Modified nitrogen control material prepared from lake sediments, preparation method and application thereof

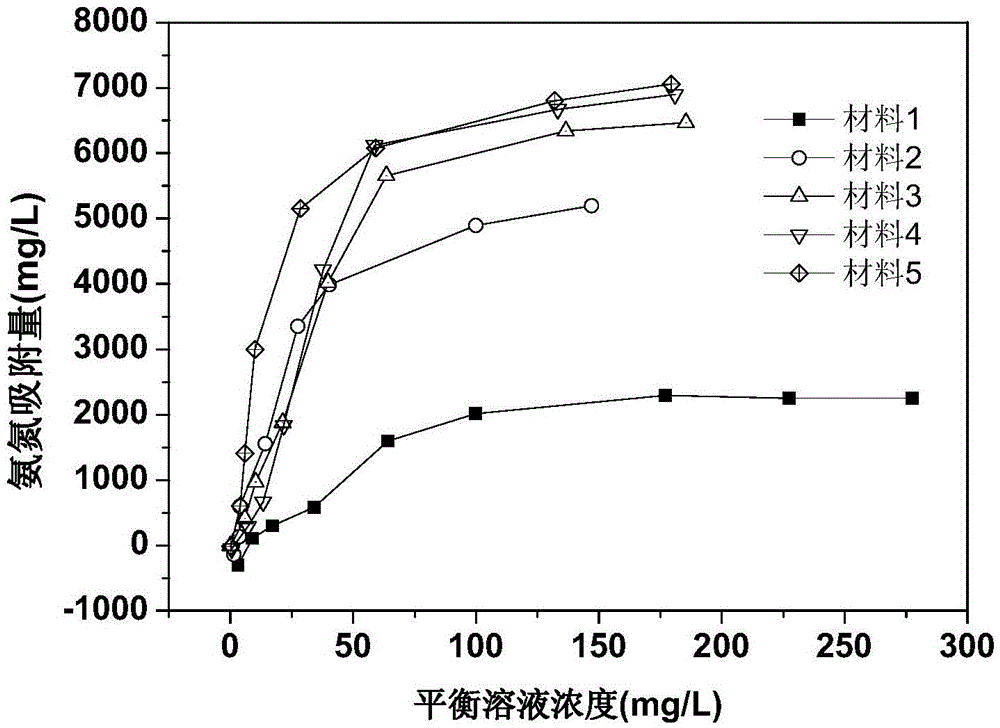

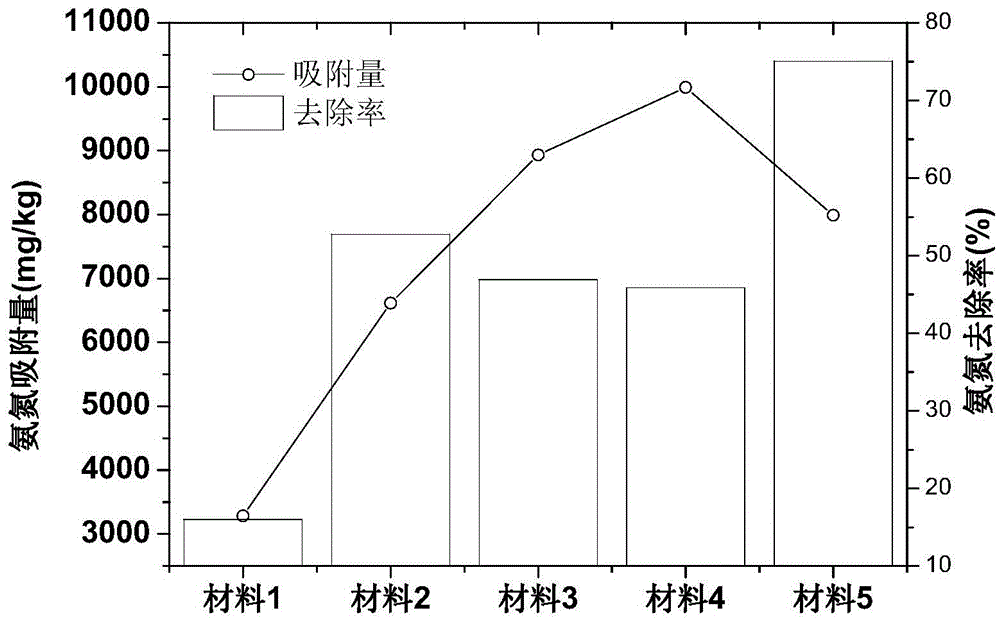

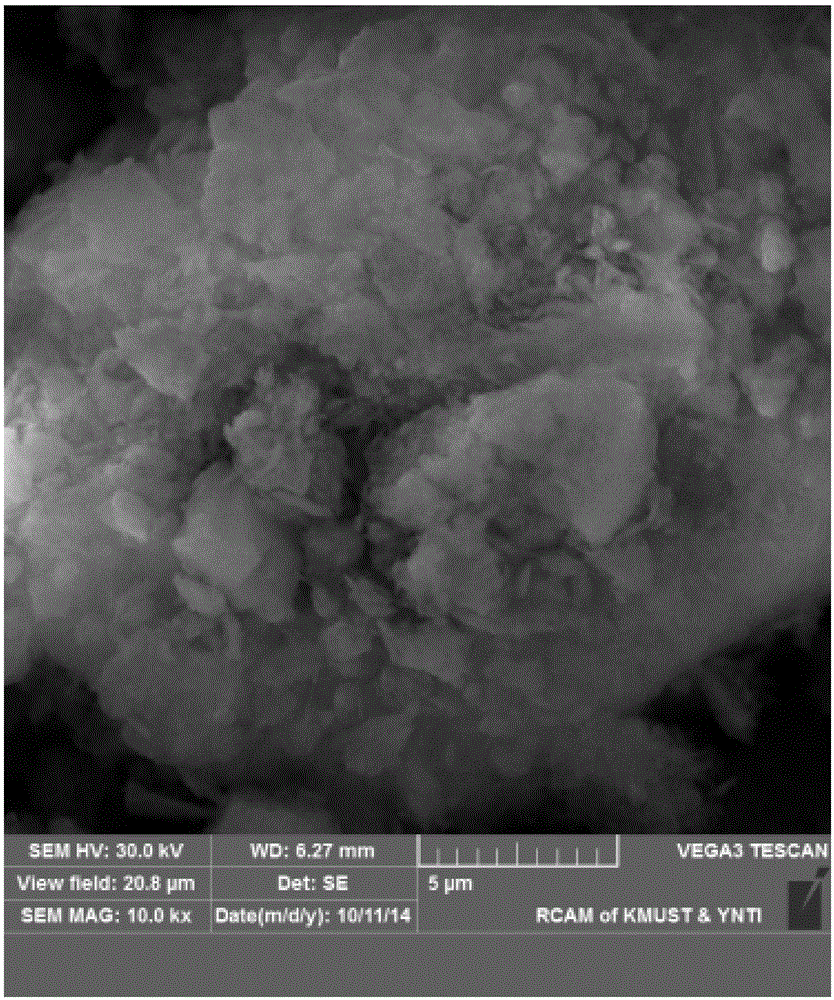

A sediment and modification technology, which is applied in the field of modified nitrogen control materials and its preparation, can solve the problems of weak ammonia nitrogen adsorption effect, poor ecological safety, and high cost, and achieve the solution of weak ammonia nitrogen adsorption effect, high safety, The effect of increasing the total pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The method for preparing modified nitrogen-controlling materials using lake sediments described in this embodiment comprises the following steps:

[0059] (1) Collect lake sediments, freeze-dry, grind through a 20-mesh sieve, and set aside; wherein, the Al in the lake bottom mud 2 0 3 Content is 30%, Fe 2 o 3 content of 10%, CaO content of 20%, MgO content of 8%, K 2 The O content is 1%, and the others are 31%; the loss on ignition of the lake bottom mud is 30.43%;

[0060] (2) Take the lake sediment treated in step (1) and place it in a muffle furnace for constant temperature heating treatment, the heating temperature is 50°C, heat for 0.5 hour, then cool to room temperature, and set aside;

[0061] (3) Add zeolite in proportion to the lake sediment after step (2), the sediment accounts for 5% of the total mass of the sediment and zeolite mixture, mix well, then add sodium chloride solution and a mixed solution of magnesium hydroxide solution, the amount of the mi...

Embodiment 2

[0063] The method for using the modified nitrogen-controlling material prepared from lake sediments described in this embodiment comprises the following steps:

