Methods for producing starch selenium polysaccharide and selenium-rich pre-gelatinized nutritional rice paste by using pulsed electric fields

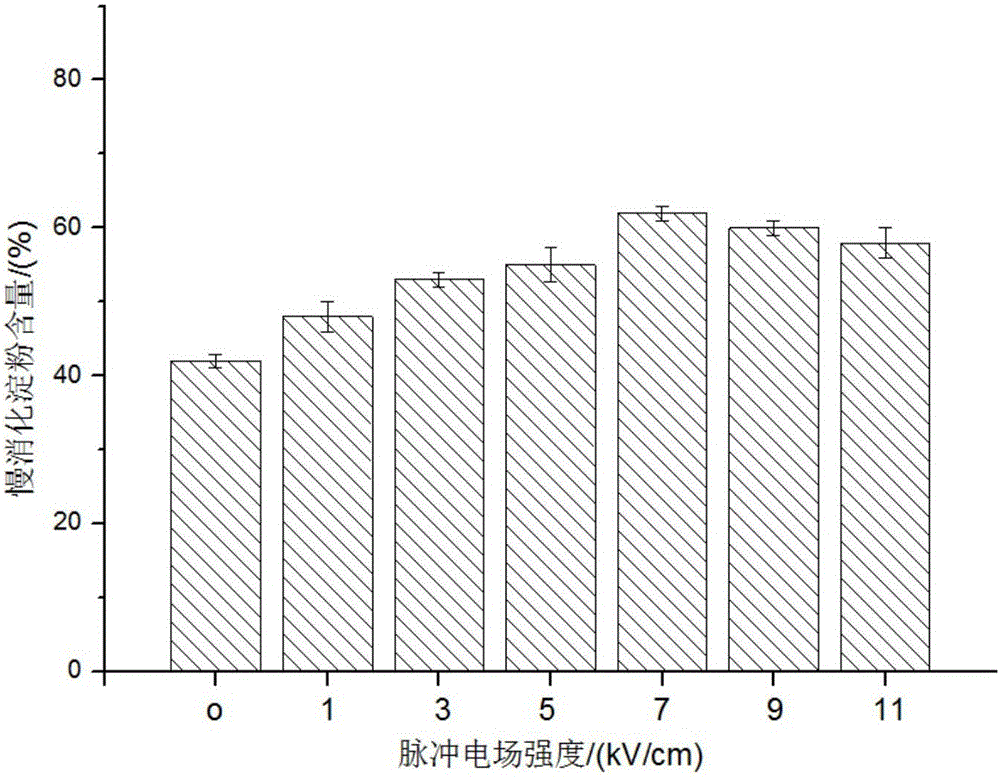

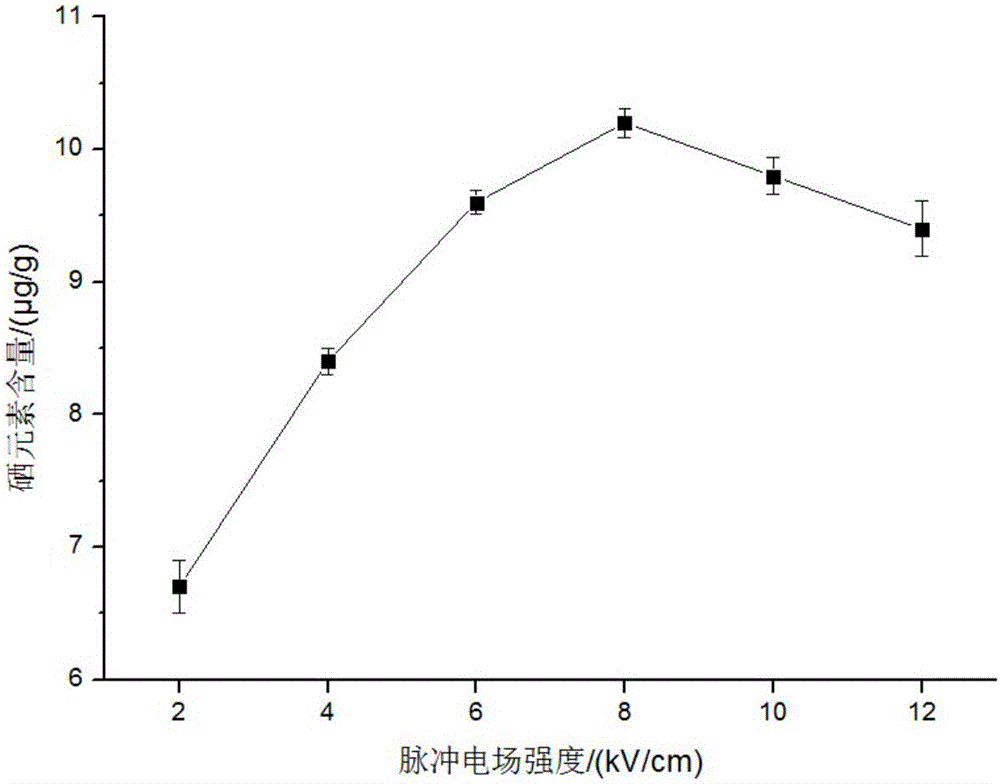

A pulsed electric field and nutritional rice paste technology, applied in the field of rice paste processing, can solve the problems of unusable starch selenium polysaccharides, high degree of esterification substitution, low utilization rate of human body, etc., to improve intake deficiency and promote interaction , the effect of increasing the content of selenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

