Anti-salting-out and anti-whiskering seal primer and preparation method thereof

A sealing primer and anti-pan-alkali technology, applied in the coating and other directions, can solve problems such as affecting the appearance and decorative effect of the paint film, and achieve the effects of increasing adhesion and alkali resistance, good film-forming effect, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

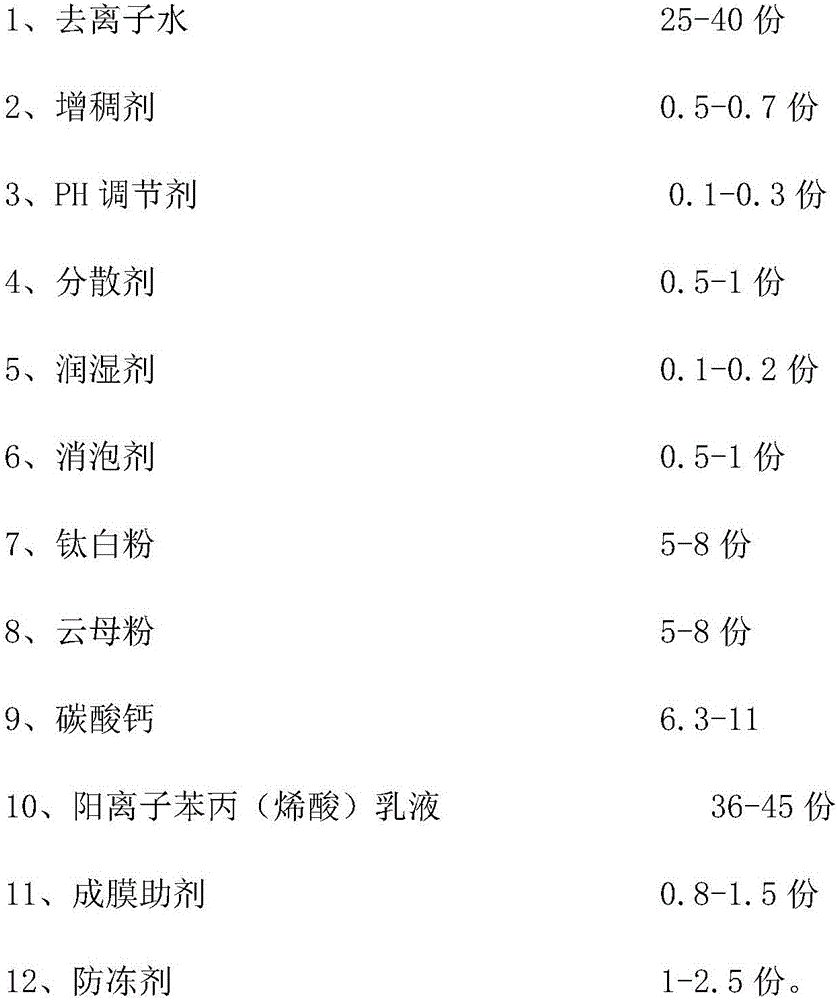

[0037] The preparation method of described anti-salt-alkali primer, is characterized in that: comprises the steps:

[0038] (1) Control the stirring rate to 300-500rmp, add 25-40 parts of deionized water, 0.5-0.7 parts of thickener and 0.1-0.3 parts of PH regulator to the mixer in sequence, and stir for 5-10 minutes;

[0039] (2) Then increase the speed to 800-1000rmp, add 0.1-0.2 parts of wetting agent, 0.5-1 part of dispersant, 0.5-1 part of defoamer, 5-8 parts of titanium dioxide and 5-8 parts of mica powder, 6.3-11 parts of calcium carbonate, then increase the speed to 1800-2000rmp, and stir for 15-20min;

[0040] (3) Finally, reduce the speed to 1000-1200rmp, add 36-45 parts of emulsion, 0.8-1.5 parts of film-forming aid and 1-2.5 parts of antifreeze in sequence, stir for 10-15 minutes and sieve with 200-300 mesh, that is Obtain the product of the present invention.

