Bitterness-free shrimp-type low-molecular-weight peptides as well as preparation method and application thereof

A low-molecular-weight peptide, no bitterness technology, applied in the field of shrimp low-molecular-weight peptides and their preparation, can solve the problems that the enzymatic hydrolysis degree of low-molecular-weight peptides is difficult to control, the yield of specific products is low, and the production cost is high, and the bitterness removal effect is good. , The effect of saving separation and purification costs and saving energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

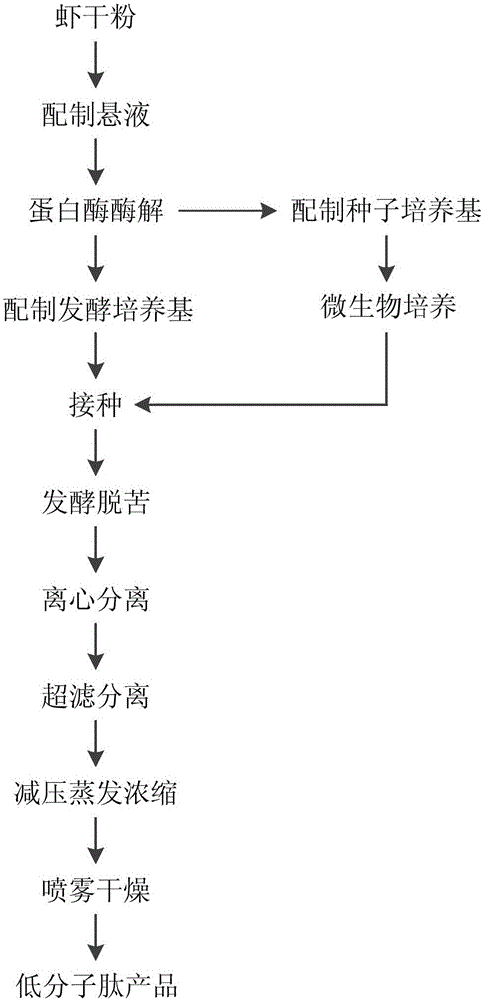

Method used

Image

Examples

Embodiment 1

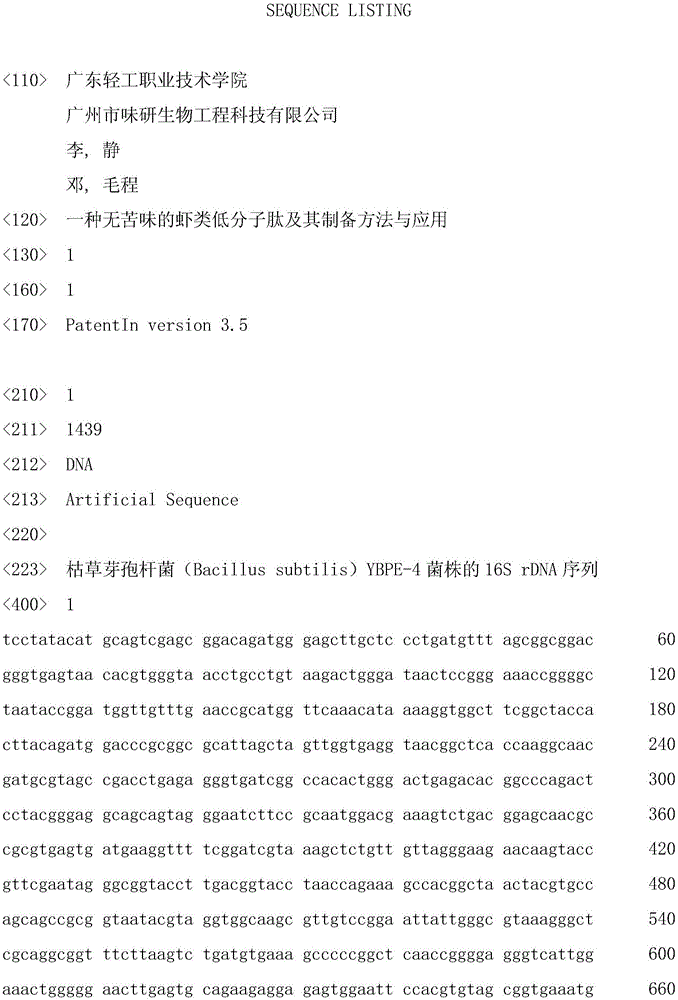

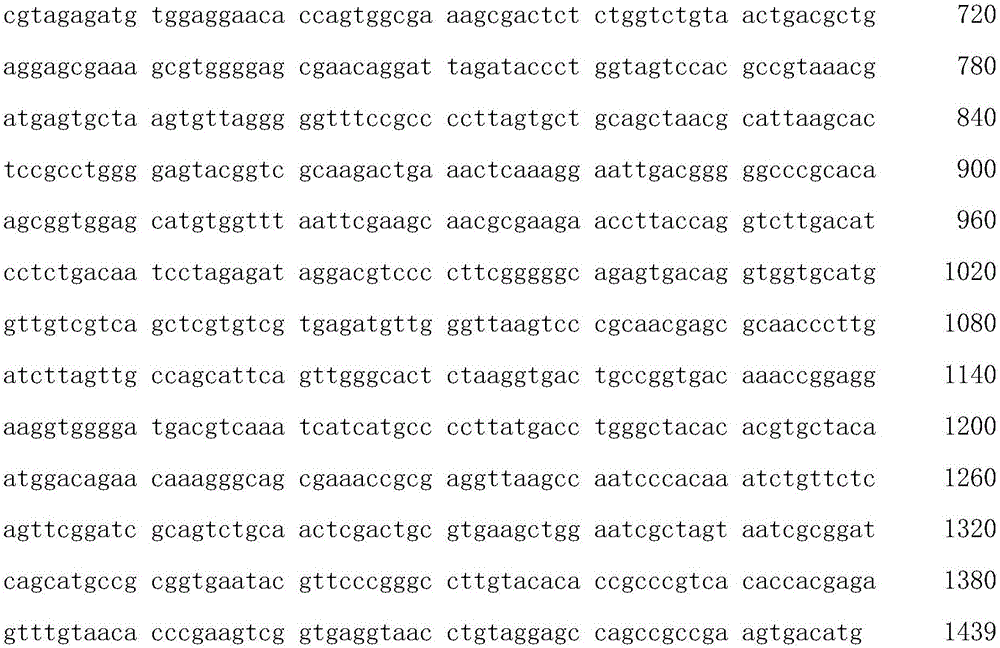

[0051] (1) Isolation and screening of high aminopeptidase-producing strains

[0052] Enrichment medium: glucose 50g / L, peptone 10g / L, KH 2 PO 4 2g / L, MgSO 4 ·7H 2 O0.5g / L, NaCl5g / L, pH7.0, sterilize at 121°C for 20min, cool for later use.

[0053] Plate separation medium: glucose 5g / L, casein 15g / L, KH 2 PO 4 1g / L, NaCl 5g / L, agar 20g / L, pH 7.0, sterilize at 121°C for 20min, cool for later use.

[0054] Slant medium: glucose 5g / L, peptone 5g / L, yeast extract 5g / L, NaCl 5g / L, agar 20g / L, pH7.0, sterilized at 121°C for 20min, cooled for later use.

[0055] Fermentation medium: soluble starch 40g / L, peptone 20g / L, KH 2 PO 4 1.5g / L, MgSO 4 ·7H 2 O 0.5g / L, pH7.0, sterilized at 121°C for 20min, cooled for later use.

[0056] Douchi is a commercially available material. 10 g of Douchi was added to 200 mL of enrichment medium, and cultured with shaking at 30° C. and 200 rpm for 16 hours. Dilute the culture solution in gradient, spread it on the plate separation medium, ...

Embodiment 2

[0067] (1) Shrimp enzymatic hydrolysis

