A thin film used for thermoelectric power generation devices under strong irradiation environment and its preparation method

A technology of thermoelectric power generation and strong irradiation, which is applied in the manufacture/processing of thermoelectric devices, materials for lead-out wires of thermoelectric devices, vacuum evaporation coating, etc., can solve the problems of no relevant introduction of thin films, and achieve low cost and high efficiency High and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The concrete preparation method of this thin film comprises the following steps:

[0030] (1) Take high-purity metal uranium flakes, pretreat the metal uranium flakes, and nitride the treated metal uranium to make uranium nitrogen oxides on the surface of the metal uranium flakes;

[0031] (2) Magnetron sputtering deposition of uranium nitride oxide produced on the surface of metal uranium flakes onto the substrate surface of an electrical insulator, thereby obtaining uranium nitride thermoelectric materials, and then making uranium nitride thermoelectric materials into thin films.

Embodiment 1

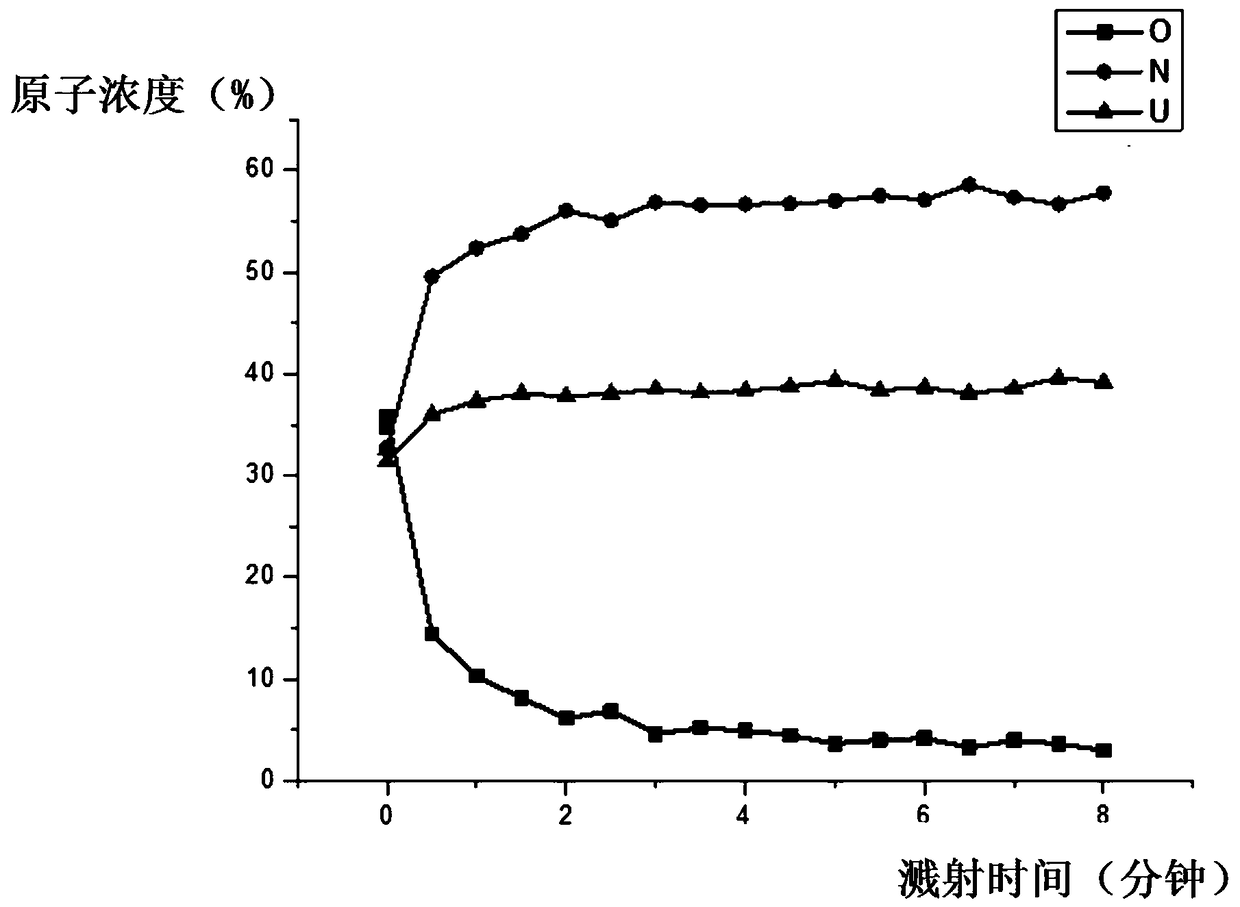

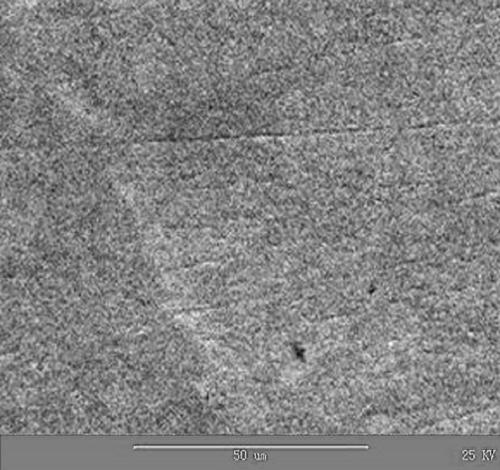

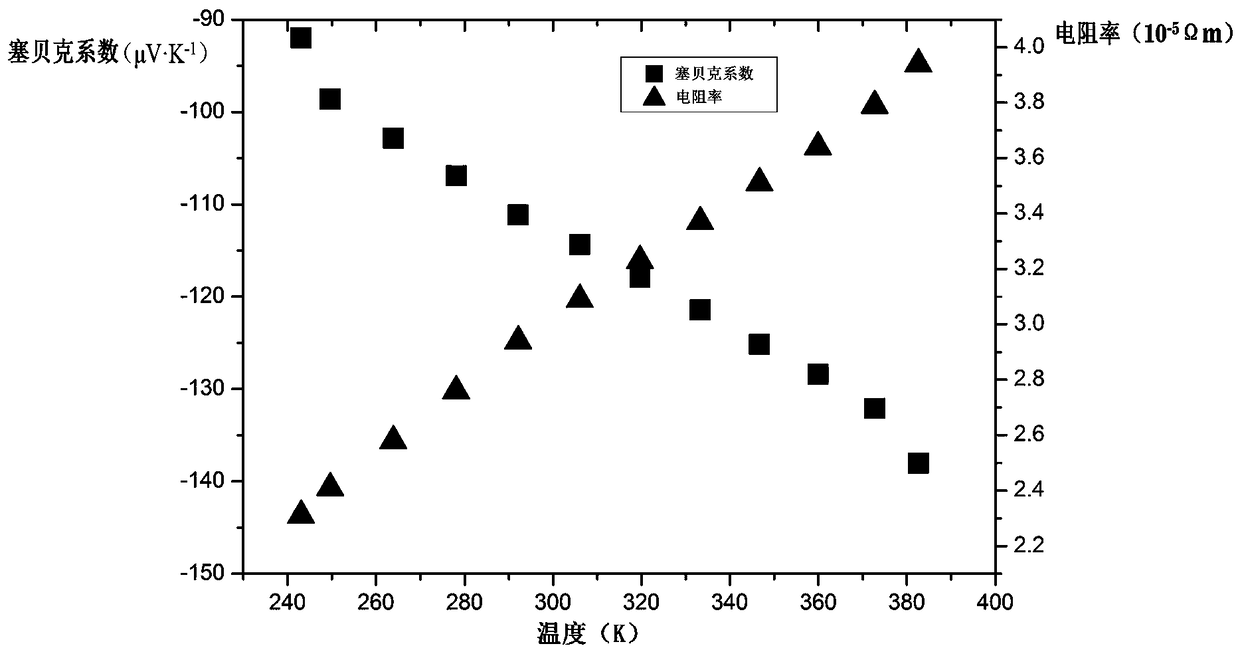

[0033] In this embodiment, it is further preferred to use the main chemical composition as U 2 N 3 o x The thermoelectric material is used as the main material of the film. The physical properties of the thermoelectric material, such as figure 1 , figure 2 , image 3 As shown, it has a large thermoelectric coefficient (92~138 μV / K) in the temperature range of 243~383 K, and has a very low