Graphene and metal nanowire composite transparent and conductive plastic film, manufacturing method and application thereof

A technology of metal nanowires and graphene films, which is applied in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve problems such as instability, inapplicability for long-term applications, and large surface resistance, so as to resist aging impact, excellent light transmittance and electrical conductivity, good effect of anti-peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

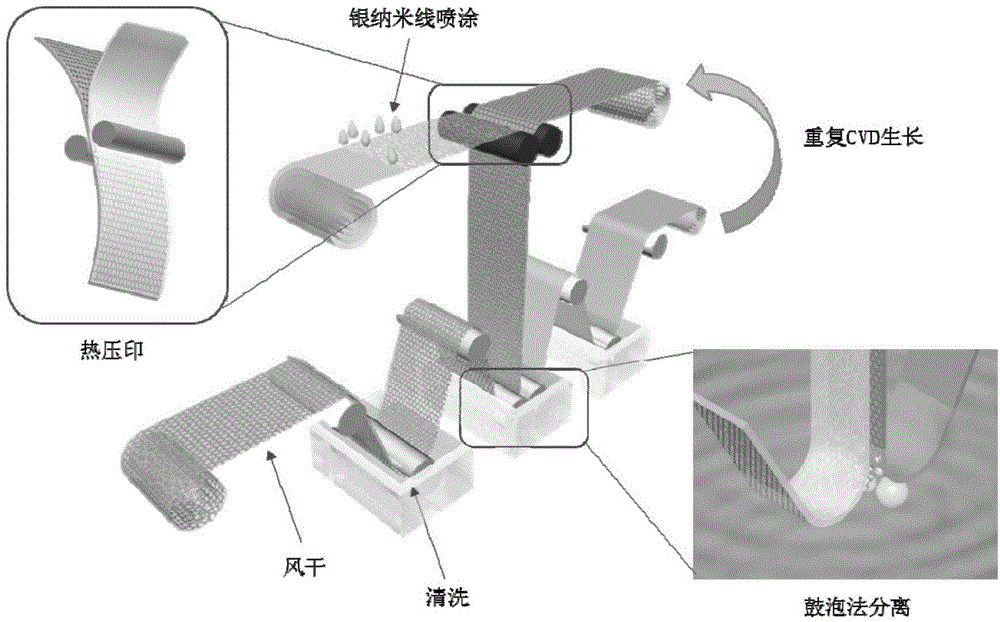

[0074] Embodiment 1, preparation graphene and silver nanowire composite transparent conductive plastic film

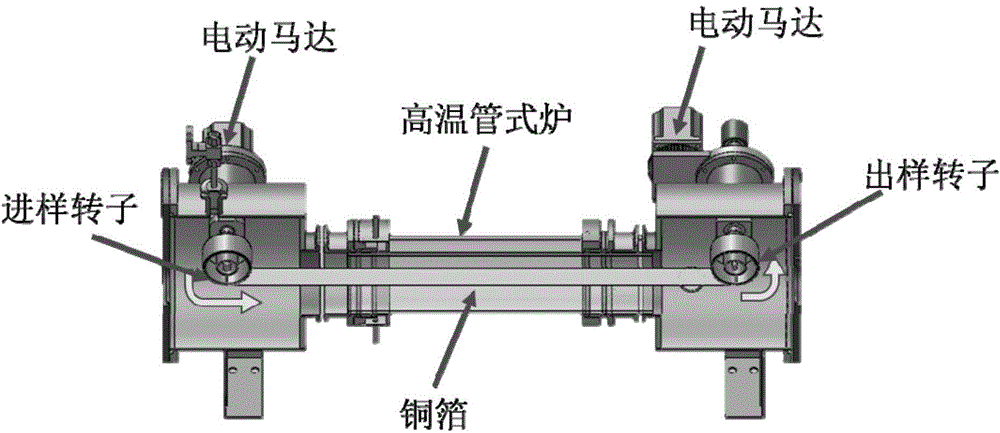

[0075] 1) Single-layer graphene film / copper foil: use industrial electrolytic copper foil, cut the copper foil into 10cm x 5m (width x length), place it in the operating system of the continuous production system, and under the hydrogen atmosphere with a flow rate of 50sccm, Raise the temperature of the furnace body to 1000°C, the system pressure is about 50Pa, then change the hydrogen flow rate to 2sccm, feed 36sccm methane gas, keep at 1000°C, and use a stepping motor to control the running speed of the copper foil to 1r / min. The foil is attached to the wall of the quartz tube. After the operation, the hydrogen and methane are turned off to obtain a large area of single-layer graphene deposited on the surface of the copper foil. After the copper foil is lowered to room temperature, the furnace is opened and the copper foil is taken out;

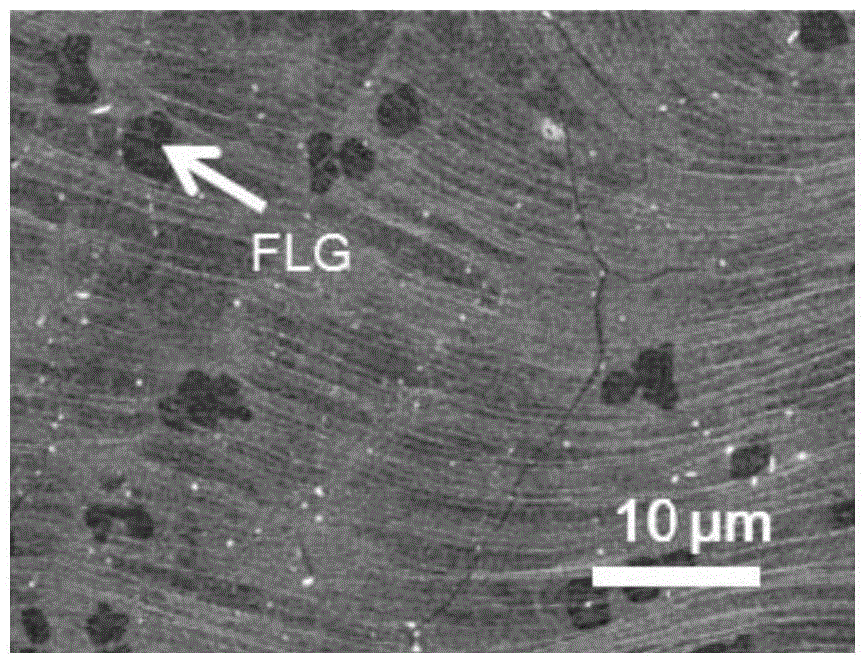

[0076] The typical electro...

Embodiment 2

[0108] Embodiment 2, preparation graphene and copper nanowire composite transparent conductive plastic film

[0109] 1) single-layer graphene film / copper foil: step is with embodiment 1 step 1);

[0110] 2) Preparation of PET / EVA / Cu NWs composite plastic film: use commercial thermal lamination film PET / EVA, clean the PET / EVA film with isopropanol, dry it, and then treat it with 90W air plasma for 2min to improve the EVA surface hydrophilicity;

[0111] Disperse metallic copper nanowires in ethanol to a concentration of 10 mg / mL. Before use, dilute the Cu NWs suspension to 1 mg / mL with ethanol, and ultrasonically disperse in an ultrasonic cleaner with a power of 99W for 1 min to obtain a dispersed Uniform suspension of metallic copper nanowires;

[0112] Forming the metal copper nanowire layer on the PET / EVA film can adopt the following process 1 or process 2:

[0113] Process 1: Spin-coating process of the homogenizer, adjust the concentration of copper nanowires of differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com