Negative pole material of lithium iron phosphate power battery and preparation method of negative pole material

A power battery, lithium iron phosphate technology, applied in the direction of battery electrodes, batteries, secondary batteries, etc., can solve the problems of low high-current charge and discharge capacity, low first-time cycle efficiency, and monitoring battery capacity, etc., to achieve good over-discharge performance, Effects of improving cycle performance and rate performance, and preventing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

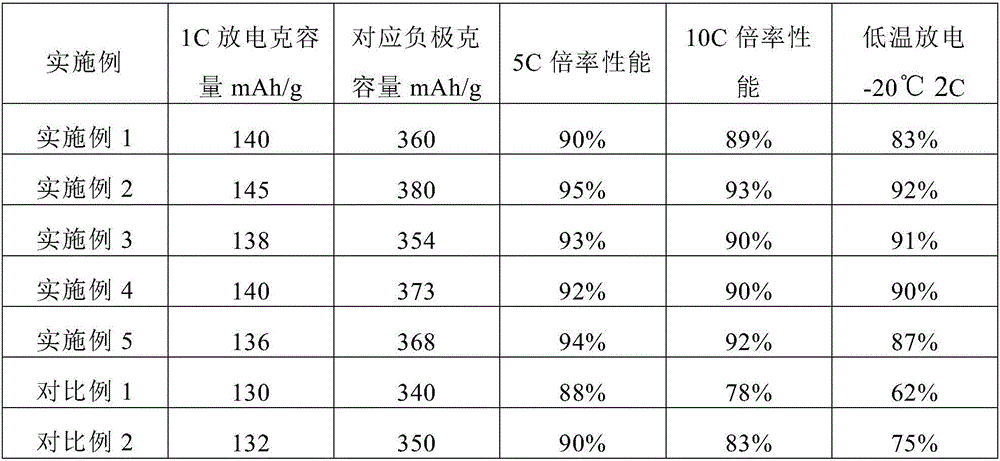

Embodiment 1

[0036]The petroleum coke is crushed and sieved, and the particles with a particle size between 20 mesh and 30 mesh are screened out, and then the particles with a mass ratio of 15:1 are mixed with asphalt and then granulated to obtain a particle size of 10mm-50mm Petroleum coke regranulated; then the petroleum coke regranulated was heat-treated at 600°C in the atmosphere for 1 hour to obtain calcined petroleum coke; The heating rate of ℃ / min is raised to 2600 ℃ and kept for 1 hour to obtain graphitized petroleum coke; finally, according to the mass ratio of graphitized petroleum coke and glucose of 10:1, graphitized petroleum coke is added to 0.5mol / L glucose solution and mixed evenly , and react at a temperature of 150°C for 5 hours to obtain the negative electrode material of lithium iron phosphate power battery. The prepared negative electrode material of lithium iron phosphate power battery has a core-shell structure with petroleum coke as the core and carbon as the shell, ...

Embodiment 2

[0039] The petroleum coke is crushed and sieved, and the particles with a particle size between 30 mesh and 40 mesh are screened out, and then the particles with a mass ratio of 20:1 are mixed with asphalt and then granulated to obtain a particle size of 30mm-80mm Petroleum coke re-granulation; then the petroleum coke re-granulation was heat-treated at 700°C in the atmosphere for 2 hours to obtain calcined petroleum coke; then the calcined petroleum coke was cooled and heated in a nitrogen atmosphere at a flow rate of 100ml / min for 10 The heating rate of °C / min was raised to 2300 °C and kept for 2 hours to obtain graphitized petroleum coke; finally, according to the mass ratio of graphitized petroleum coke and glucose of 20:1, graphitized petroleum coke was added to 1mol / L glucose solution and mixed evenly. And react at a temperature of 200°C for 8 hours to obtain the negative electrode material of lithium iron phosphate power battery. The prepared negative electrode material o...

Embodiment 3

[0042] The petroleum coke is crushed and sieved, and the particles with a particle size between 40 mesh and 50 mesh are screened out, and then the particles with a mass ratio of 20:1 are mixed with asphalt and then granulated to obtain a particle size of 50mm-100mm Petroleum coke re-granulation; then the petroleum coke re-granulation was heat-treated in the atmosphere at 800°C for 3 hours to obtain calcined petroleum coke; then the calcined petroleum coke was cooled and heated in a nitrogen atmosphere at a flow rate of 150ml / min for 12 The heating rate of °C / min was raised to 2000 °C and kept for 3 hours to obtain graphitized petroleum coke; finally, according to the mass ratio of graphitized petroleum coke and glucose of 30:1, graphitized petroleum coke was added to 3mol / L glucose solution and mixed evenly. And react at a temperature of 200°C for 10 hours to obtain the negative electrode material of lithium iron phosphate power battery. The prepared negative electrode material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com