[0041] 2. Preparation of saline-alkali resistant primer

[0042]

[0043] (two) embodiment:

Embodiment 1

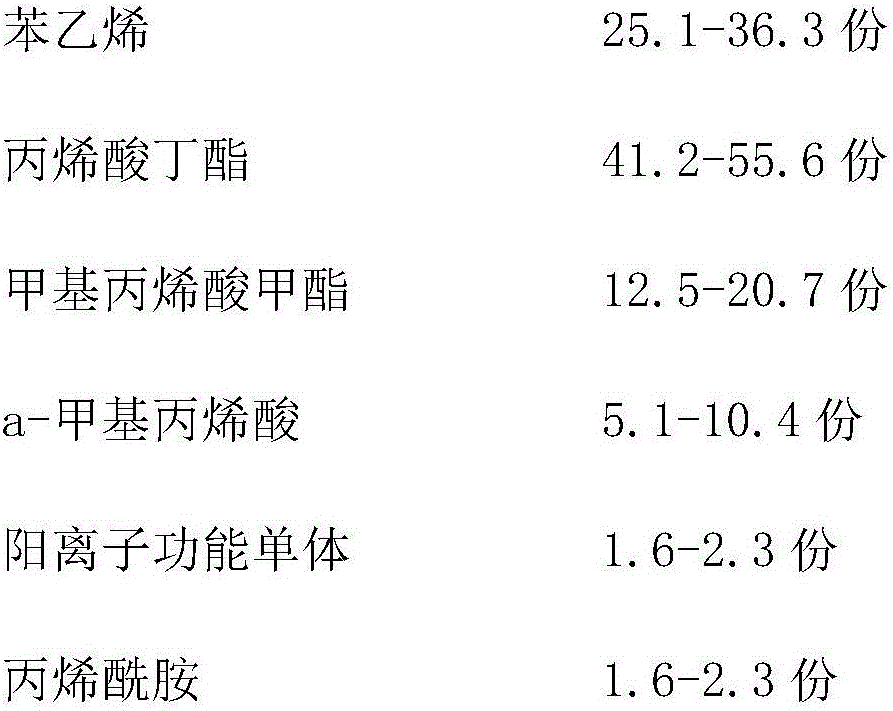

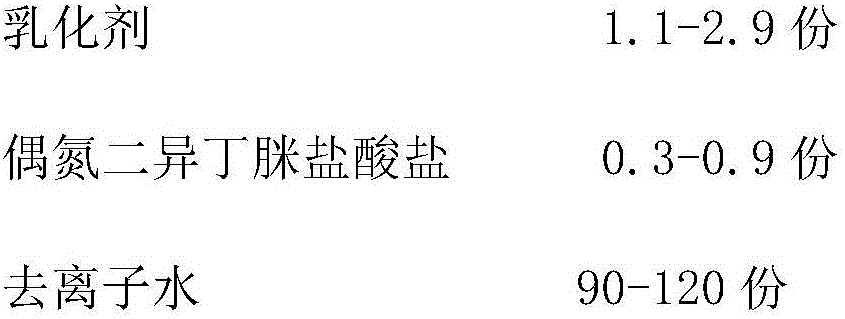

[0045] Preparation of cationic styrene-acrylic emulsion

[0046]

[0047] Described cationic styrene-acrylic emulsion is formulated according to the following steps:

[0048]Add 25.1 parts of styrene, 41.2 parts of butyl acrylate, 12.5 parts of methyl methacrylate, 5.1 parts of a-methacrylic acid, and 1.6 parts of cationic functional monomer , 1.6 parts of acrylamide, 2.2 parts of emulsifier and 80 parts of deionized water, control the stirring rate to 1000rmp, stir for 15min, and obtain the monomer pre-emulsion, then when the temperature is raised to 75°C, the stirring speed is 200rmp, slowly dropwise add the 0.6 parts of azobisisobutylamidine hydrochloride and 10 parts of water azobisisobutylamidine hydrochloride solution, the time of dropping is 1.5h, after the dropwise addition is completed, it is incubated for 1h, and the material is discharged at room temperature to obtain the cationic phenylpropanoid lotion.

[0049] 2. Preparation of saline-alkali resistant primer...

Embodiment 2

[0057] Preparation of cationic styrene-acrylic emulsion

[0058]

[0059]

[0060] Described cationic styrene-acrylic emulsion is formulated according to the following steps:

[0061] Add 31.1 parts of styrene, 49.3 parts of butyl acrylate, 18.5 parts of methyl methacrylate, 8.6 parts of a-methacrylic acid, and 2.3 parts of cationic functional monomer , 1.9 parts of acrylamide, 2.9 parts of emulsifier and 85 parts of deionized water, control the stirring rate to 1200rmp, and stir for 15-30min to obtain a monomer pre-emulsion, then when the temperature is raised to 80°C, the stirring speed is 300rmp, slowly Add azobisisobutylamidine hydrochloride solution containing 0.3 parts of azobisisobutylamidine hydrochloride and 25 parts of water, the time for the dropwise addition is 1.8 hours, after the completion of the dropwise addition, keep it warm for 1.5 hours, and discharge at room temperature to obtain Cationic styrene-acrylic emulsion.

[0062] 2. Preparation of saline-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com