Preparation method of high-temperature oxidation resistant thermal barrier coating on Cf/SiC composite surface

A high-temperature anti-oxidation and thermal barrier coating technology, applied in the field of composite materials, can solve the problems of complex process, high temperature resistance of the coating and poor performance of oxygen permeation and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a C f A preparation method of a high temperature anti-oxidation thermal barrier coating on the surface of a / SiC composite material, the method comprising:

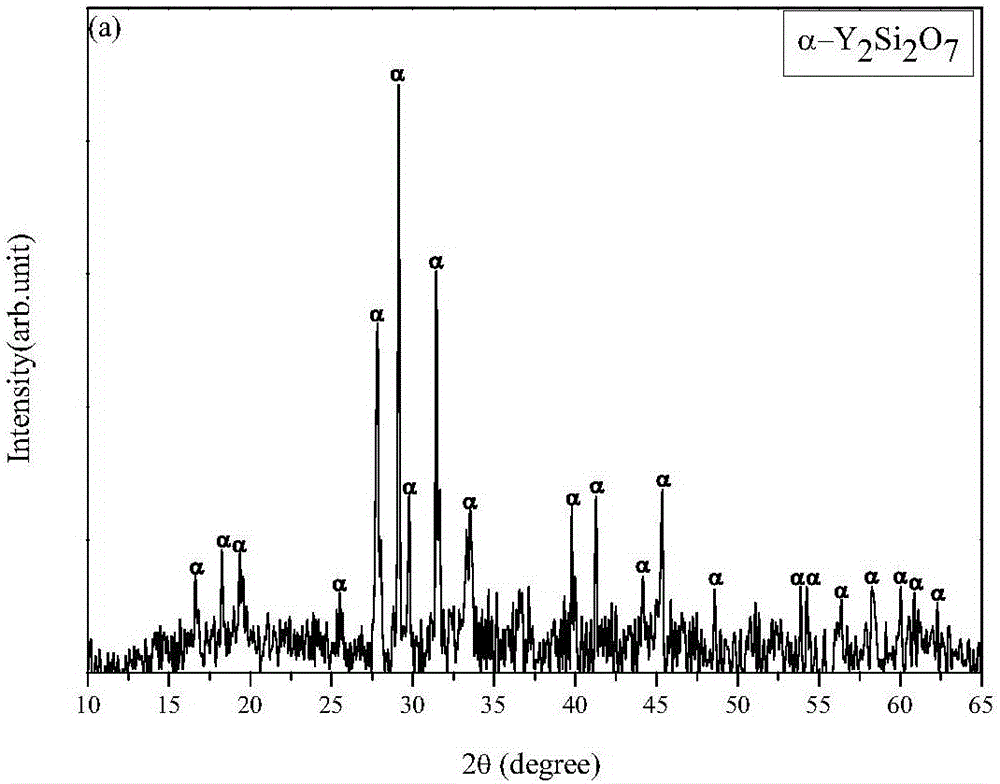

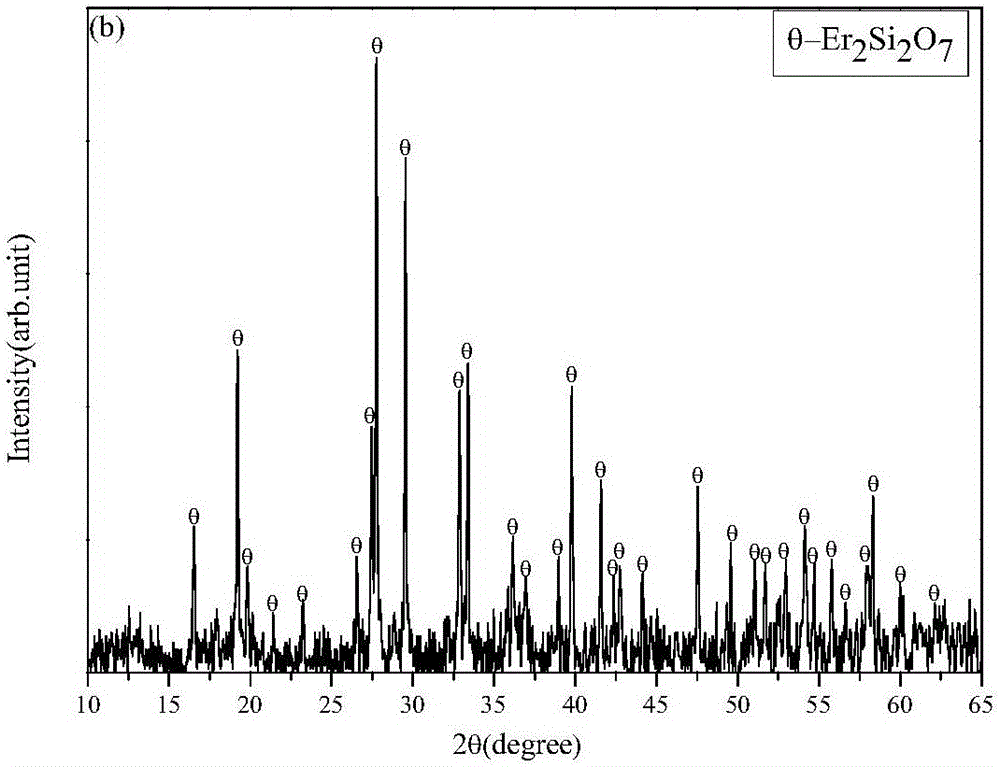

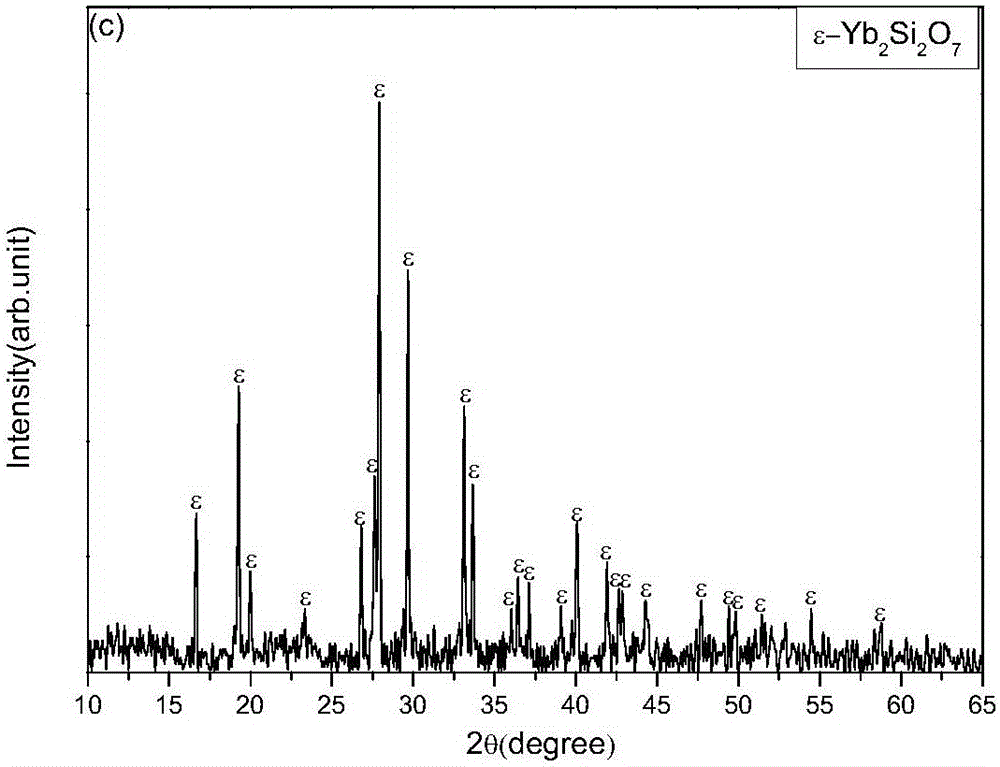

[0031] Step 1: Prepare Re separately 2 Si 2 O 7 Powder and LaMgAl 11 O 19 powder, Re is a rare earth element, selected from one of Y, Er or Yb;

[0032] Step 2: Convert the Re obtained in Step 1 2 Si 2 O 7 Powder and LaMgAl 11 O 19 The powders were mixed with deionized water, ammonium citrate, and gum arabic, respectively, to obtain Re 2 Si 2 O 7 Slurry and LaMgAl 11 O 19 slurry, the Re 2 Si 2 O 7 Slurry and LaMgAl 11 O 19 The slurry was ball milled, screened and granulated, respectively, to obtain Re 2 Si 2 O 7 Spray powder and LaMgAl 11 O 19 spray powder;

[0033] Step 3: Put C f / SiC matrix is pretreated to obtain pretreated C f / SiC matrix;

[0034] Step 4: The coating is prepared by APS technology, and the Re obtained in the above step 2 is 2 Si 2 ...

Embodiment 1

[0046] Take yttrium oxide (Y 2 O 3 ) powder and silicon dioxide (SiO 2 ) powder mix, take La in a molar ratio of 1:11:2 2 O 3 powder, Al 2 O 3 Powder and MgO powder are mixed. Deionized water and zirconia pellets were added to the two mixed powders, followed by