Sesame oil extraction method

An extraction method, sesame oil technology, applied in the direction of fat oil/fat production, fat generation, etc., can solve the problems of sesame protein destruction, spoilage, long process, etc., achieve the effect of promoting oil release, mild extraction conditions, and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

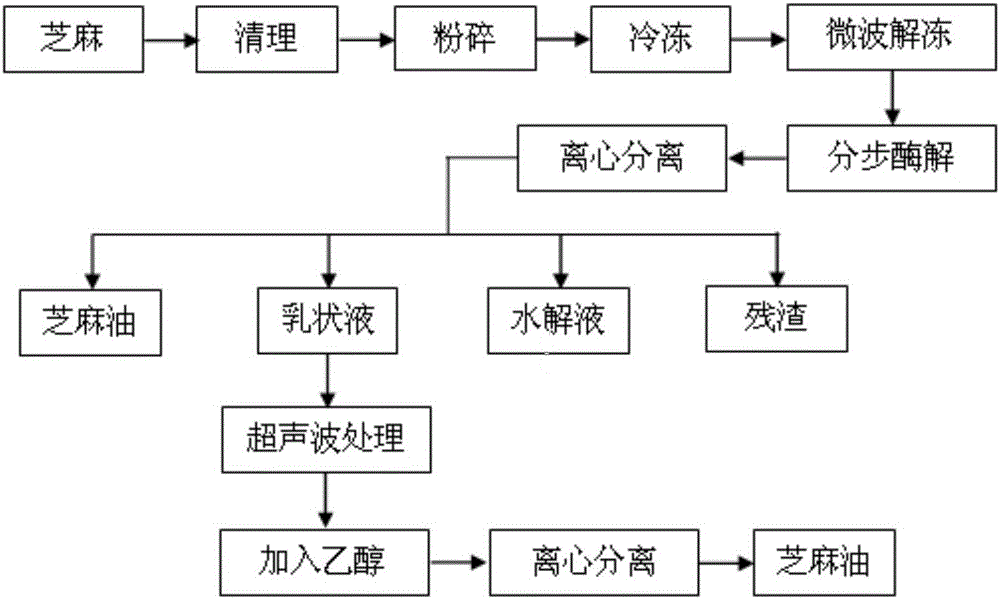

[0046] A method for extracting sesame oil, comprising the following steps:

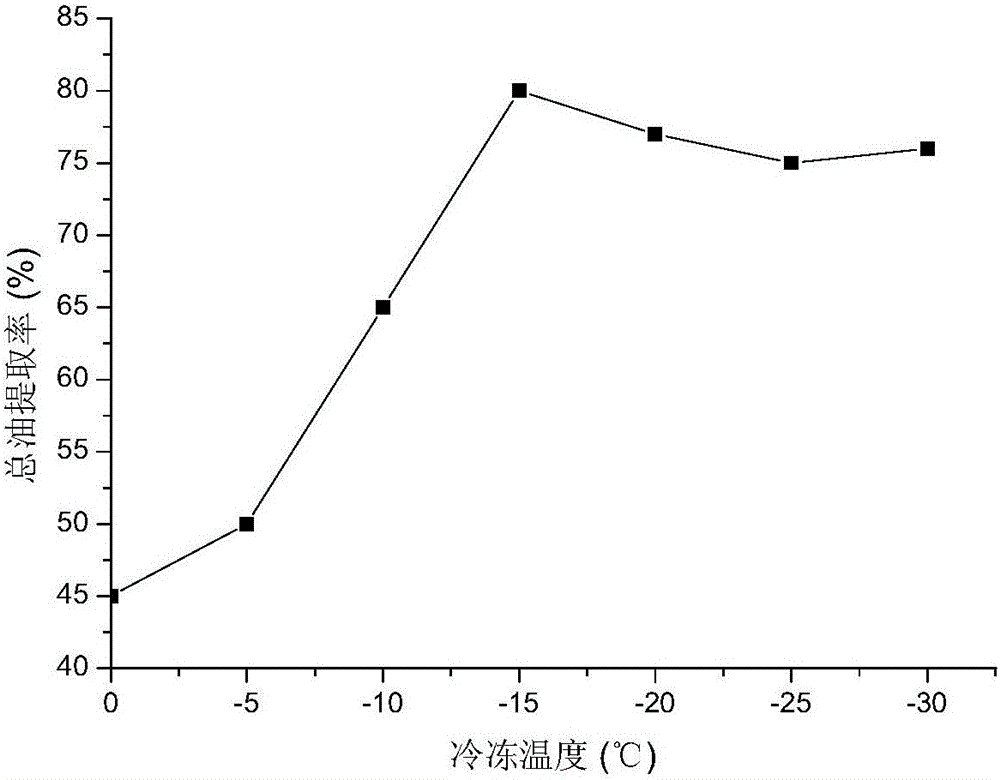

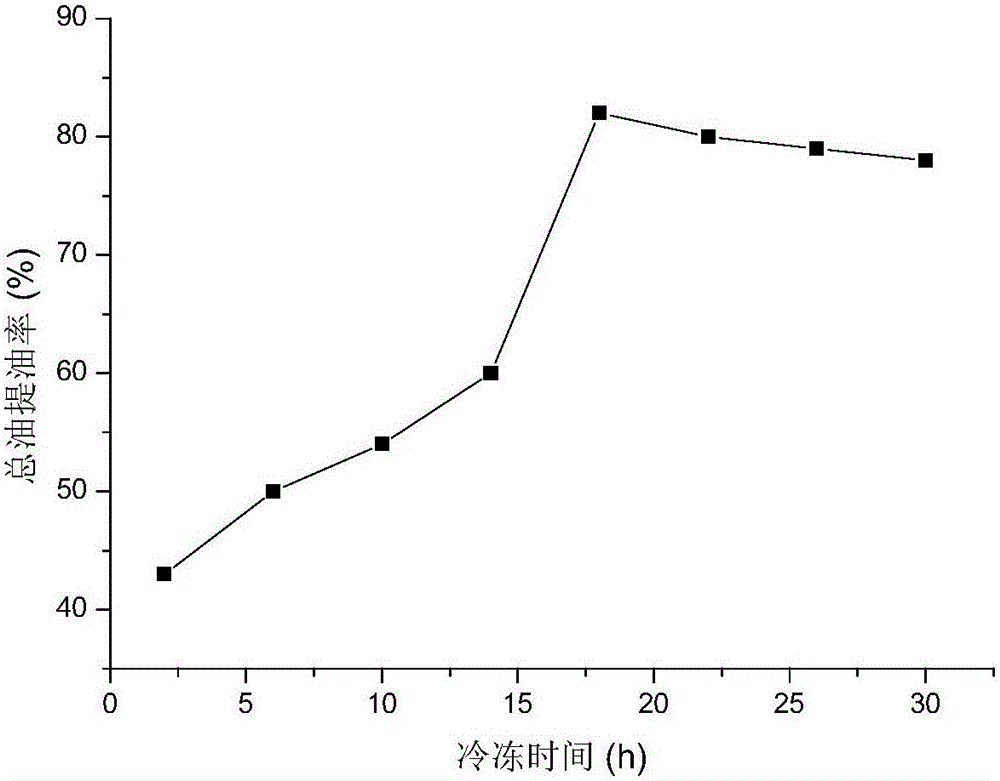

[0047] (1) Sesame powder is obtained after cleaning, peeling and pulverizing the sesame seeds, according to the ratio of sesame powder: water mass ratio of 1:1, water is added to the sesame powder for moisture adjustment, and freezing treatment is carried out after the moisture adjustment, described freezing treatment Carry out under the following process parameters: freezing temperature is 0~-30℃; freezing time is 2~30h;

[0048] (2) The frozen sesame powder is thawed by microwave, and the microwave thawing process is carried out under the following process parameters: the microwave thawing temperature is 30-100°C, the microwave thawing power is 450-800W, and the microwave thawing time is 2-16min ;

[0049] (3) The sesame powder after thawing is carried out step by step enzymolysis, and described step by step enzymolysis is carried out under the following process parameter: first adopt compound cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com