High-calorific-value environment-friendly fuel and preparation method thereof

A high calorific value, fuel technology, applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of matching, difficult molding, low utilization rate, etc., to achieve the effect of high fuel calorific value, improve quality, and reduce extrusion energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

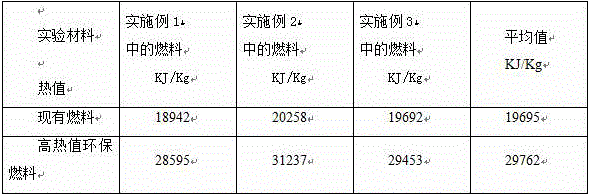

Examples

Embodiment 1

[0019] An environmentally friendly fuel with high calorific value, including the following raw materials in parts by weight: 20 parts of vine straw powder, 10 parts of rapeseed straw powder, 20 parts of hemp straw powder, 10 parts of sunflower straw powder, and 30 parts of biomass briquette fuel weeds , 1 part of turpentine, 1 part of ethylene glycol, 0.1 part of antioxidant 2,6 di-tert-butyl 4-methylphenol, 1 part of ferrocene additive, 1 part of biological enzyme additive catalase and biological lipase And 3 parts of auxiliary fatty alcohol polyoxyethylene ether.

[0020] A preparation method of high calorific value environment-friendly fuel, comprising the following steps:

[0021] 1) Take 20 parts of Manqing straw powder, 10 parts of rapeseed straw powder, 20 parts of hemp stalk powder, 10 parts of sunflower straw powder, and 30 parts of biomass briquette fuel weeds, mix them, and then put them in the pulverizer Carry out crushing treatment in the process, after the crush...

Embodiment 2

[0025] An environment-friendly fuel with high calorific value, comprising the following raw materials in parts by weight: 30 parts of vine straw powder, 20 parts of rapeseed straw powder, 30 parts of hemp straw powder, 20 parts of sunflower straw powder, and 40 parts of biomass briquette fuel rice husk , 3 parts of turpentine, 3 parts of ethylene glycol, 0.3 parts of antioxidant 2,6 di-tert-butyl 4-methylphenol, 1.5 parts of additive tert-butyl ferrocene, biological enzyme additive catalase and biological fat 2 parts of enzyme and 5 parts of auxiliary fatty alcohol polyoxyethylene ether.

[0026] A preparation method of high calorific value environment-friendly fuel, comprising the following steps:

[0027] 1) Take 30 parts of Manqing straw powder, 20 parts of rapeseed straw powder, 30 parts of hemp straw powder, 20 parts of sunflower straw powder, and 40 parts of biomass briquette fuel rice husk, mix them, and then put them in the pulverizer Carry out crushing treatment in t...

Embodiment 3

[0031] An environment-friendly fuel with high calorific value, comprising the following raw materials in parts by weight: 25 parts of vine straw powder, 15 parts of rapeseed straw powder, 25 parts of hemp straw powder, 15 parts of sunflower straw powder, and 35 parts of biomass briquette fuel sorghum straw , 2 parts of turpentine, 2 parts of ethylene glycol, 0.2 parts of antioxidant 2,6 di-tert-butyl 4-methylphenol, 1.2 parts of a mixture of additive ferrocene and tert-butyl ferrocene, biological enzyme additive 1.5 parts of catalase and biological lipase and 4 parts of auxiliary fatty alcohol polyoxyethylene ether.

[0032] A preparation method of high calorific value environment-friendly fuel, comprising the following steps:

[0033] 1) Take 25 parts of vine straw powder, 15 parts of rapeseed straw powder, 25 parts of hemp stalk powder, 15 parts of sunflower straw powder, and 35 parts of biomass briquette fuel sorghum straw, and then put them in the pulverizer Carry out cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com