Method for preparing three-dimensional rare earth oxide nanorod framework loaded noble metal nanoparticles

A rare earth oxide and nanoparticle technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc. Recession and other problems, to achieve the effect of enhanced catalytic oxidation activity, high structural stability, and promotion of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

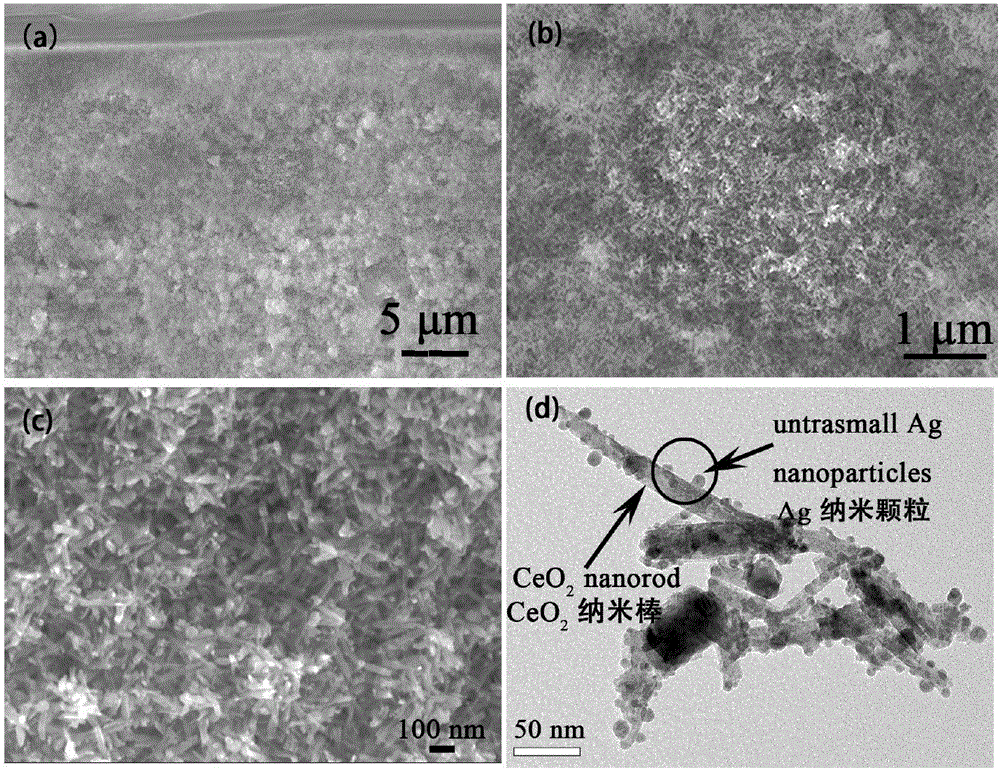

[0020] The steps of this embodiment include: the raw material prepared by the molar ratio of 79% Al, 6% Ce and 15% Ag is heated to 700 ° C by electric arc under vacuum to melt into a uniform precursor alloy, and then prepared into cast alloy by ordinary casting method. Ingot; the alloy ingot is melted twice in a melt quenching furnace with a protective atmosphere of 0.1MPa and heated to 750°C, and the thin strip is prepared by the melt quenching method; the thin strip is prepared in a 5% NaOH aqueous solution at 60°C Dealloy and corrode in a water bath for 12 hours. After there are no obvious bubbles, wash it repeatedly with deionized water and alcohol. After cleaning, place it in a constant temperature drying oven at 50°C for 2 hours, and then bake it in an air atmosphere furnace at 400°C for 1 hour. Finally, the cerium oxide-supported nano-silver particle nano-three-dimensional framework composite material is prepared.

