Nitrogen-doped rod-like titanium oxide/two-dimensional laminated titanium carbide nanometer composite electrode material, and preparation method and application therefor

A nanocomposite material, two-dimensional layered technology, applied in hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, nanotechnology for materials and surface science, etc., can solve the problem of low nitrogen doping content, achieve High specific capacity, good rate performance and cycle stability, novel shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

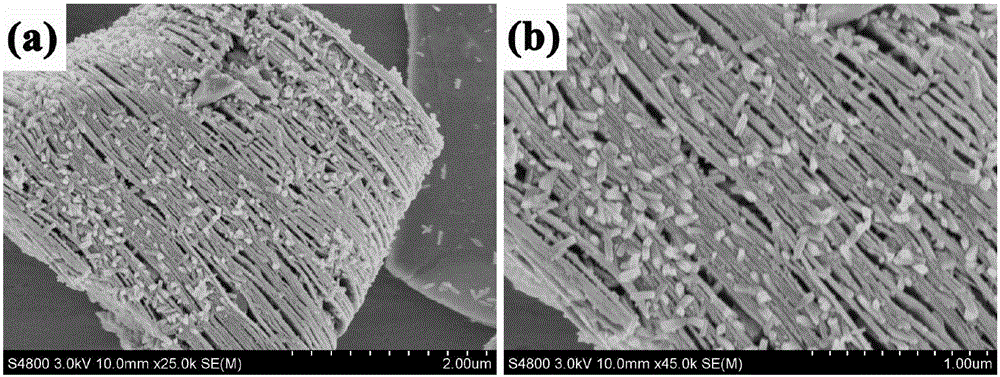

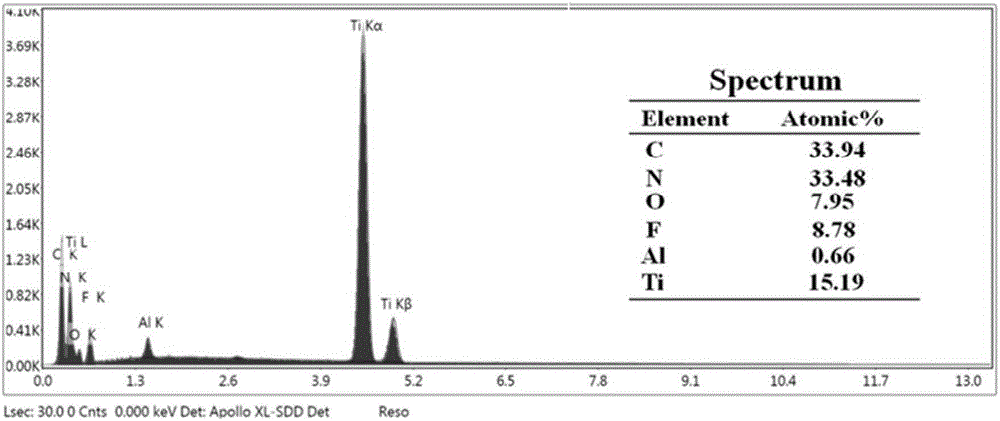

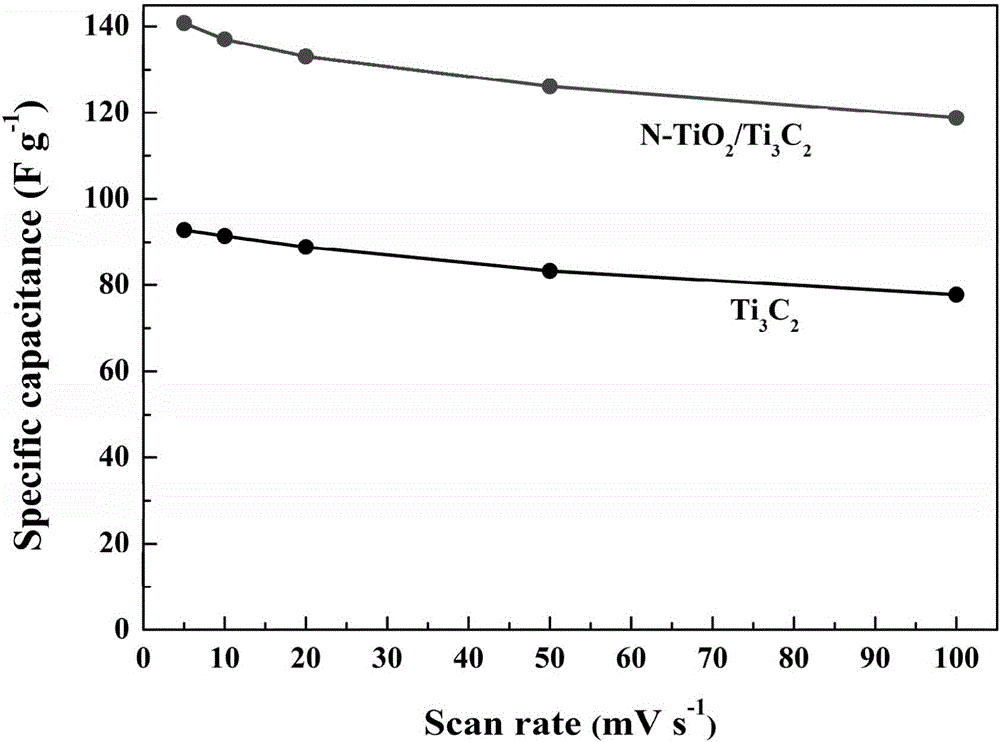

[0020] In the nitrogen-doped rod-shaped titanium oxide / two-dimensional layered titanium carbide nanocomposite electrode material of this embodiment, the rod-shaped titanium oxide is distributed on the surface of the sheet and between the sheets, and its nitrogen content accounts for 33.48% of the total atomic percentage.

[0021] A method for preparing a nitrogen-doped rod-shaped titanium oxide / two-dimensional layered titanium carbide nanocomposite electrode material, comprising the following steps:

[0022] Step 1, take Ti 3 C 2 Stir and mix 50mg of powder with 50mL urea aqueous solution for 0.5h, the mass ratio of urea:water in urea aqueous solution is 1:0.5;

[0023] Step 2, put the solution obtained in Step 1 into a hydrothermal kettle, heat it at 180°C for 12 hours, then wash the reacted powder with deionized water and absolute ethanol several times, and then put it into a vacuum at 40°C drying in an oven to obtain the active material—nitrogen-doped rod-shaped titanium ...

Embodiment 2

[0032] In the nitrogen-doped rod-shaped titanium oxide / two-dimensional layered titanium carbide nanocomposite electrode material of this embodiment, the rod-shaped titanium oxide is distributed on the surface of the sheet and between the sheets, and its nitrogen content accounts for about 25% of the total atomic percentage.

