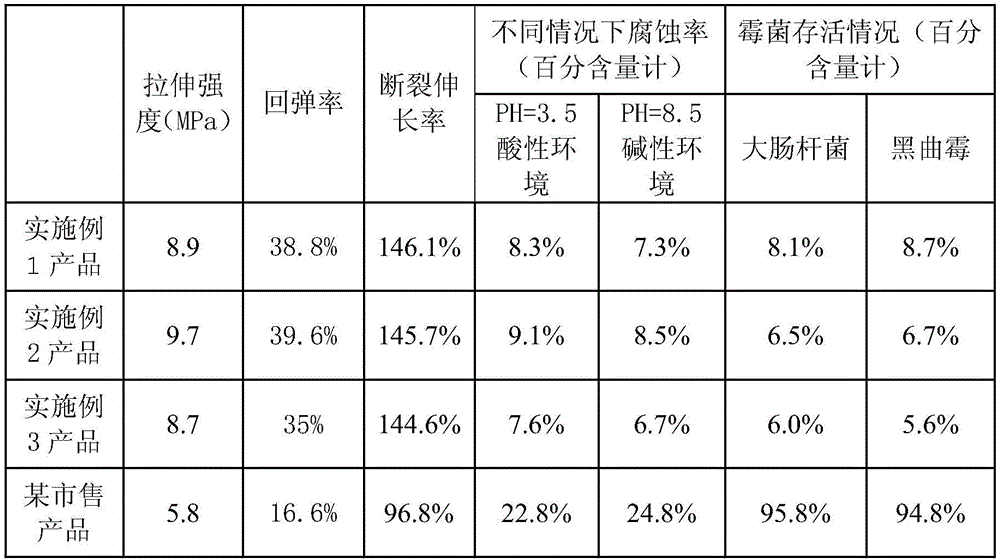

A technology for sports fields and runways, applied in the field of runway materials, can solve the problems of incompletely improving the rebound rate, tensile strength and elongation at break of plastic runways, and restrict the performance of plastic runways, so as to achieve good rebound rate and good performance. Corrosion resistance, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The sports track material in the present embodiment is composed of the following components in parts by mass: 18 parts of methyl ethyl ketone oxime, 20 parts of barium sulfate, 16 parts of silica sol, 14 parts of alkoxylated lauryl ester, 20 parts of cottonseed oil , 16 parts of squalane, 14 parts of sodium lauryl sulfate, 20 parts of chlorinated paraffin, 16 parts of titanium dioxide, 14 parts of zinc soap, 20 parts of triaryl phosphate, 16 parts of calcium oxide, 16 parts of hexabromobenzene, 14 parts of glyceryl stearate, 20 parts of oleic acid amide, 16 parts of tert-butyl hydroperoxide, 14 parts of benzoyl peroxide, 20 parts of diethyl aminomalonate, 16 parts of polytetrahydrofuran ether glycol, 14 parts of zirconium powder, 20 parts of activated calcium carbonate, 16 parts of white quartz powder, 14 parts of calcium chloride, 20 parts of polyurethane.

[0023] The calcium oxide is composed of powders with three particle sizes and meshes, the particle sizes and mes...

Embodiment 2

[0033] The sports track material in the present embodiment is composed of the following components in parts by mass: 20 parts of methyl ethyl ketone oxime, 22 parts of barium sulfate, 18 parts of silica sol, 16 parts of alkoxylated lauryl ester, 22 parts of cottonseed oil , 18 parts of squalane, 16 parts of sodium lauryl sulfate, 22 parts of chlorinated paraffin, 18 parts of titanium dioxide, 16 parts of zinc soap, 22 parts of triaryl phosphate, 18 parts of calcium oxide, 18 parts of hexabromobenzene, 16 parts of glyceryl stearate, 22 parts of oleic acid amide, 18 parts of tert-butyl hydroperoxide, 16 parts of benzoyl peroxide, 22 parts of diethyl aminomalonate, 18 parts of polytetrahydrofuran ether glycol, oxidation 16 parts of zirconium powder, 22 parts of activated calcium carbonate, 18 parts of white quartz powder, 16 parts of calcium chloride, 22 parts of polyurethane.

[0034] The calcium oxide is composed of powders with three particle sizes and meshes, the particle siz...

Embodiment 3

[0044] The sports track material in the present embodiment is composed of the following components in parts by mass: 22 parts of methyl ethyl ketone oxime, 24 parts of barium sulfate, 20 parts of silica sol, 18 parts of alkoxylated lauryl ester, 24 parts of cottonseed oil , 20 parts of squalane, 18 parts of sodium lauryl sulfate, 24 parts of chlorinated paraffin, 20 parts of titanium dioxide, 18 parts of zinc soap, 24 parts of triaryl phosphate, 20 parts of calcium oxide, 20 parts of hexabromobenzene, 18 parts of glyceryl stearate, 24 parts of oleic acid amide, 20 parts of tert-butyl hydroperoxide, 18 parts of benzoyl peroxide, 24 parts of diethyl aminomalonate, 20 parts of polytetrahydrofuran ether glycol, 18 parts of zirconium powder, 24 parts of activated calcium carbonate, 20 parts of white quartz powder, 18 parts of calcium chloride, 24 parts of polyurethane.

[0045] The calcium oxide is composed of powders with three particle sizes and meshes, the particle sizes and mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com