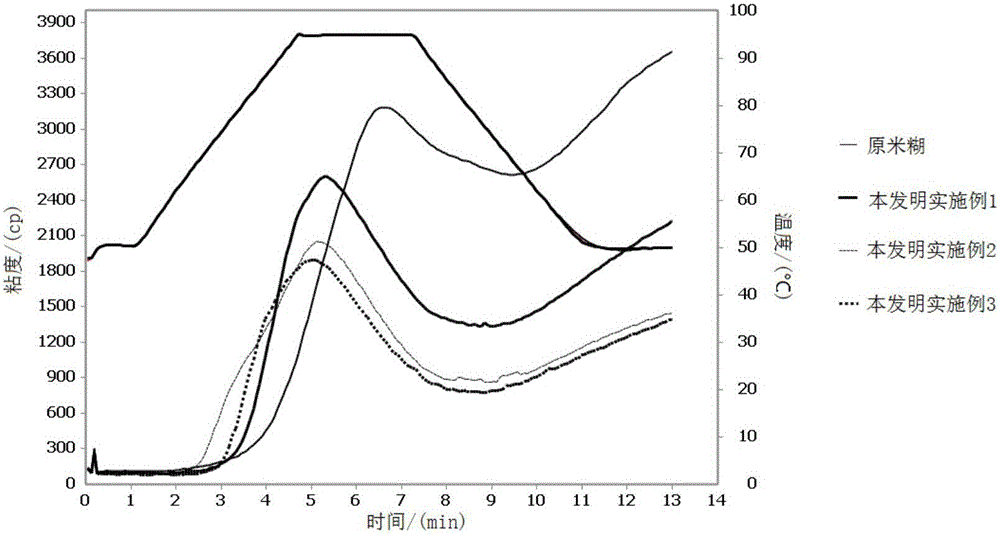

[0054] NaHSO 3 and NaNO 2 The solution (substance mass ratio is 1.0) mixes evenly, adds 30% polished rice emulsion, adjusts electrical conductivity to be 1.0mS / cm, and is placed in the treatment chamber of pulse electric field treatment device, guarantees the stable flow of processed emulsion, The parameters of the pulsed electric field were set as follows: the pulse width was 20 μs, the flow rate was 300 L / h, the pulse frequency was 1000 Hz, the electric field strength was 2 kV / cm, the pulsed electric field treatment time was 30 min, and starch sulfate was obtained after washing, drying and sieving. Add starch sulfate / selenite (w / w=1.5:5.0) to distilled water to configure a 30% (w / w) suspension, adjust the conductivity to 1.0mS / cm, and place it in the pulse processing device The processing is carried out in the processing chamber, the pulse width is 60 μs, and other pulse electric field parameters are the same as above. After washing, drying and sieving, the selenium-enriche...

Embodiment 2

[0056] NaHSO 3 and NaNO 2 The solution (substance mass ratio is 2.0) mixes evenly, adds 20% polished rice emulsion, adjusts electrical conductivity to be 3.0mS / cm, and is placed in the treatment chamber of pulse electric field treatment device, guarantees the stable flow of treated emulsion, The pulse electric field parameters are set as follows: pulse width is 80μs, flow rate is 500L / h, pulse frequency is 800Hz, electric field strength is 8kV / cm, pulse electric field treatment time is 30min, starch sulfate is obtained after washing, drying and sieving. Add starch sulfate / selenite (w / w=1:2.3) to distilled water to configure a 30% (w / w) suspension, and adjust the conductivity to 2.0mS / cm, place it in the pulse processing device The treatment is carried out in the treatment chamber, the electric field strength is 3kV / cm, and the other pulse electric field parameters are the same as above. After washing, drying and sieving, the selenium-enriched pregelatinized nutritional rice f...

Embodiment 3

[0058] NaHSO 3 and NaNO 2 The solution (substance mass ratio is 3.0) mixes evenly, adds 25% polished rice emulsion, adjusts electrical conductivity to be 2.5mS / cm, and is placed in the treatment chamber of pulse electric field treatment device, guarantees the stable flow of processed emulsion, The parameters of the pulsed electric field were set as follows: the pulse width was 60 μs, the flow rate was 400 L / h, the pulse frequency was 1500 Hz, the electric field strength was 6 kV / cm, the pulsed electric field treatment time was 50 min, and starch sulfate was obtained after washing, drying and sieving. Add starch sulfate / selenite (w / w=1.0:5.0) to distilled water to configure a 40% (w / w) suspension, and adjust the conductivity to 2.0mS / cm, place it in the pulse processing device The processing is carried out in the processing chamber, the pulse width is 80 μs, and other pulse electric field parameters are the same as above. After washing, drying and sieving, the selenium-enriche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com