External temperature control type intelligent gas-sensitive analysis device

An analytical device and intelligent technology, applied in the direction of measuring device, analytical material, auxiliary controller with auxiliary heating device, etc., can solve the problems of inability to use sintered gas-sensing materials, complex process, complicated operation, etc., to achieve a wide range of applications , Wide measurement range and controllable heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

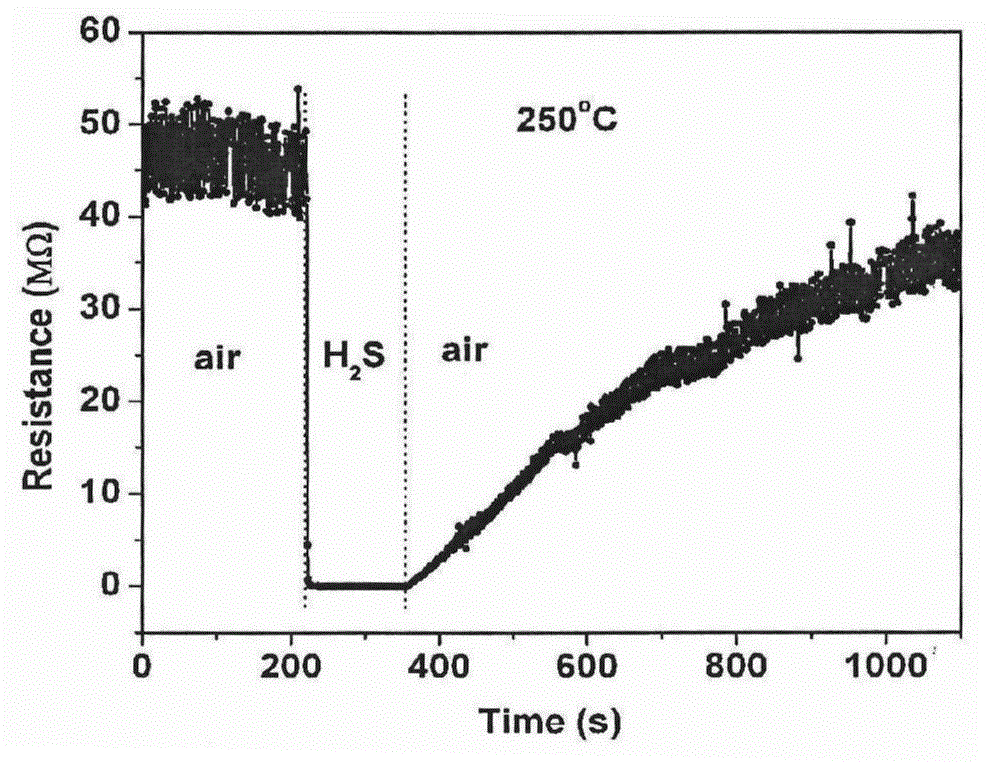

[0041] In this embodiment, the CZ-16 type Ce-doped ZnO powder of Beijing Zhongju Technology Co., Ltd. is used as a test sample to provide a specific method for the analysis of the gas-sensing characteristics of the above-mentioned gas-sensing analysis device.

[0042] The first method is the dynamic gas distribution test method under different pressures, the steps are as follows:

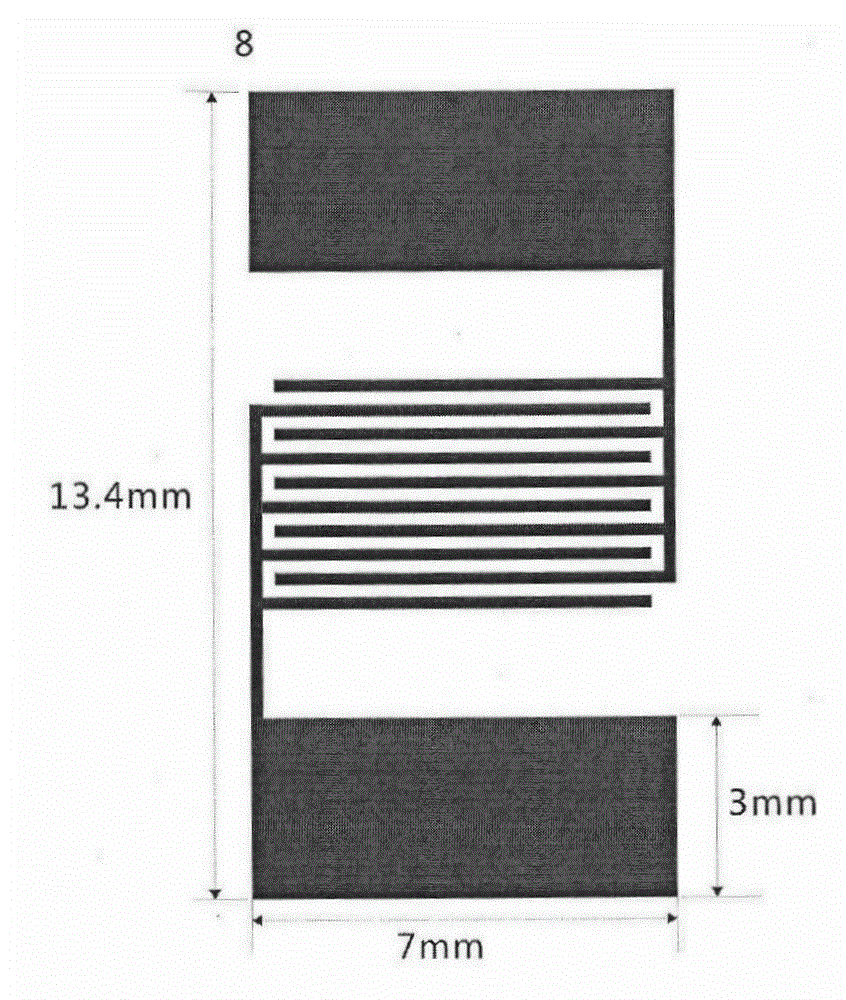

[0043] 1. Sample preparation method: mix the sample with a resistivity of 18.0MΩcm -1 mixed with deionized water to form a slurry, coated on the finger-shaped electrode part of the electrode substrate (8), and then dried at 60°C.

[0044] 2. Refer to figure 1 and 2 , place the prepared sample on the sample test platform (111), use the adjustment bracket (121) to adjust the position of the elastic probe (122), to ensure good contact between the probe and the sample to be tested.

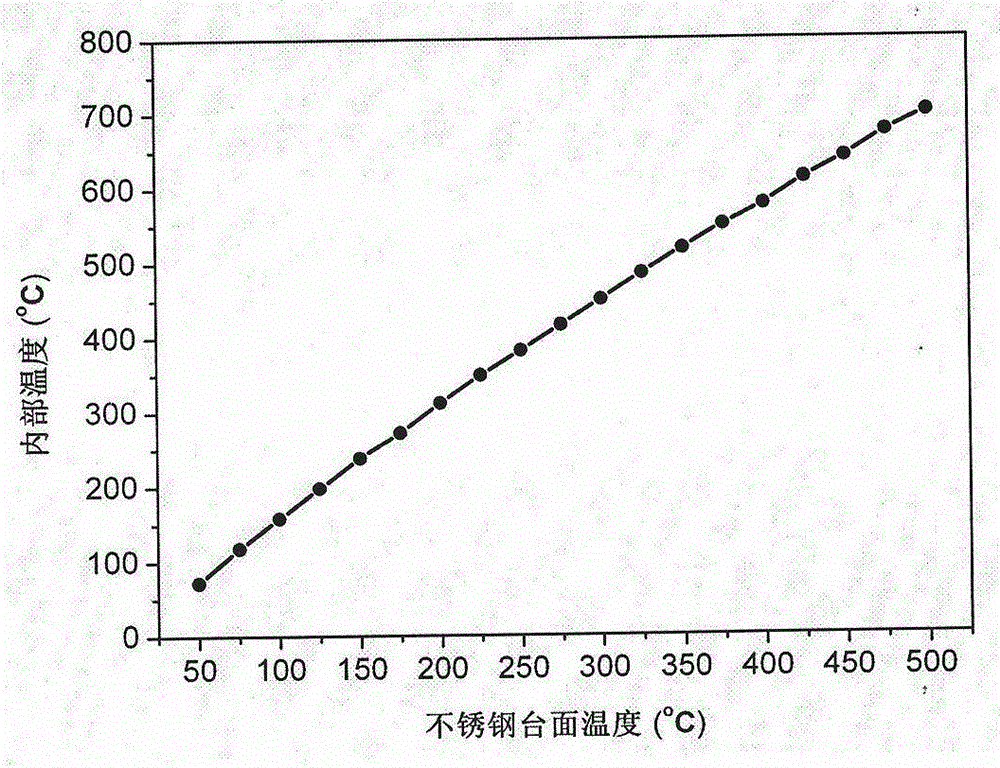

[0045] 3. Connect the circuit and turn on the test system, set the working temperature of the test sample on the touch...

Embodiment 2

[0059] This embodiment uses Beijing Elite Technology Co., Ltd. YSZ-103 type Y-doped ZrO 2 The thin film is used as a test sample to provide a specific method for the analysis of gas-sensing characteristics of the above-mentioned gas-sensing analysis device.

[0060] This embodiment supports the above three test methods at the same time, and the difference from Embodiment 1 is:

[0061] 1. The test sample is a thin film made on a silicon wafer. There is a Pt electrode made by magnetron sputtering at each of the two points of the thin film, so no other substrate is needed, and the test only needs to be pressed on the Pt electrode with a probe.

[0062] 2. Change the test mode to voltage test mode. Figure 9 Typical test results for 10ppm NO at 400°C under dynamic gas distribution are given.

Embodiment 3

[0064] This example uses the PW-115 type WO of Beijing Zhongju Technology Co., Ltd. 3 The nanotube is used as a test sample to provide a specific method for analyzing the gas-sensing characteristics of the above-mentioned gas-sensing analysis device.

[0065] This embodiment supports the above three test methods at the same time, and the difference from Embodiment 1 is:

[0066] 1. Change the test mode to current test mode. Figure 10 The test results of the test sample against the static configuration of 100ppm ethanol at 200°C are given.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outside diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com