Method for preparing zirconium oxide nanometer fiber through bubble spinning

A technology of bubble spinning and nanofiber, applied in fiber processing, electrospinning, fiber chemical characteristics and other directions, can solve the problem of no similar products, etc., and achieve the effects of low cost, simple and convenient inhibitory effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

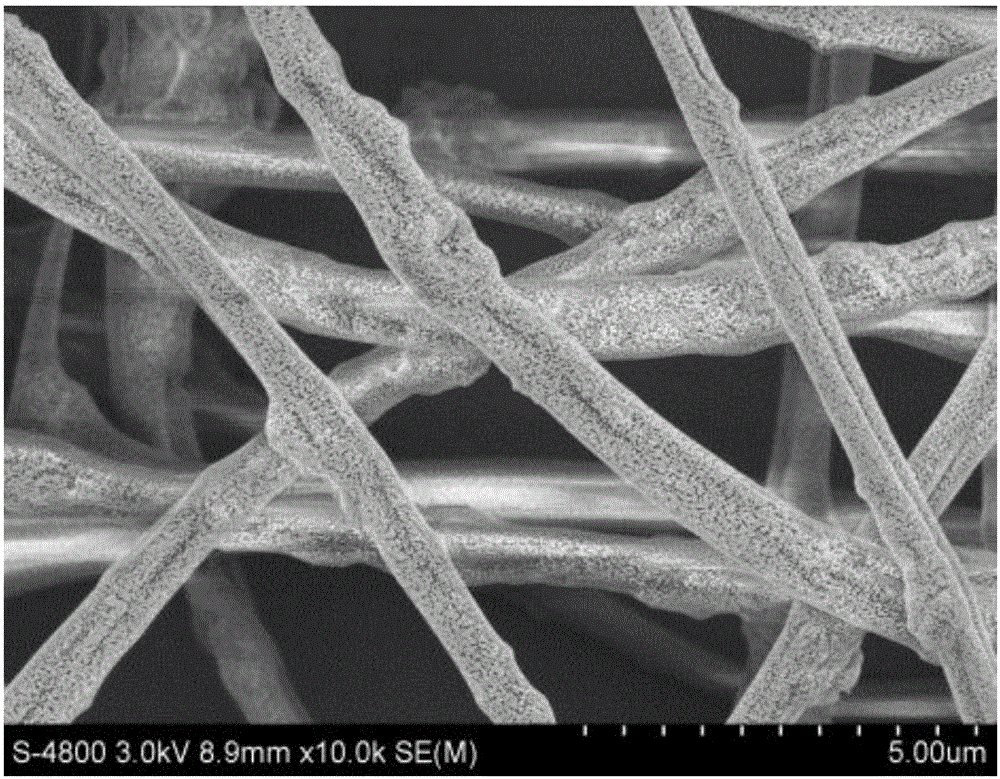

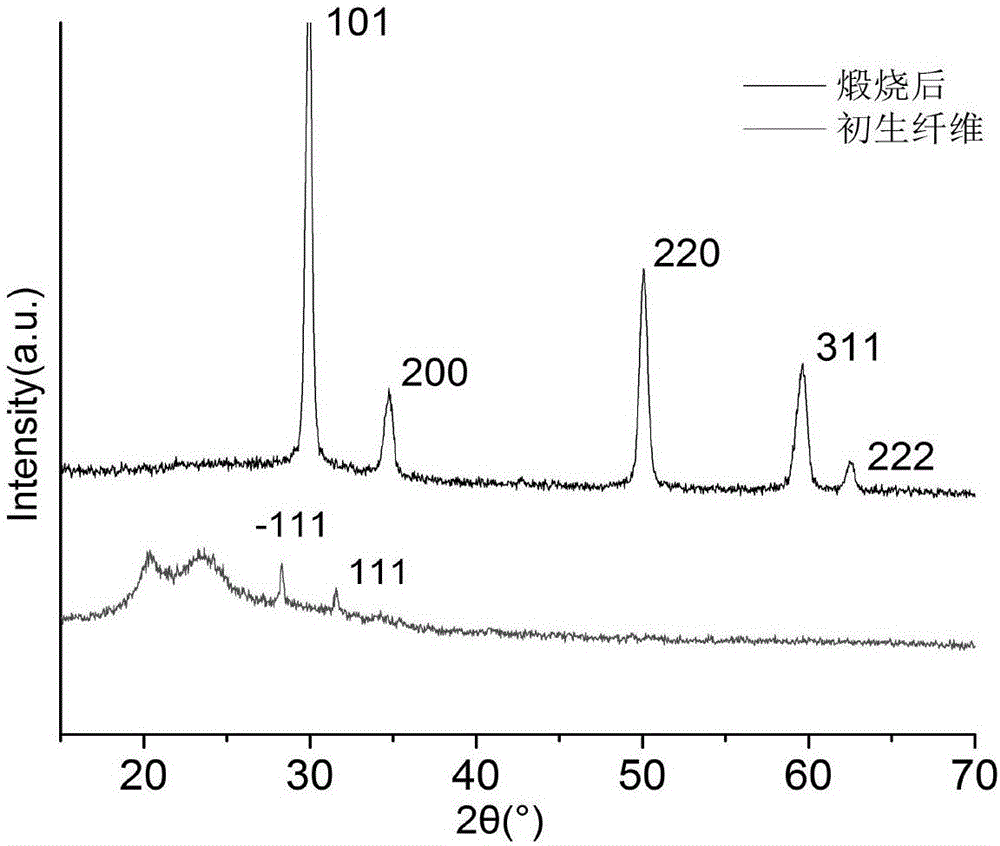

[0049] A kind of as-spun fiber is the method for the bubble spinning of polyacrylonitrile (PAN) to prepare zirconia nanofiber, and its processing route is as follows:

