Triazole wood bamboo anticorrosion and anti-discoloration composition and preparation method thereof

A composition and technology for bamboo materials, which are applied in the directions of wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of not being used to improve the anti-loss performance of preservative components, corrosion of metal pressure treatment equipment parts, and inability to maintain the true color of wood, etc. To achieve the effect of low preparation and use price, excellent anticorrosion, and improved anti-bleeding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

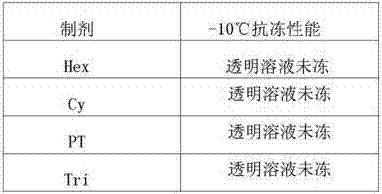

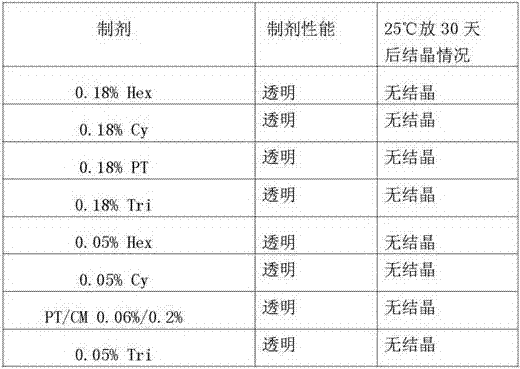

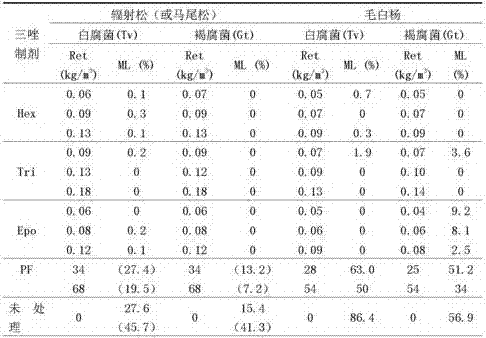

[0053] (2) The preparation of the triazole composition working solution and the first pressurized treatment and drying method for wood and bamboo, the prepared triazole concentrate is diluted with water, and then added to the CMIT / MIT solution to mix and dilute to obtain the triazole Composition working solution.

[0054] That is, (1) and (2) are: first prepare the triazole concentrated solution, and the weight percentage of each component in the triazole concentrated solution is composed of: 4.1% to 15.6% of triazole compounds, ethanol and N,N-dimethylformaldehyde The combination of amide (DMF) is 33.6-67%, the combination of amine oxide and quaternary ammonium salts or the combination of dodecylbenzenesulfonate calcium salt and fatty alcohol polyoxyethylene ether (MOA-15) is 20.7-26.5%, and the rest is water; Wherein the triazole compound is a combination of hexaconazole, cyproconazole, econazole, triaconazole, propiconazole / tebuconazole 1:0.68-0.95. Add some water to the t...

Embodiment 1

[0059] Example 1 The preparation method of hexaconazole (Hex) stoste

[0060] Weigh 210g 95% hexaconazole into a 2000ml small reactor, add 400g 95% ethanol and 200g DMF, after the hexaconazole dissolves, add 73g 30% dodecyl dimethyl amine oxide (OA-12)) and 440g 99% Octadecyltrimethylammonium Chloride, use a stirrer to stir for 10 minutes at a speed of 300-1000r / min. After stirring evenly, a water-soluble hexaconazole preparation, referred to as Hex, is obtained. The weight percentage of each component is: 15.0% of hexaconazole, 43.8% of ethanol and DMF, dodecyl dimethylamine oxide and octadecyl tris The methyl ammonium chloride surfactant is 24.9%, the rest is water, and the ratio of lauryl dimethyl ammonium oxide to octadecyl trimethyl ammonium chloride is 1:14. Add a certain multiple of water to dilute to obtain different concentrations of Hex.

Embodiment 2

[0061] Example 2 The preparation method of epoxiconazole (Epo)

[0062] Weigh 36g of 98% epoxiconazole into a 2000ml small reaction kettle, add 400g of 95% ethanol and 200g of DMF, after the epoxiconazole is dissolved, add 110g of 70% calcium dodecylbenzenesulfonate and 110g of MOA-15 . The stirrer rotates at 300-1000r / min and stirs for 10 minutes. Stir evenly to obtain epoxiconazole, referred to as Epo preparation, the weight percentage of each component is composed of: epoxiconazole 4.1%, ethanol and DMF 67%, dodecylbenzenesulfonate calcium salt and MOA-15 are 1.8% . Add 718 times of 25% ethanol to dilute to obtain 0.0057% Epo.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com