A fresh milk processing system

A processing system and fresh milk technology, applied in liquid treatment, transportation, packaging, packaging, etc., can solve the problems of incomplete killing of milk pathogenic bacteria and spores, slow down the speed of bacterial reproduction, and reduce milk nutrients, etc., to achieve extended Preserve effects, increase interactions, and increase molecular binding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

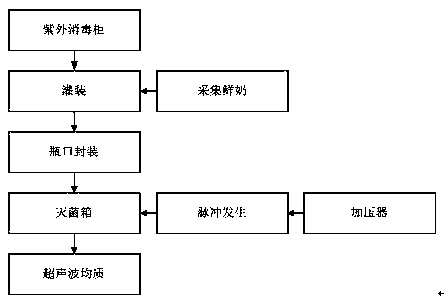

[0031] Such as figure 1 Shown, a kind of fresh milk processing system comprises the ultraviolet sterilizing cabinet connected in sequence, fresh milk filling machine, bottle cap sealing machine, sterilizing box and ultrasonic homogenizer, described fresh milk filling machine and fresh collected fresh The milk is directly connected, and a pulse generating electric field is arranged around the sterilization box, and a water flow pressurizer is arranged outside the pulse generating electric field, and the water flow pressurizer is connected with a water jet device, and the water jet device can spray water through the The electric field generated by the pulse enters the sterilization box, and a number of filling bottles are arranged in the ultraviolet disinfection box. The ambient temperature in the sterilization box is kept constant at 2-3°C, and the fresh milk processing system is placed in a sterile environment. The front end of the ultraviolet disinfection cabinet is connecte...

Embodiment 2

[0033] A method for processing fresh milk with a fresh milk processing system:

[0034] Step 1, first place the filling bottle used for filling fresh milk in the soaking pool, soak for 10-15 minutes, rinse with clean water, put the bottle cap and bottle body in the ultraviolet disinfection cabinet, and put them under the UV light. Vertical radiation disinfection is carried out at a distance of 1m below, and the radiation time is 32 minutes;

[0035] Step 2: Cool the collected fresh milk to 2~3°C, and fill it into the bottle through the filling machine;

[0036] Step 3: Seal the body and cap of the filled bottle with a bottle-top sealing machine;

[0037] Step 4, enter the sterilization box, generate pulses through the pulse generating electric field, pass the water flow through the high-pressure pressurizer, pressurize the water flow to 120MPa, and spray out several high-pressure water flows. The injection speed of the high-pressure water flow is 170m / s. The high-pressure wa...

Embodiment 3

[0040] The filling bottle consists of 17 parts by mass of polycarbonate, 8 parts of polylactic acid, 24 parts of chitosan, and 12 parts of magnetic Fe 3 o 4 / Ag nanoparticles made of 5 parts carboxymethyl chitosan and 31 parts polyethylene terephthalate. Magnetic Fe 3 o 4 The average particle size of the / Ag nanoparticles was 14 nm. A light-shielding layer is provided in the middle of the filling bottle, and the thickness of the light-shielding layer is 20 μm. The light-shielding layer consists of 7 parts by mass of simethicone, 3 parts of zinc stearate, 37 parts of carbon black, 12 parts of trimethylolpropane triacrylate, 21 parts of nano titanium dioxide, and 9 parts of crotonate graft chitosan Sugar, 17 parts polycarbonate, 8 parts polylactic acid, 31 parts polyethylene terephthalate, and 14 parts carbon fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com