Conductive ink and preparation method thereof

An ink, transparent and conductive technology, applied in inks, household appliances, applications, etc., can solve the problems of inability to pattern the transparent conductive layer coating process, inability to use screen printing, low light transmittance, etc., to improve the probability of overlapping , The effect of reducing surface roughness and high optical transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Prepare transparent conductive ink as follows:

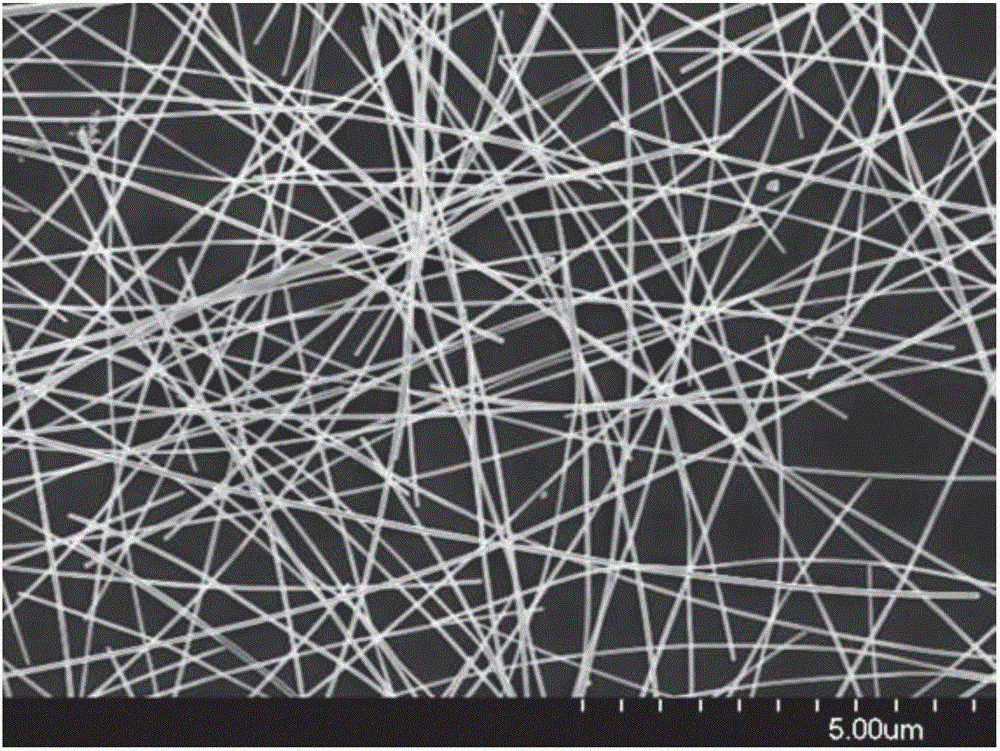

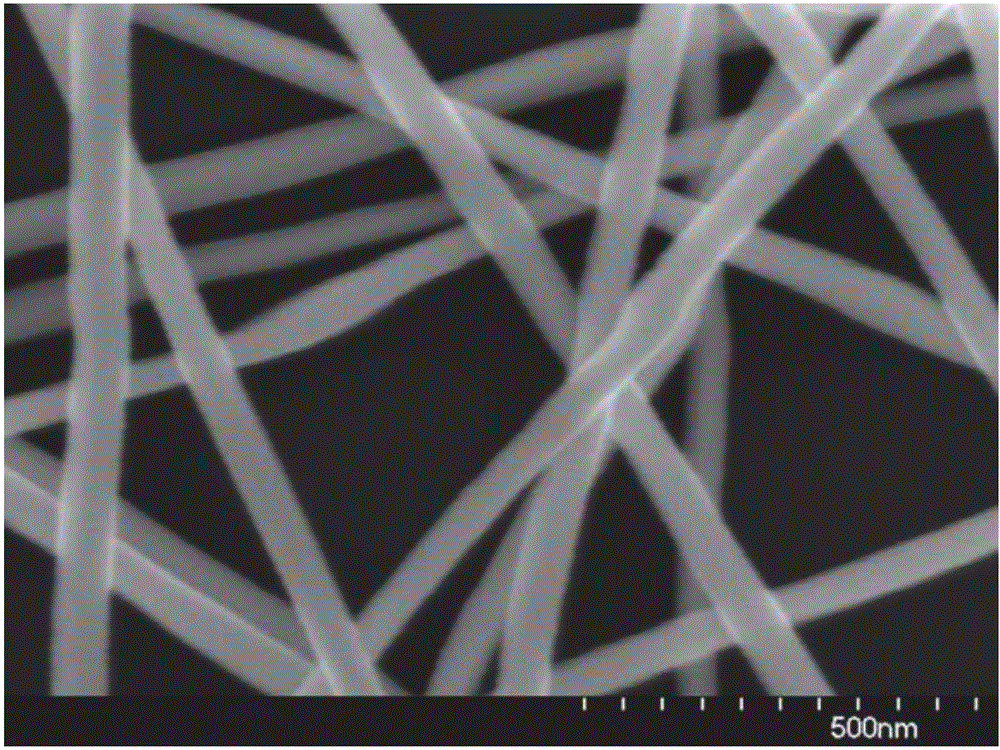

[0048] Get 250g PEDOT / PSS (Germany Heraeus PH1000) in 2000mL beaker, under the stirring of 500r / min, add the isopropanol solution of 250g nano-silver wire (wherein the concentration of nano-silver wire is 10mg / mL, average wire diameter is 40nm, The average line length is 40μm, the aspect ratio is 1000, figure 1 It is a 10,000-fold magnification of the scanning electron microscope of the nano-silver wire. figure 2 It is the 100,000-fold magnification of the scanning electron microscope of the silver nanowire), after dispersing for 10 minutes, add 50g of dimethyl sulfoxide, 20g of alkali-soluble thickener (Rohm and Haas ASE-60), and surfactant (Tego dispersers740w) in sequence 5g, leveling agent (Tego Glid410) 5g, water-based polyurethane 5g, continue to disperse for 10min, then add isopropanol: deionized water=1: 1 mixed solvent 415g, continue to disperse for 10min, then add 5g ammoniacal liquor, adjust the pH value at ...

Embodiment 2

[0052] Prepare transparent conductive ink as follows:

