Antioxidant nutrition preparation and preparation method thereof

A nutritional preparation, anti-oxidation technology, applied in the direction of anti-toxic agents, medical preparations containing active ingredients, pharmaceutical formulas, etc. The effect of oxidation, good product stability and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

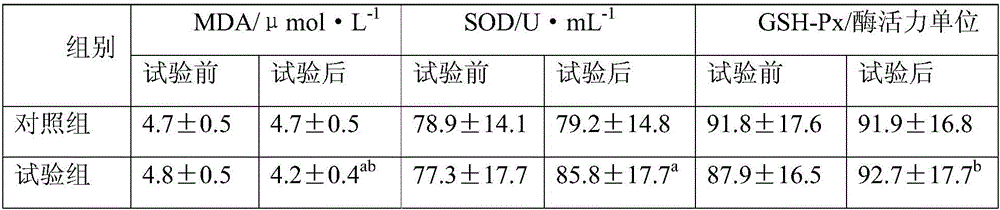

Image

Examples

Embodiment 1

[0024] A production process of an antioxidant nutritional preparation consists of the following steps:

[0025] 1. Weighing and initial mixing: Weigh 20kg of isomalt, 10kg of grape seed extract, 7kg of green tea extract, 1kg of lycopene, 0.8kg of lutein, and Haematococcus pluvialis extract according to parts by weight 4kg, 3.8kg of organic selenium, 5kg of microcrystalline cellulose, and 5kg of silicon dioxide were put into the mixer successively and mixed for 20 minutes, and passed through a 60-mesh sieve;

[0026] 2. Granulation: Put the initial mixed powder into a high-efficiency wet granulator, and use sodium carboxymethyl cellulose solution as a binder to granulate (wherein sodium carboxymethyl cellulose solution in sodium carboxymethyl cellulose: absolute ethanol : Water is 1:20:10, first dissolving sodium carboxymethyl cellulose in water, adding absolute ethanol after completely dissolving in water), wet granules are transferred to boiling dryer for drying after shaking...

Embodiment 2

[0030] A production process of an antioxidant nutritional preparation consists of the following steps:

[0031] 1. Weighing and initial mixing: Weigh 30kg of isomalt, 20kg of grape seed extract, 5kg of green tea extract, 0.5kg of lycopene, 0.5kg of lutein, and extract of Haematococcus pluvialis by weight. Compound 5kg, organic selenium 2kg, microcrystalline cellulose 7kg, silicon dioxide 7kg, drop into mixer successively and mix for 20 minutes, cross 60 mesh sieves;

[0032] 2. Granulation: Put the initial mixed powder into a high-efficiency wet granulator, and use sodium carboxymethyl cellulose solution as a binder to granulate (wherein sodium carboxymethyl cellulose solution in sodium carboxymethyl cellulose: absolute ethanol : Water is 1:20:10, first dissolving sodium carboxymethyl cellulose in water, adding absolute ethanol after completely dissolving in water), wet granules are transferred to boiling dryer for drying after shaking granulator, dry The granules are sized b...

Embodiment 3

[0036] A production process of an antioxidant nutritional preparation consists of the following steps:

[0037] 1. Weighing and primary mixing: Weigh 40kg of isomalt, 5kg of grape seed extract, 10kg of green tea extract, 2kg of lycopene, 1kg of lutein, and 5kg of Haematococcus pluvialis extract by weight , 8 kg of organic selenium, 15 kg of microcrystalline cellulose, and 10 kg of silicon dioxide were put into the mixer successively and mixed for 20 minutes, and passed through a 60-mesh sieve;

[0038] 2. Granulation: Put the initial mixed powder into a high-efficiency wet granulator, and use sodium carboxymethyl cellulose solution as a binder to granulate (wherein sodium carboxymethyl cellulose solution in sodium carboxymethyl cellulose: absolute ethanol : Water is 1:20:10, first dissolving sodium carboxymethyl cellulose in water, adding absolute ethanol after completely dissolving in water), wet granules are transferred to boiling dryer for drying after shaking granulator, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com