Sodium phenylbutyrate tablet and preparation method thereof

A technology of sodium phenylbutyrate and tablet, applied in the field of sodium phenylbutyrate tablet and preparation thereof, can solve the problems of inaccurate dosage, inability to take, unfavorable patient tolerance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, the preparation of sodium phenylbutyrate tablet (500mg specification)

[0028] The formulations for the 500 mg strength tablets are shown in Table 1.

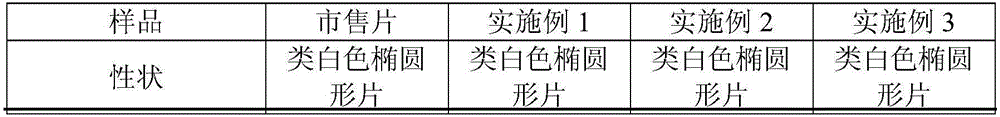

[0029] Table 1 Prescription of 500mg sodium phenylbutyrate tablet

[0030] components

unit (g)

Sodium phenylbutyrate

100

45.0

15.0

HPMC-K4M

8

10% ethanol in water

Appropriate amount

silica

2.0

Sheet weight

0.85

[0031] 1) Pulverize the original and auxiliary materials respectively, and pass through an 80-mesh sieve for subsequent use;

[0032] 2) Weigh sodium phenylbutyrate, microcrystalline cellulose, lactose, and hypromellose-K4M respectively according to the prescription amount, and mix evenly;

[0033] 3) Add an appropriate amount of 10% ethanol aqueous solution (volume concentration) to make a soft material, granulate with a 20-mesh sieve, dry at 60°C for about 2 hours, and gra...

Embodiment 2

[0037] Embodiment 2, the preparation of sodium phenylbutyrate tablet (500mg specification)

[0038] The formulations for the 500 mg strength tablets are shown in Table 2.

[0039] Table 2 Prescription of 500mg sodium phenylbutyrate tablet

[0040] components

unit (g)

Sodium phenylbutyrate

100

48.0

16

silica

0.75

1

pvp K30 (10% ethanol solution)

30

Sheet weight

0.83

[0041] 1) Pass the original and auxiliary materials through an 80-mesh sieve for subsequent use;

[0042] 2) prepare 30% ethanol aqueous solution (volume concentration), prepare 10wt% PVP with it K30 An appropriate amount of the solution is used as an adhesive for standby;

[0043] 3) Weigh sodium phenylbutyrate, microcrystalline cellulose and lactose according to the prescription quantity, mix well, add appropriate amount of binder to make soft material, granulate with...

Embodiment 3

[0047] Embodiment 3, the preparation of sodium phenylbutyrate tablet (500mg specification)

[0048] The formulations for the 500 mg strength tablets are shown in Table 3.

[0049] Table 3 Prescription of 500mg sodium phenylbutyrate tablet

[0050] components

unit (g)

Sodium phenylbutyrate

100

44.0

HPMC-K4M

4.4

0.75

silica

0.75

pvp K30 (10% ethanol solution)

25

Sheet weight

0.75

[0051] 1) Pass the original and auxiliary materials through an 80-mesh sieve for subsequent use;

[0052] 2) prepare 30% ethanol solution (volume concentration), prepare 10wt% PVP with it K30 An appropriate amount of solution is used as an adhesive for standby;

[0053] 3) Weigh sodium phenylbutyrate, microcrystalline cellulose and hypromellose-K4M respectively according to the prescription amount, mix them evenly, add an appropriate amount of binder to make soft m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com