Calcium-silicon mixed scale removing agent for alkali-surfactant-polymer mechanical recovery well

A calcium-silicon and scale-removing technology, which is used in cleaning appliances, earth-moving drilling, wellbore/well components, etc., can solve the problems of insufficient scale-cleaning rate, equipment corrosion, secondary precipitation, etc., and prolong the scale-cleaning time. , reduce corrosion, reduce the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

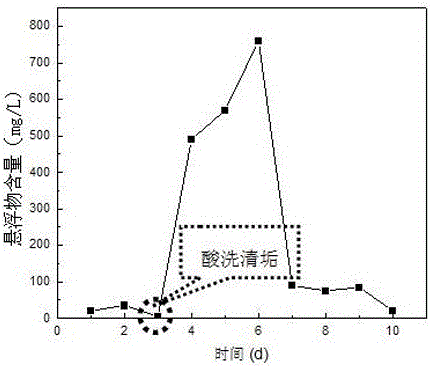

[0038] This three-way flooding well calcium-silicon mixed scale cleaning agent is composed of carboxyethyl thiosuccinic acid, ammonium hydrogen fluoride, benzyl quinoline chloride, sodium diisobutylnaphthalene sulfonate, and water, according to mass percentage Calculated, carboxyethyl thiosuccinic acid 9%, ammonium bifluoride 9%, benzyl quinoline chloride 0.9%, sodium diisobutylnaphthalene sulfonate 2‰, and the rest is water; Calcium-silicon mixed scale cleaning agent does not generate secondary precipitation during the cleaning process, and the corrosion rate is 0.43g / ( m 2 h).

[0039] In this embodiment, the calcium-silicon mixed scale cleaning agent in the mining well of the three-way flooding machine is used to remove the calcium-silicon mixed scale method mainly composed of crystalline calcium carbonate and amorphous silicon dioxide. Figure 6 :

[0040] (1) put 6m 3 The calcium-silicon mixed scale descaling agent for the production well of the three-way flooding mach...

Embodiment 2

[0045] This three-way flooding well calcium-silicon mixed scale cleaning agent is composed of carboxyethyl thiosuccinic acid, ammonium hydrogen fluoride, benzyl quinoline chloride, sodium diisobutylnaphthalene sulfonate, and water, according to mass percentage In total, 13% of carboxyethylthiosuccinic acid, 9% of ammonium bifluoride, 1.3% of benzyl quinoline chloride, 5‰ of sodium diisobutylnaphthalene sulfonate, and the rest is water; Calcium-silicon mixed scale cleaning agent does not generate secondary precipitation during the cleaning process, and the corrosion rate is 0.43g / ( m 2 h).

[0046] In this embodiment, the calcium-silicon mixed scale cleaning agent in the production well of the three-way flooding machine is used to remove the calcium-silicon mixed scale mainly composed of crystalline calcium carbonate and amorphous silicon dioxide. The method is the same as in Example 1.

Embodiment 3

[0048] This three-way flooding well calcium-silicon mixed scale cleaning agent is composed of carboxyethyl thiosuccinic acid, ammonium hydrogen fluoride, benzyl quinoline chloride, sodium diisobutylnaphthalene sulfonate, and water, according to mass percentage In total, 11% of carboxyethylthiosuccinic acid, 7% of ammonium bifluoride, 1.1% of benzyl quinoline chloride, 5‰ of sodium diisobutylnaphthalenesulfonate, and the rest is water; Calcium-silicon mixed scale cleaning agent does not generate secondary precipitation during the cleaning process, and the corrosion rate is 0.43g / ( m 2 h).

[0049] In this embodiment, the calcium-silicon mixed scale cleaning agent in the production well of the three-way flooding machine is used to remove the calcium-silicon mixed scale mainly composed of crystalline calcium carbonate and amorphous silicon dioxide. The method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com