Carbon quantum dot fluorescent labeling material using coke powder as carbon source and preparation method thereof

A carbon quantum dot and fluorescent labeling technology, which is applied in the field of carbon quantum dot fluorescent labeling materials and their preparation, can solve the problems of low fluorescence yield of carbon quantum dots, harsh preparation conditions, difficult separation and purification, etc., and achieves easy emission and optical performance. Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

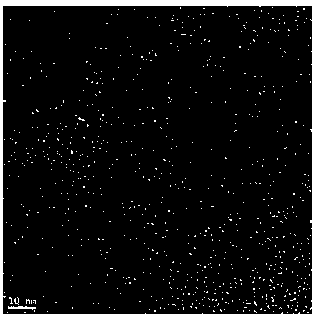

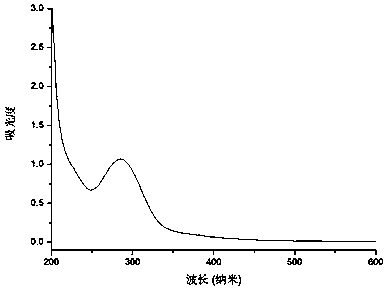

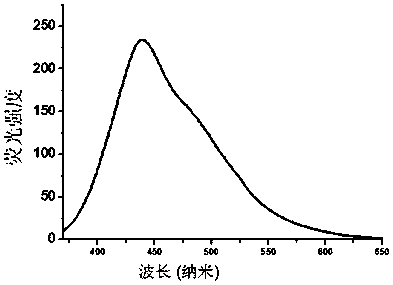

Image

Examples

Embodiment 1

[0041] A carbon quantum dot fluorescent labeling material using coke powder as a carbon source and a preparation method thereof. The concrete steps of the method described in this embodiment are:

[0042] (1) Pressed coke powder: Concentrated H 2 SO 4 : Concentrated HNO 3 The mass ratio is 0.1:(11~13):(2~4), the coke powder is placed in the reaction kettle first, and then concentrated H 2 SO 4 and concentrated HNO 3 mixed acids to obtain a black mixture.

[0043] (2) Stir the black mixture at 95-105° C. for 11-12 hours, cool naturally, and separate the solid and liquid; add NaOH solution to the separated liquid to adjust the pH value to 7-9 to obtain a brown-black liquid.

[0044] (3) According to the volume ratio of brown-black liquid: acetone: isopropanol is 1: (1~1.5): (1.3~1.8), add acetone and isopropanol to the brown-black liquid, stir for 10~20min, Centrifuge at 6000~9000r / min for 30~40min, remove the supernatant, and obtain the lower layer solution.

[0045] (4...

Embodiment 2

[0048] A carbon quantum dot fluorescent labeling material using coke powder as a carbon source and a preparation method thereof. The concrete steps of the method described in this embodiment are:

[0049] (1) Pressed coke powder: Concentrated H 2 SO 4 : Concentrated HNO 3 The mass ratio is 0.1:(9~11):(3~4), the coke powder is placed in the reaction kettle first, and then concentrated H 2 SO 4 and concentrated HNO 3 mixed acids to obtain a black mixture.

[0050] (2) Stir the black mixture at 95-105° C. for 10-11 hours, cool naturally, and separate the solid and liquid; add NaOH solution to the separated liquid to adjust the pH value to 7-9 to obtain a brown-black liquid.

[0051] (3) According to the volume ratio of brown-black liquid: acetone: isopropanol is 1: (1~1.5): (1.5~2), add acetone and isopropanol to the brown-black liquid, stir for 10~20min, Centrifuge at 6000~9000r / min for 40~50min, remove the supernatant, and obtain the lower layer solution.

[0052] (4) A...

Embodiment 3

[0055] A carbon quantum dot fluorescent labeling material using coke powder as a carbon source and a preparation method thereof. The concrete steps of the method described in this embodiment are:

[0056] (1) Pressed coke powder: Concentrated H 2 SO 4 : Concentrated HNO 3 The mass ratio is 0.1:(13~15):(4~5), put the coke powder in the reaction kettle first, then add concentrated H 2 SO 4 and concentrated HNO 3 mixed acids to obtain a black mixture.

[0057] (2) Stir the black mixture at 95-105° C. for 8-10 hours, cool naturally, and separate the solid and liquid; add NaOH solution to the separated liquid to adjust the pH value to 7-9 to obtain a brown-black liquid.

[0058] (3) According to the volume ratio of brown-black liquid: acetone: isopropanol is 1: (1~1.5): (1~1.5), add acetone and isopropanol to the brown-black liquid, stir for 10~20min, Centrifuge at 6000~9000r / min for 50~60min, remove the supernatant, and obtain the lower layer solution.

[0059] (4) Accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com