Inorganic powder surface chemical plating method and thin film of inorganic powder

A technology of inorganic powder and surface chemistry, which is applied in the field of electroless plating, can solve problems such as complicated process, difficulty in completely covering the surface of powder, and improvement of inorganic powder electroless plating method, and achieves the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dry the 50-micron zeolite in a drying equipment at 100°C for 10 minutes until the water content is <0.1%; then stir the dried zeolite with a metal soap dispersant accounting for 2% by weight in a high-speed mixer, and set the temperature at 100°C Activate and mix at high temperature for 20 minutes, then add 1% paraffin wax accounting for zeolite weight and stir in a high mixer, mix at 90°C for 30 minutes, continue to add 6% zeolite weight urea, stir in a high mixer, and mix at 90°C 30 minutes; the obtained surface-modified inorganic powder is immersed in a tin protochloride solution with a pH of 1 for sensitization, the sensitization temperature is 90°C, the sensitization time is 5 minutes, and washed until neutral; then the obtained The powder is activated by immersing it in a palladium chloride solution with a pH of 4. The activation temperature is 40° C. and the activation time is 50 minutes. It is taken out, washed with deionized water, and dried at 40° C. for 20 min...

Embodiment 2

[0034] Dry 10 microns of diatomite in a drying device at 180°C for 20 minutes until the water content is <0.1%; then dry the diatomite after drying with 0.5% of diatomite weight aliphatic amide dispersant at high temperature Stir in the mixer, activate and mix at 160°C for 10 minutes, then add paraffin wax accounting for 5% by weight of diatomite, stir in a high-speed mixer, mix for 30 minutes at 90°C, continue to add melamine accounting for 1% by weight of diatomite The resin was stirred in a high mixer, and mixed for 30 minutes at 90°C; the obtained surface-modified inorganic powder was immersed in a stannous chloride solution with a pH of 3 for sensitization, the sensitization temperature was 30°C, and the sensitization time was 50 minutes, washed with water until neutral; next, immerse the obtained powder in a palladium chloride solution with a pH of 1 for activation. minute.

[0035] Preparation of electroless silver plating bath, the bath composition is: AgNO 3 (29 g / L...