[0053] Get 350gPEDOT / PSS (Germany Heraeus PH1000) in 2000mL beaker, under the stirring of 500r / min, add the isopropanol solution of 150g nano-silver wire (wherein the concentration of nano-silver wire is 10mg / mL, the average wire diameter is 30nm, The average line length is 30 μm, the aspect ratio is 1000), after dispersing for 10 minutes, add 50 g of dimethyl sulfoxide, 20 g of hydroxypropyl methylcellulose, 5 g of surfactant (TRITONx100), and 5 g of leveling agent (Tego Glid410) , 5g of water-based acrylic resin, continue to disperse for 10min, then add 415g of mixed solvent of isopropanol: deionized water=1:1, continue to disperse for 10min, then add 4g of diethanolamine, adjust the pH value between 8 and 9, and ultrasonically vibrate 5min, after mixing evenly, a transparent conductive ink for screen printing was prepared.

[0054] Prepare transparent conductive film according to the following method:

[0055] Using ...

Embodiment 3

[0057] Prepare transparent conductive ink as follows:

[0058] Take 350g PEDOT / PSS (purchased from Shanghai Chunyuan Phytochemical Co., Ltd.) in a 2000mL beaker, add 150g nano-silver wire propylene glycol methyl ether solution under stirring at 500r / min (wherein the nano-silver wire concentration is 10mg / mL, the average wire Diameter is 30nm, average line length is 30μm, aspect ratio 1000), after dispersing for 10min, add dimethyl sulfoxide 50g, hydrophobically modified non-polyurethane thickener (L100 of Rockwood) 20g, surfactant ( BYK-151) 5g, leveling agent (TegoGlid410) 5g, water-based acrylic resin 5g, continue to disperse for 10min, then add ethylene glycol: deionized water = 1: 1 mixed solvent 415g, continue to disperse for 10min, then add 5g of triethanolamine , adjust the pH value between 8 and 9, ultrasonically oscillate for 5 minutes, and mix evenly to prepare a transparent conductive ink for silk screen printing.

[0059] Prepare transparent conductive film accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com