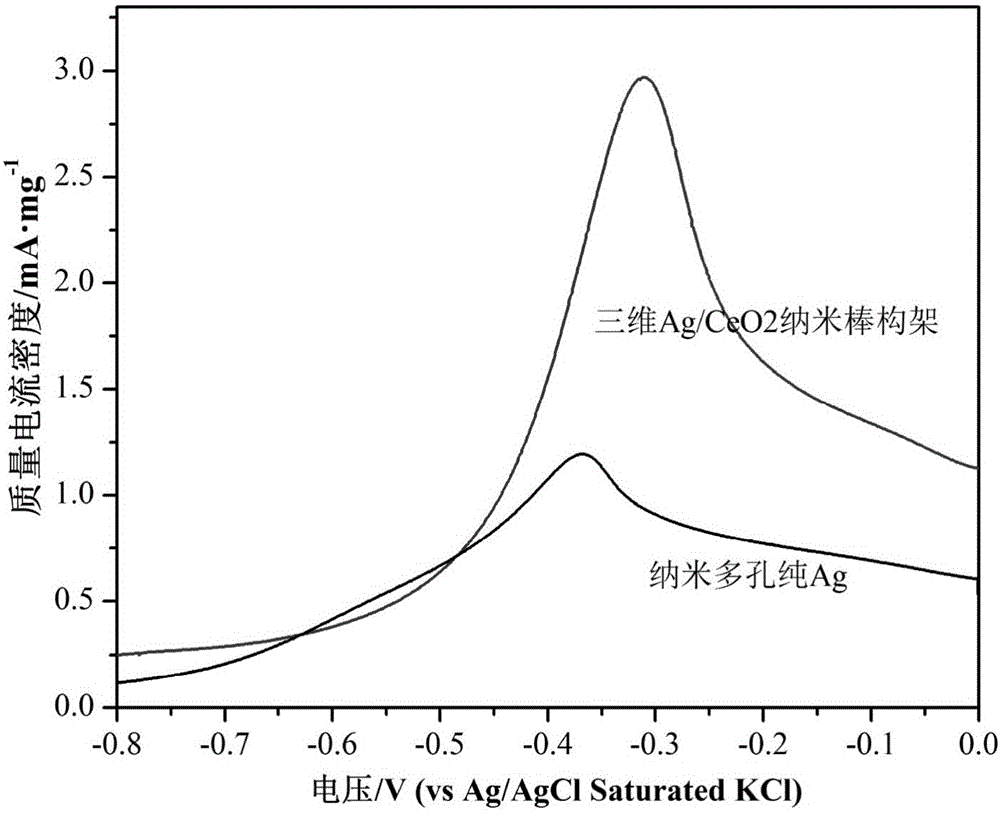

[0021] The resulting nanocomposites exhibit high activ...

Embodiment 2

[0023] The raw material prepared by molar ratio of 89.7% Al, 10% Ce and 0.3% Au is heated to 750°C by arc melting under argon protective atmosphere to melt into a uniform precursor alloy, and then prepared into an ingot by ordinary casting method; the alloy The ingot is melted twice in a melt quenching furnace with a protective atmosphere of 0.1MPa and heated to 800°C, and the thin strip is prepared by the melt quenching method; the thin strip is dealloyed and corroded in a 10% NaOH aqueous solution After 12 hours, when there are no obvious bubbles, wash it repeatedly with deionized water and alcohol. After cleaning, place it in a constant temperature drying oven at 50°C for 2 hours; then bake it in an air atmosphere furnace at 400°C for 1 hour to obtain cerium oxide. Nano-silver particle-loaded nano-three-dimensional framework composite material.

[0024] It exhibits high activity for CO catalytic oxidation, and the conversion rate can reach 20% at room temperature.

Embodiment 3

[0026] The raw material prepared by the molar ratio of 84% Al, 6% Ce and 10% Ag is heated to 600 ° C by electric arc under vacuum to melt into a uniform precursor alloy, and then prepared into ingot by ordinary casting method; the alloy ingot is cast at 0.1 The thin strip was prepared by melt quenching method in the melt quenching furnace under MPa protection atmosphere and heated to 650°C for the second time; the thin strip was dealloyed and corroded in a water bath of 5% NaOH aqueous solution at 60°C for 13 hours, after there are no obvious bubbles, wash it repeatedly with deionized water and alcohol, dry it in a constant temperature drying oven at 50°C for 2 hours, and then bake it in an air atmosphere furnace at 400°C for 1 hour to prepare ceria-loaded Nano silver particle nano three-dimensional framework composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com