[0064] (1) Collect lake sediments, freeze-dry, grind through a 200-mesh sieve, and set aside; wherein, the SiO in the lake bottom mud 2 Content is 30%, Al 2 0 3 Content is 30%, Fe 2 o 3 The CaO content is 30%, the CaO content is 1%, and the others are 9%; the loss on ignition of the lake bottom mud is 30.8%;

[0065] (2) Take the lake sediment treated in step (1) and place it in a muffle furnace for constant temperature heating treatment, the heating temperature is 900°C, heat for 3.5 hours, then cool to room temperature, and set aside;

[0066](3) Add zeolite in proportion to the lake sediment after step (2), the sediment accounts for 90% of the total mass of the sediment and zeolite mixture, mix well, then add magnesium chloride solution and hydrogen The mixed solution of sodium oxide solution, the added amount...

Embodiment 3

[0068] The method for using the modified nitrogen-controlling material prepared from lake sediments described in this embodiment comprises the following steps:

[0069] (1) collect lake sediment, through freeze-drying, grind through 50 mesh sieves, for subsequent use;

[0070] (2) Take the lake sediment treated in step (1) and place it in a muffle furnace for constant temperature heating treatment. The heating temperature is 100° C., heated for 1 hour, then cooled to room temperature, and set aside;

[0071] (3) Add zeolite in proportion to the lake sediment after step (2), the sediment accounts for 80% of the total mass of the sediment and zeolite mixture, mix well, then add calcium chloride solution and a mixed solution of potassium hydroxide solution, the amount of the mixed solution added is 20 times the volume of the sediment after the step (2) is processed, and the concentration of calcium chloride in the mixed solution is 0.5mg / L , adjust the pH value of the mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com