[0033] A method for preparing a nitrogen-doped rod-shaped titanium oxide / two-dimensional layered titanium carbide nanocomposite electrode material, comprising the following steps:

[0034] Step 1, take Ti 3 C 2 Stir and mix 50mg of powder with 50mL urea aqueous solution for 2 hours, the mass ratio of urea:water in urea aqueous solution is 1:1;

[0035] Step 2, put the solution obtained in step 1 into a hydrothermal kettle, heat it at 160°C for 12 hours, then wash the reacted powder with deionized water and absolute ethanol several times, and then put it into a vacuum at 40°C drying in an oven to obtain the active material—nitrogen-doped rod-shaped titan...

Embodiment 3

[0041] In the nitrogen-doped rod-shaped titanium oxide / two-dimensional layered titanium carbide nanocomposite electrode material of this embodiment, the rod-shaped titanium oxide is distributed on the surface of the sheet and between the sheets, and its nitrogen content accounts for 22% of the total atomic percentage.

[0042] A method for preparing a nitrogen-doped rod-shaped titanium oxide / two-dimensional layered titanium carbide nanocomposite electrode material, comprising the following steps:

[0043] Step 1, take Ti 3 C 2 Stir and mix 50mg of powder with 50mL urea aqueous solution for 4 hours, the mass ratio of urea:water in urea aqueous solution is 1:2;

[0044] Step 2, put the solution obtained in step 1 into a hydrothermal kettle, heat it in water at 200°C for 12 hours, then wash the reacted powder with deionized water and absolute ethanol several times, and then put it in a vacuum at 40°C drying in an oven to obtain the active material—nitrogen-doped rod-shaped tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com