Polarization white light LED based on fluorescent ceramic and double-layer nanometer grating structure

A fluorescent ceramic and nano-grating technology, applied in nano-optics, nano-technology, nano-technology and other directions, can solve the problems of difficult realization, low polarization degree of polarized white light, difficult material growth, etc., and achieve good TM wave transmittance and high polarization. The effect of adjustable light transmittance and size parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

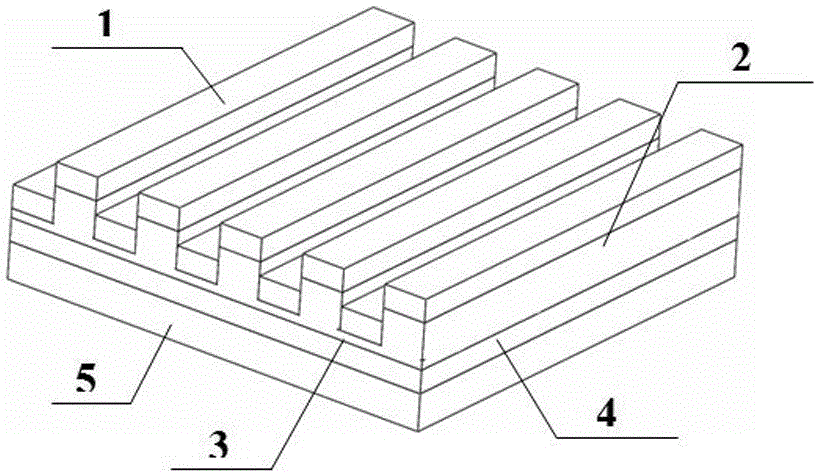

[0046] Embodiment one: see attached figure 1 As shown, the GaN-based polarized white light LED based on fluorescent ceramics and a double-layer nano-grating structure includes 1. a metal layer; 2. a dielectric grating layer; 3. a transition layer; 4. a fluorescent ceramic substrate; 5. a blue LED. GaN-based blue LED emits blue light through the double-layer nano-metal grating based on fluorescent ceramics, and emits polarized white light, which is a GaN-based polarized white LED based on fluorescent ceramics and double-layer nano-grating structure.

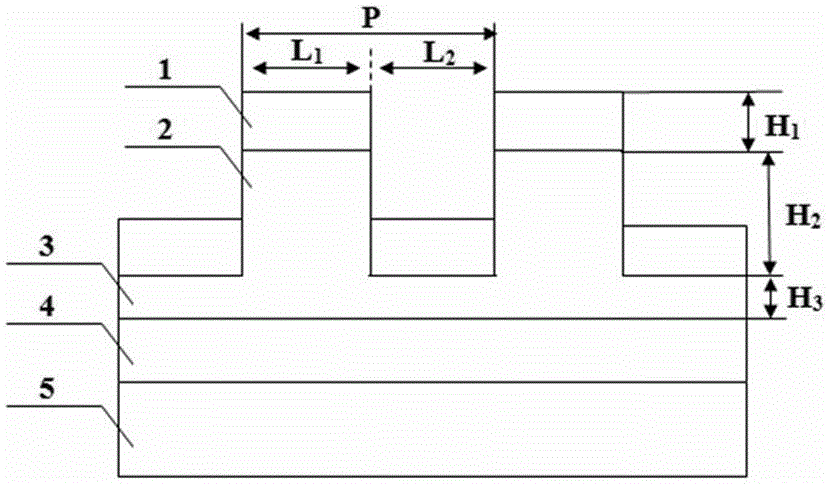

[0047] See attached figure 2 , Schematic diagram of the front view structure of GaN-based white light LED based on fluorescent ceramics and double-layer nano-grating structure; where: dielectric grating layer period P=150nm; duty cycle DC= L1 / P=0.5; metal layer height H1=50nm; dielectric grating Height H2=80nm; transition layer thickness H3=20nm. The above-mentioned double-layer nano-grating structure is based on a fluorescent ...

Embodiment 2

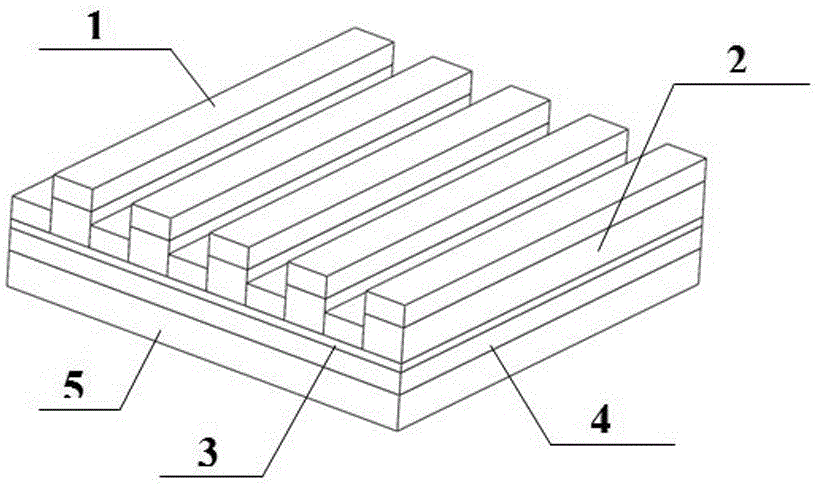

[0057] See attached image 3, GaN-based polarized white light LED based on fluorescent ceramics and double-layer nano-grating structure, including 1. metal layer; 2. dielectric grating layer; 3. transition layer; 4. fluorescent ceramic substrate; 5. blue LED; where: dielectric grating layer Period P=150nm; duty cycle DC= L1 / P=0.5; metal layer height H1=50nm; dielectric grating (silicon dioxide) height H2=80nm; transition layer (magnesium fluoride) thickness H3=20nm. The above-mentioned double-layer nano-grating structure is based on a fluorescent ceramic substrate and is coupled with a GaN-based blue LED structure to realize a white LED device.

[0058] A method for manufacturing a GaN-based polarized white light LED based on fluorescent ceramics and a double-layer nano-grating structure, comprising the following steps:

[0059] (1) Clean the fluorescent ceramics to remove the dirt and oil on the surface so that the surface of the fluorescent ceramics has better cleanliness a...

Embodiment 3

[0068] The parameters of the GaN-based polarized white light LED based on fluorescent ceramics and a double-layer nano-grating structure are consistent with those in Embodiment 1, and the manufacturing method includes the following steps:

[0069] (1) Clean the fluorescent ceramics to remove the dirt and oil on the surface so that the surface of the fluorescent ceramics has better cleanliness and adhesion;

[0070] (2) Coating a magnesium fluoride dielectric layer with a thickness of 100nm on the fluorescent ceramics by ion beam sputtering deposition;

[0071] (3) Apply a layer of embossing glue by spin coating method;

[0072] (4) Using UV-curable nano-imprinting technology to engrave the nano-grating photoresist structure;

[0073] (5) Use the ion reaction glue remover to remove the residual photoresist to obtain the nano-grating of the embossed glue medium;

[0074] (6) Etching by ion beam (IBE) process, and then removing residual photoresist to obtain dielectric nano-gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com