resistivity in this temperature range (2.31×10-5Ωm ~3.94×10-5Ωm ), its power factor reaches up to 4.83 μWcm-1K-2 at 383 K, which is higher than that of uranium-oxygen system and uranium-boron system, and its performance is comparable to that of mature oxide thermoelectric materials. Therefore by U 2 N 3 o x Thin films made of thermoelectric materials also have these properties, and can realize functions such as cooling and thermoelectric power generation in a special radiation-resistant environment, and are used for thermoelectric power generation devices in strong radiation environm...

Embodiment 2

[0035] The present embodiment provides the concrete steps of preparing this thin film, as follows:

[0036] 1) Mechanically grind high-purity metal uranium flakes to No. 2000 sandpaper, then polish them with 0.1 μm diamond polishing paste, wash them with alcohol, acetone, and deionized water several times, then dry them with a hair dryer, and quickly transfer them to in a vacuum chamber with a vacuum of 10 -4 Pa above, followed by 50Pa high-purity nitrogen with a purity of 99.999%. Add -800V pulse high voltage between the high-purity metal uranium sheet and the vacuum chamber, its frequency is 50 kHz, and the duty cycle is 30%, thereby forming a glow discharge, and the ionized nitrogen plasma and the high-purity metal uranium sheet The surface reacts. At the same time as the above process, heat the high-purity metal uranium flake sample at 400°C for 90 minutes to accelerate the diffusion reaction of nitrogen on the surface of the high-purity metal uranium flake, realize the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com