Embodiment 3

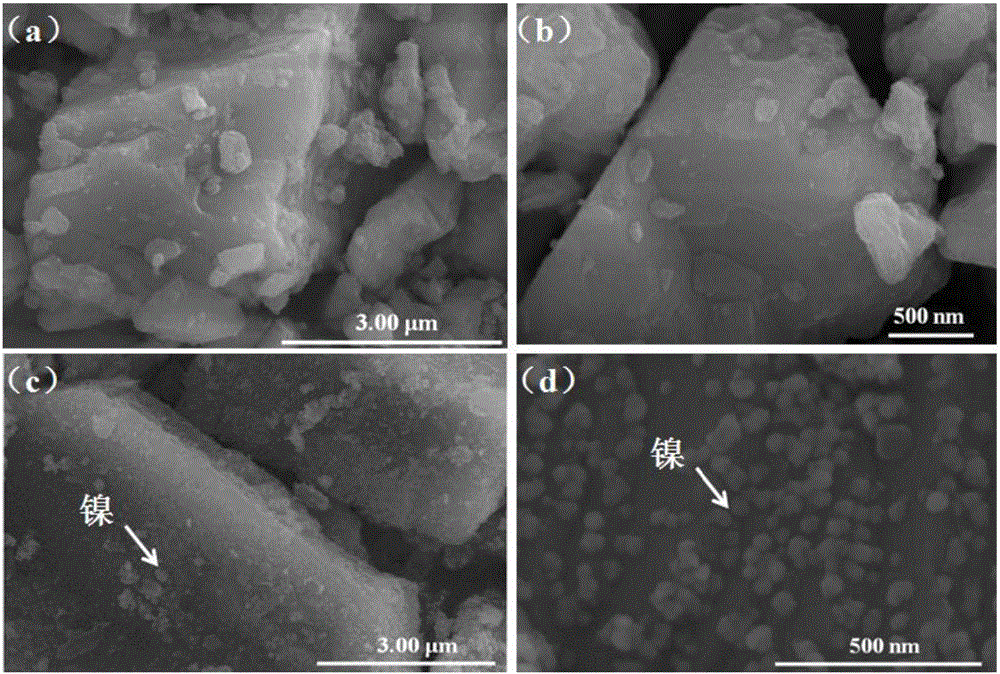

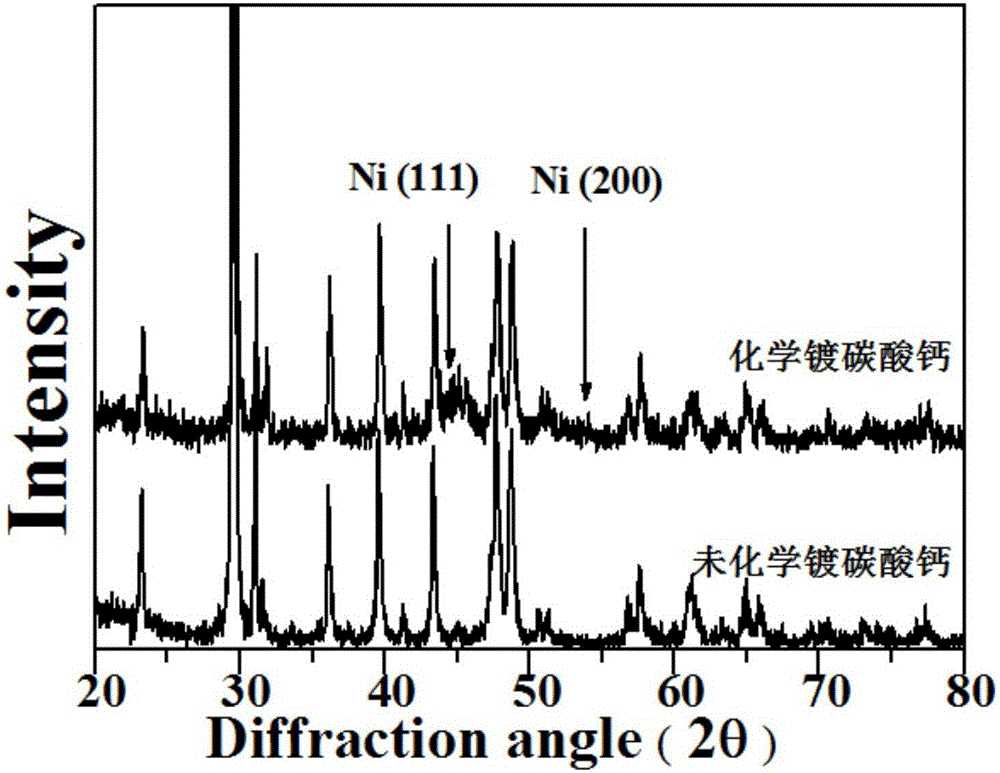

[0037]Dry the 85-micron calcium carbonate in the drying equipment at 145°C for 14 minutes until the water content is <0.1%; then stir the dried calcium carbonate with a fatty acid dispersant accounting for 1% of the weight of the calcium carbonate in a high mixer, Activation and mixing at 120°C for 15 minutes, then add 2% of the weight of calcium carbonate and stir in a high mixer, mix for 30 minutes at 90°C, continue to add 2.8% of the weight of calcium carbonate by silane coupling agent (KH550) Stir in a high-mixer, mix at 90°C for 30 minutes; immerse the obtained surface-modified inorganic powder in a stannous chloride solution with a pH of 2 for sensitization, the sensitization temperature is 80°C, and the sensitization time is 30 minutes , washed with water until neutral; next, the obtained powder was activated by immersing it in a palladium chloride solution with a pH of 2.8. The activation temperature was 60°C, and the activation time was 30 minutes. It was taken out wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com