rolling ball milling for 8 hours. After ball milling, the pellets were taken out, and the slurry was dried in an oven at 100 °C. The powder obtained after drying was subjected to rapid centrifugal ball milling for 10 minutes. Pass through a 60 μm sieve. The resulting mixed Y 2 O 3 and SiO 2The raw material powder is subjected to solid-phase reaction at a high temperature of 1400 ° C for 6 hours to synthesize high-purity Y 2 Si 2 O 7 Powder; mix the resulting La 2 O 3 , Al 2 O 3 The high-purity LaMgAl was synthesized by solid-phase reaction with MgO raw material powder at a high temperature of 1550 °C for 6 hours. 11 O 19 powder.

[0047] Y prepared above 2 Si 2 O 7 Powder and LaMgAl 11 O 19 The p...

Embodiment 2

[0056] Take erbium oxide (Er 2 O 3 ) powder and silicon dioxide (SiO 2 ) powder mix; take La in a molar ratio of 1:11:2 2 O 3 powder, Al 2 O 3 The powder and MgO powder were mixed; both mixed powders were added with deionized water and zirconia pellets, and then ball milled for 10 hours. Perform rapid centrifugal ball milling for 15 min and pass through a 60 μm sieve. The obtained preparation Er 2 Si 2 O 7 The raw material powder was subjected to solid-phase reaction at a high temperature of 1425 ° C for 6.5 h; the obtained LaMgAl was prepared 11 O 19 The raw material powder was subjected to solid-phase reaction at a high temperature of 1575 °C for 6.5 h.

[0057] The Er obtained above was 2 Si 2 O 7 Powder and LaMgAl 11 O 19 The powders were mixed according to the mass ratio: powder: deionized water: ammonium citrate: gum arabic = 100:110:0.6:1, ball-milled for 50 hours, and then passed through a 120 μm sieve; the sieved slurry was heated at 105 °C Spray gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com