Method for producing L-diaminocaproic acid through multistage continuous fermentation

A lysine and fermenter technology, applied in the field of L-lysine preparation, can solve the problems of reducing the utilization rate of the product, affecting the yield of the product, etc., and achieve the advantages of high utilization rate of the substrate, stable yield and lower production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

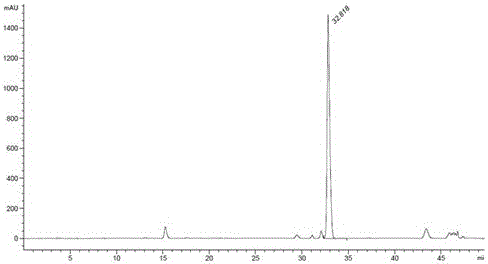

Image

Examples

Embodiment 1

[0028] A method for producing L-lysine by multistage continuous fermentation, comprising the following steps:

[0029] Step 1, prepare shake flask medium, seed medium, initial fermentation medium, carbon source feed tank culture fluid, nitrogen source feed tank culture fluid and medium feed tank culture fluid, the formula is as follows:

[0030] Shake flask medium: sucrose 8g / L (dissolved), ammonium sulfate 2g / L, yeast extract 5g / L, peptone 10g / L, K 2 HPO 4 .3H 2 02g / L, monosodium glutamate 2g / L, pyruvic acid 0.5g / L, MgSO 4 0.4g / L, FeSO 4 .7H 2 0 0.01g / L, L-threonine 0.2g / L, biotin 5mg / L. PH6.8-7.0.

[0031] Seed medium: sucrose 25g / L (divided), yeast extract 5g / L, ammonium sulfate 10g / L, K 2 HPO 4 .3H 2 0 1g / L, MSG 2.5g / L, pyruvic acid 0.5g / L, MgSO 4 0.4g / L, FeSO 4 .7H 2 0 0.01g / L, L-threonine 0.2g / L, biotin 2.5mg / L, nicotinamide 1.5mg / L, thiamine 0.45mg / L, pH6.8-7.0.

[0032] Initial fermentation medium: glucose 40 g / L (divided), ammonium sulfate 20 g / L, potas...

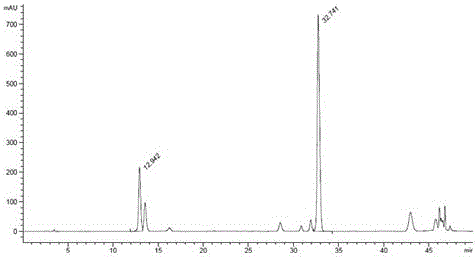

Embodiment 2

[0040] Steps 1-3 are the same as in Example 1, wherein the sugar used in the fermentation medium and the carbon source medium is starch saccharification solution.

[0041] Step 4: After connecting the sterilized fermentation tanks in series, insert 600ml of initial fermentation medium into the first-level fermentation tank, and feed in sterile air with an air volume of 0.04 / (min L), according to the inoculum size of 10% (v / v) Connect the first-level seed tank to cultivate mature strains, and the initial fermentation medium flows from the first-level fermentation tank into the second, third, and fourth levels. Use carbon source feeding tanks and medium feeding tanks to control the inflow of fermentation broth The rate is 100-120ml / h, the flow rate of the carbon source feed medium is controlled to 30ml / h, and the outflow rate of the fermentation broth is 130-150ml / h, so that the initial sugar concentration in the primary fermentation tank is 80g / L. During the continuous fermentat...

Embodiment 3

[0043] Steps 1-3 are the same as in Example 2.

[0044] Step 4: After connecting the sterilized fermentation tanks in series, insert 600ml of initial fermentation medium into the first-level fermentation tank, and inject sterile air with an air volume of 0.02L / (min·L), according to the inoculum size of 10 %(v / v) is connected to the first-level seed tank to cultivate mature strains, and the initial fermentation medium flows from the first-level fermenter to the second, third and fourth levels, and the carbon source feeding tank and the medium feeding tank are used to control the fermentation liquid The inflow rate is 50-70ml / h, the flow acceleration rate of the carbon source feeding tank culture fluid is 20-30ml / h, and the outflow rate of the fermentation broth is 80-100ml / h, so that the initial sugar concentration in the primary fermentation tank is 50g / L , in the continuous fermentation process, the sugar concentration in the fermentation tanks at all levels is as follows: fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com