Method of processing lignocellulosic material using an alkaline delignification agent

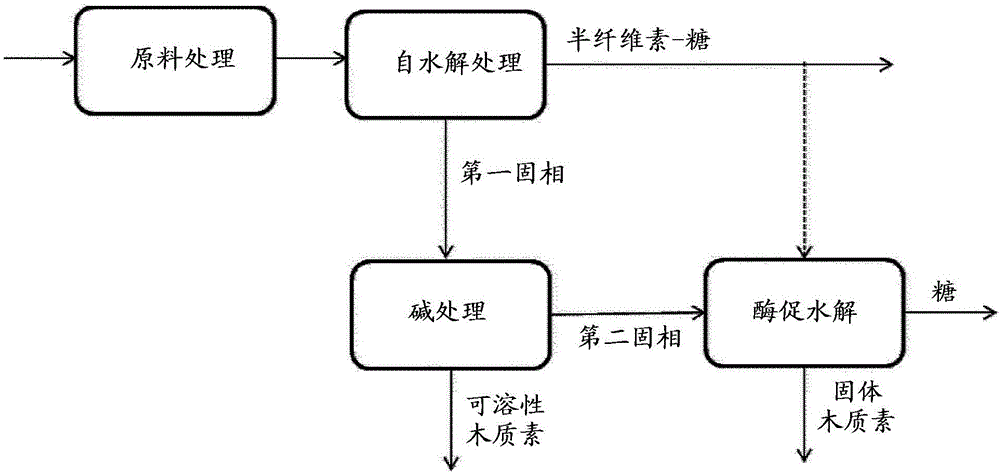

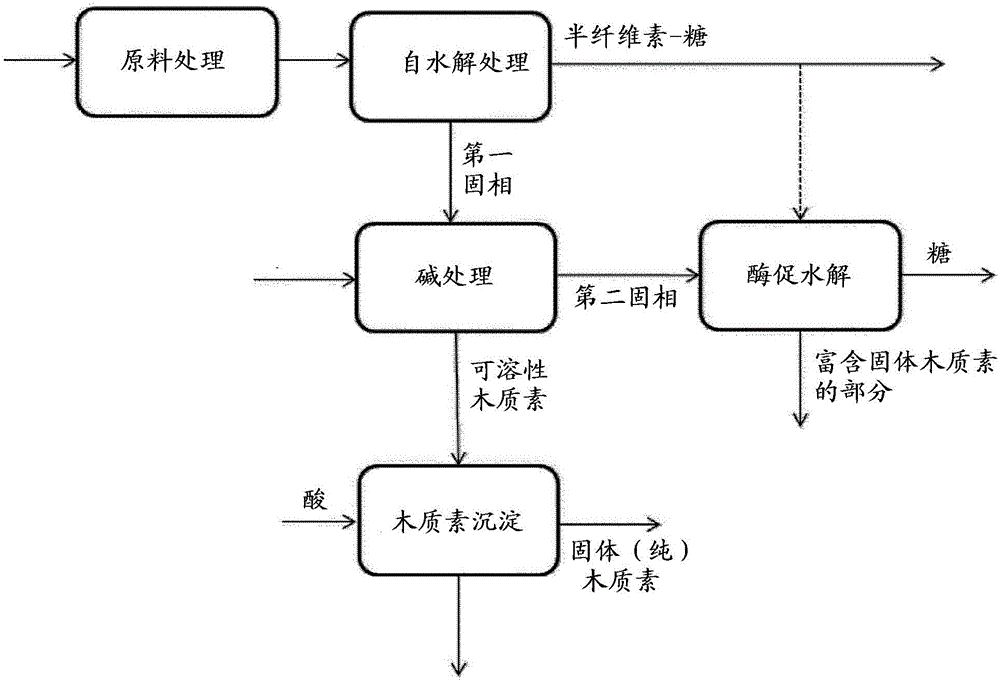

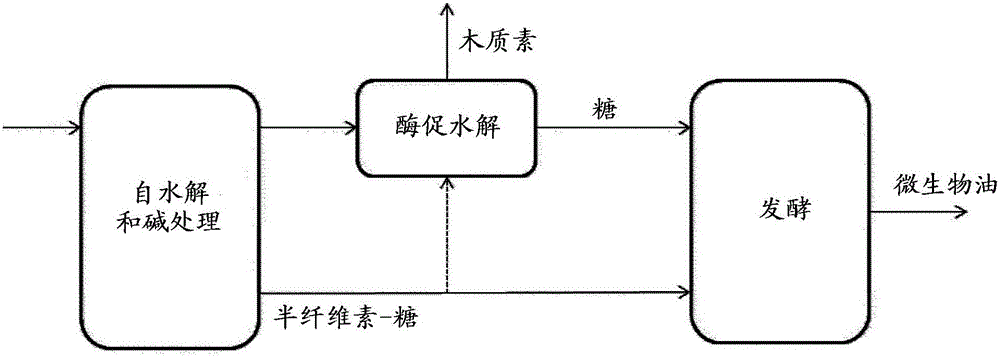

一种木质纤维素、木质化的技术,应用在生物燃料、发酵等方向,能够解决没有显著地改善纤维素转化、无法用于生产单细胞油等问题,达到高总糖产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0268] Autohydrolysis of wheat straw (with pre-adjusted pH)

[0269] A suspension is prepared by mixing 20 g of wheat straw pre-ground to pass through a 1 mm sieve and 180 g of water. The suspension was adjusted to pH 4.5 with acetic acid. The suspension was transferred to a high pressure reactor and then heated isothermally to a temperature of 170°C-200°C using a heating mantle with continuous stirring. Temperature data were recorded during heating and used to calculate autohydrolysis severity (Equation 1). The reactor was cooled to about 50°C, and the suspension was recovered manually for filtration. The solid portion was separated from the liquid portion and assayed for furfural and hydroxymethylfurfural (HMF) using HPLC. The total sugar concentration (g / l) in the liquid fraction of the conversion of oligomerized and polymerized sugars to monosaccharides was determined after dilute acid hydrolysis. The solid portion was washed with water (0.5 dm3) and pressurized. The ...

Embodiment 2

[0273] The suspension was prepared by mixing 33.8 kg of mashed wheat straw containing 11% moisture with 350 kg of tap water to give a consistency of 8.5%. The suspension was heated to about 60°C and the liquid part was separated from the solid by filtration in a stirred Nutsche Filter. The solid portion (31.2 kg dry matter) was mixed with water to give 