Method for wet-process extraction of alumina from high-aluminum fly ash

A high-alumina fly ash and alumina technology, which is applied to the removal of alumina/hydroxide and solid waste, can solve the problems of harsh reaction conditions, acid process equipment corrosion, and difficult operation, and achieve low equipment material requirements , Reduce production energy consumption and avoid a large number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

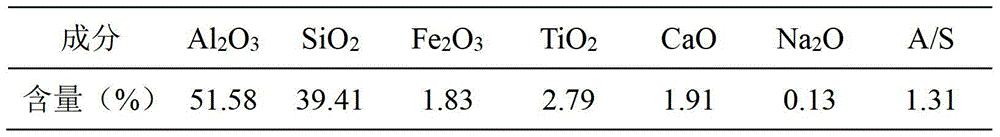

[0030] The raw material is high-alumina fly ash from a place in Inner Mongolia as an example, and its main chemical composition is shown in Table 1:

[0031] Table 1 Chemical composition of high alumina fly ash

[0032]

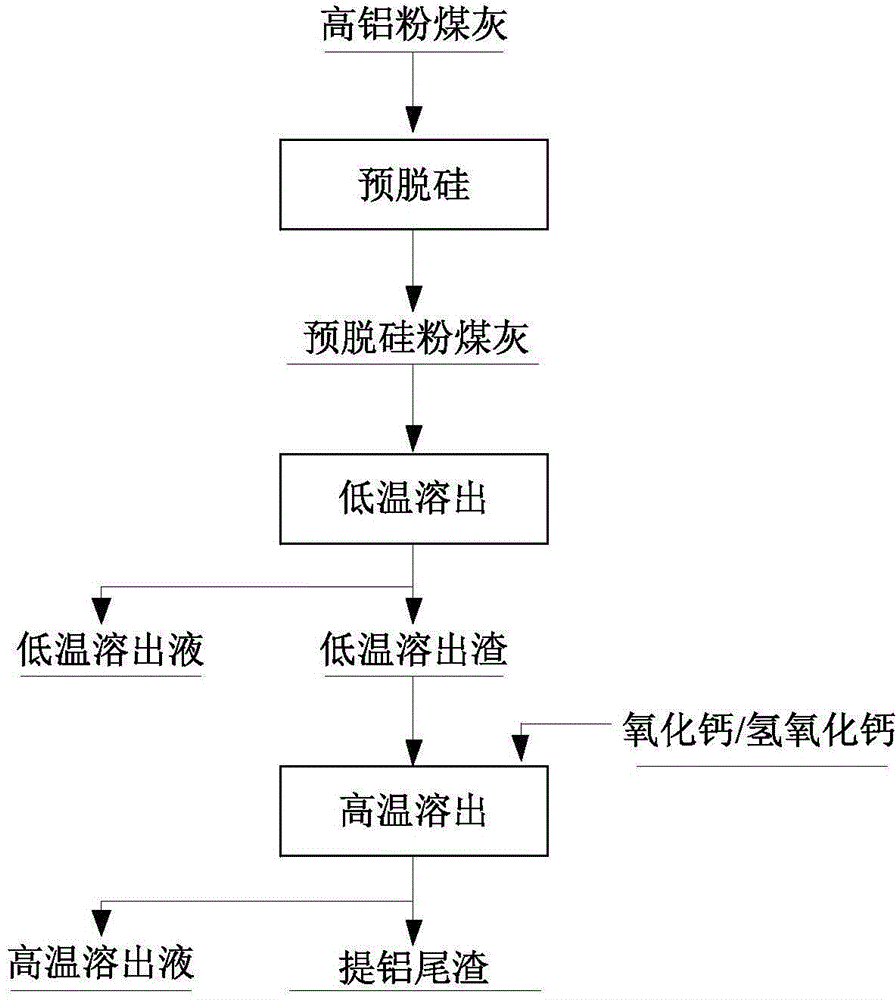

[0033] Such as figure 1 Shown, a kind of method of wet extraction alumina from high aluminum fly ash, described method may further comprise the steps:

[0034] 1. the high-alumina fly ash described in Table 1 is mixed with 13.5% sodium hydroxide solution by volume to mass ratio of 5:1 (ml / g) with the mass fraction, and the pre-desilication reaction is carried out in the reactor. The temperature is 100°C, and the reaction time is 2 hours. After the reaction, the pre-desiliconized fly ash and the desiliconized liquid are obtained by filtration and separation; after the pre-desiliconized fly ash is washed and dried, the A / S is measured to be 2.4.

[0035] 2. Combine the dried pre-desiliconized fly ash with sodium oxide concentration of 600g / L, Na2 O and Al ...

Embodiment 2

[0041] Such as figure 1 Shown, a kind of method of wet extraction alumina from high aluminum fly ash, described method may further comprise the steps:

[0042] 1. the high-alumina fly ash described in Table 1 and the mass fraction are 20% sodium hydroxide solution by volume and mass ratio is 3: 1 (ml / g) mix, carry out pre-desilication reaction in reactor, reaction temperature The temperature is 120°C, and the reaction time is 0.5h. After the reaction is completed, the pre-desiliconized fly ash and the desiliconized liquid are obtained by filtration and separation; after the pre-desiliconized fly ash is washed and dried, the measured A / S is 2.4.

[0043] 2. The dried pre-desiliconized fly ash and sodium oxide concentration 400g / L, Na 2 O and Al 2 o 3 The sodium aluminate solution with a molar ratio of 20 or 10 is mixed according to the volume to mass ratio of 3:1 (ml / g), placed in a reaction kettle, and kept at 110°C for 1d for low-temperature wet dissolution reaction, and f...

Embodiment 3

[0049] 1. the high-alumina fly ash described in Table 1 is mixed with 10% sodium hydroxide solution by volume to mass ratio as 6:1 (ml / g) with the mass fraction, and the pre-desilication reaction is carried out in the reactor, and the reaction temperature The temperature is 80°C, and the reaction time is 2 hours. After the reaction is completed, it is filtered and separated to obtain the pre-desiliconized fly ash and desiliconized liquid; after the pre-desiliconized fly ash is washed and dried, the measured A / S is 2.4

[0050] 2. The dried pre-desiliconized fly ash and sodium oxide concentration 500g / L, Na 2 O and Al 2 o 3 The sodium aluminate solution with a molar ratio of 30 or 13 is mixed according to the volume to mass ratio of 4:1 (ml / g), placed in a reaction kettle, and kept at 140°C for 0.5d for low-temperature wet dissolution reaction. Filtration and separation to obtain low-temperature dissolution slag and low-temperature dissolution liquid, the concentration of sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com