[0068] Grind the dried shrimp through a 100-mesh sieve to obtain a powder; weigh 1200g of the powder (56.2% protein content), add 18L of water, and mix well; then add 56.2g of neutral protease, and enzymatically hydrolyze at 55°C for 4h , and then heated to 85°C for 12 minutes to inactivate the enzyme, and cooled to room temperature to obtain the enzymatic hydrolysis solution;

[0069] (2) Preparation of seed solution

[0070] Take 900mL of enzymolysis liquid, add 18g of soluble starch and 1.8g of potassium dihydrogen phosphate, adjust the pH to 7.0, and put it into five 1000mL Erlenmeyer flasks evenly, after sterilization and cooling, insert Bacillus subtilis YBPE-4 (CCTCC NO: M 2016359) slant strains, each bottle was inserted with 2 rings of bacterial lawn, cultivated at 37°C and 160rpm for 24h, and the bacterial concentration was 1.08×10 10 Individual / mL seed solution;

[0071] (3) Fermentation debittering of low molecular weight ...

Embodiment 3

[0076] (1) Shrimp enzymatic hydrolysis

[0077] Grind the dried shrimp through an 80-mesh sieve to obtain a powder; weigh 900g of the powder (56.2% protein content), add 18L of water, and mix well; then add 33.72g of neutral protease, and enzymatically hydrolyze at 50°C for 5h , then heated to 80°C, kept at a constant temperature for 15 minutes, inactivated the enzyme, cooled to room temperature, and obtained the enzymatic hydrolysis solution;

[0078] (2) Preparation of seed solution

[0079] Take 1800mL of enzymolysis solution, add 27g of soluble starch and 2.7g of potassium dihydrogen phosphate, adjust the pH to 6.5, and put it into ten 1000mL conical flasks evenly, after sterilization and cooling, insert Bacillus subtilis YBPE-4 (CCTCC NO: M 2016359) slant strains, each bottle was inserted with 2 rings of bacterial lawn, cultivated at 33°C and 200rpm for 28h, and the concentration of bacteria obtained was 2.49×10 10 Individual / mL seed solution;

[0080] (3) Fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com