192.4 kg of a suspension of 5% consistency. The suspension was heated to 180°C and cooled to room temperature, resulting in a severity of S = 4.15. The liquid part is separated from the solid part in a decanter centrifuge. The solid part was washed with water, and the washed insoluble part "autohydrolyzed straw" (15.3 kg dry matter) was recovered using a decanter centrifuge and stored in a refrigerator. Based on HPLC analysis, the liquid fraction (6.3 kg dry matter) contained hemicellulose-derived sugars, about half of its dry matter.

[0274] This example shows that autohydrolysis enables the separation of hemicellulose from...

Embodiment 3

[0278] The suspension was prepared by mixing 10.5 kg of 7.3% moisture ground wheat straw with 54.1 kg of tap water in a 100 dm3 container. After storage at room temperature for 18 h, 64.2 kg of the suspension was weighed into a horizontal cylindrical 250 dm3 stirred high pressure reactor. The reactor was closed and heated to 140 °C within 75 min, maintained at 140 °C for 5 h and cooled to room temperature within 30 min. The hydrothermally treated suspension was removed from the reactor and the solid fraction was isolated by filtration. The solid portion was washed with tap water and pressurized using a hydraulic press. The pressurized solids portion (20.9 kg) had a dry matter content of 42.7%.

[0279] The solid fraction produced from this experiment was used in subsequent delignification experiments, resulting in a solid fraction with low lignin and high carbohydrate content.

[0280] Delignification of self-hydrolyzed wheat straw

[0281] Autohydrolyzed wheat straw conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com