[0050] (1) First, dissolve 1g of zirconium oxychloride (Cl2OZr) in 1g of N-N dimethylacetamide (DMAC) solvent, then add it into a water bath and stir it into a complete solution at 60°C; Nitrile 1.5g (PAN) was dissolved in 12.5gN-N dimethylacetamide (DMAC) solvent, then added to a water bath and stirred at 90°C to form a complete solution; then the two solutions were mixed, and 0.2gZrO2 was added Nanoparticle stabilizer and 0.3g polyethylene glycol, and finally stir evenly in an ultrasonic mixer for 3h to become the final bubble spinning solution;

[0051] (2) Add the spinning solution to the spinning solution tank of the rotary bubble spinning, and connect the positive spinneret to the high-voltage power supply for bubble spinning, and connect the negative pole to the receiving plate, the receiving distance is...

Embodiment 2

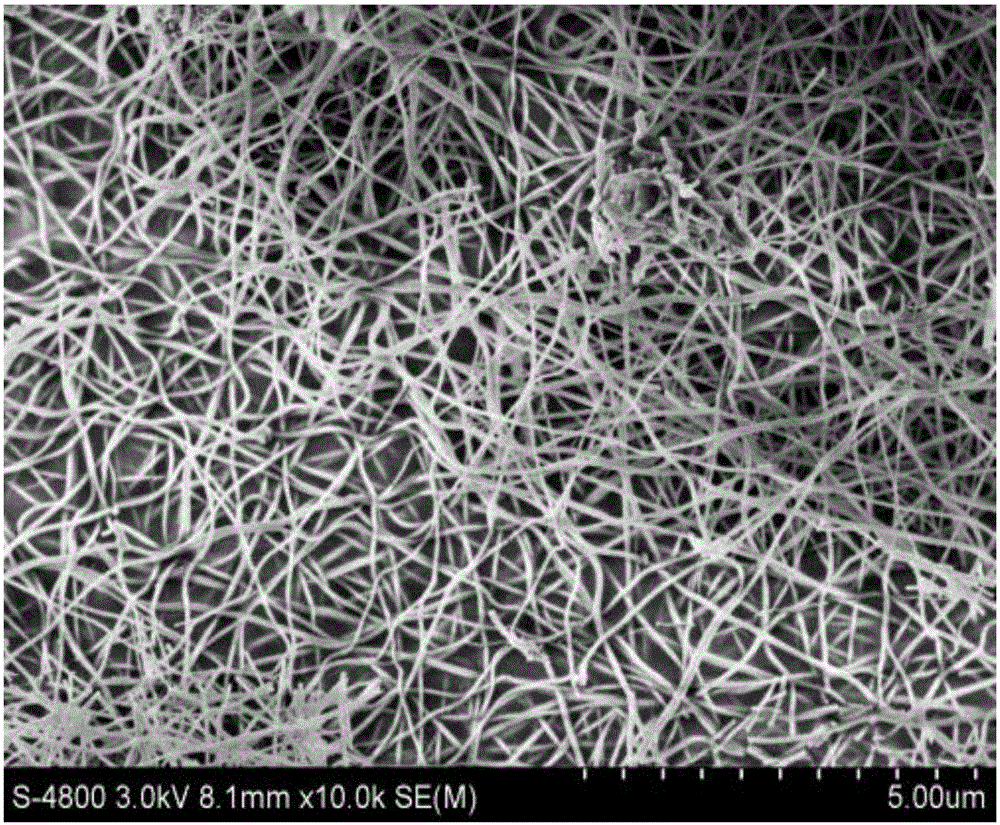

[0055] A kind of as-spun fiber is the method for the bubble spinning of polyvinyl alcohol (PVA) to prepare zirconia nanofiber, and its process route is as follows:

[0056] (1) First dissolve 1.5g of zirconium acetate in 3g of deionized water, then stir it into a complete solution at room temperature; at the same time dissolve 4.5g of polyvinyl alcohol (PVA) in 42g of deionized water, and then add it to the water bath Stir at 90°C to form a complete solution state; then mix the two solutions, add 0.5g yttrium oxide (Y2O3) nanoparticle stabilizer and 0.5g polyethylene glycol, and finally stir evenly in an ultrasonic stirrer for 2h to become the final solution. Bubble spinning solution;

[0057] (2) Add the spinning solution to the spinning solution tank of the rotary bubble spinning, and connect the positive spinneret to a high-voltage power supply for bubble spinning, and connect the negative pole to the receiving plate with a receiving distance of 15cm. Under the condition o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com