Manganese dioxide/polypyrrole composite electrode free of binder, preparation method and application of manganese dioxide/polypyrrole composite electrode

A manganese dioxide and composite electrode technology, used in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, electrolytic coatings, etc., can solve the problems of low specific capacity and poor rate performance, improve utilization, and reduce overall resistance. , the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The cleaned nickel foam is cut into 1X2 cm 2 The size, immersed in 0.05 mmol / L potassium permanganate solution, transferred to the reaction kettle, placed in 160 0 In the oven of C, continue to react for 24 hours. After the reactor was naturally cooled to room temperature, it was washed with deionized water and absolute ethanol. Add 1 mol of potassium chloride and 0.05 mol of pyrrole into 1 L of deionized solution to form an electrolyte. The above-mentioned foamed nickel sheet loaded with manganese dioxide was immersed in the electrolyte, and the constant potential electrochemical deposition was carried out at a voltage of 0.9V for 60s, 120s, 180s, 240s, and 300s respectively.

Embodiment 2

[0027] The cleaned nickel foam is cut into 1X2 cm 2 Dip it into 0.05 mmol / L potassium permanganate solution, transfer it to the reaction kettle, put it in 160 0 In the oven of C, continue to react for 24 hours. After the reactor was naturally cooled to room temperature, it was washed with deionized water and absolute ethanol. Add 0.4 mol of disodium hydrogen phosphate, 0.3 mol of pyrrole and 0.002 mol of sodium perchlorate into 1 L of deionized solution to form a pyrrole electrolyte. The above-mentioned foamed nickel sheet loaded with manganese dioxide was immersed in the electrolyte, and the constant potential electrochemical deposition was carried out at a voltage of 0.9V for 60s, 120s, 180s, 240s, and 300s respectively.

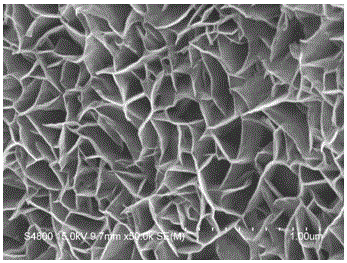

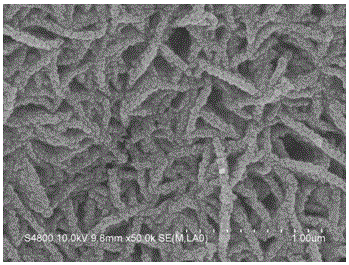

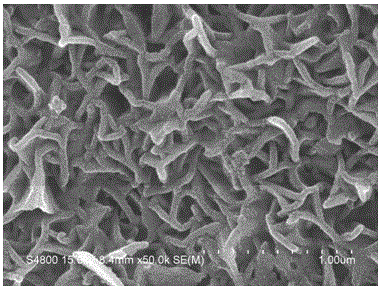

[0028] The morphology of the manganese dioxide and the manganese dioxide / polypyrrole composite material prepared in Examples 1 and 2 above was characterized by a field emission scanning electron microscope (JEOL JSM-4800). figure 1 A scanning electron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com