Amino functional carbon-sulfur composite material of porous structure and preparation method and application of material

A technology of amino functionalization and porous structure, which is applied in the direction of structural parts, non-aqueous electrolyte battery electrodes, electrical components, etc., and can solve the problems of low electrode charging performance rate performance, lithium metal negative electrode corrosion and passivation, and positive electrode structure stability reduction, etc. problems, to achieve uniform distribution of pore structure, good reproducibility, and reduce the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

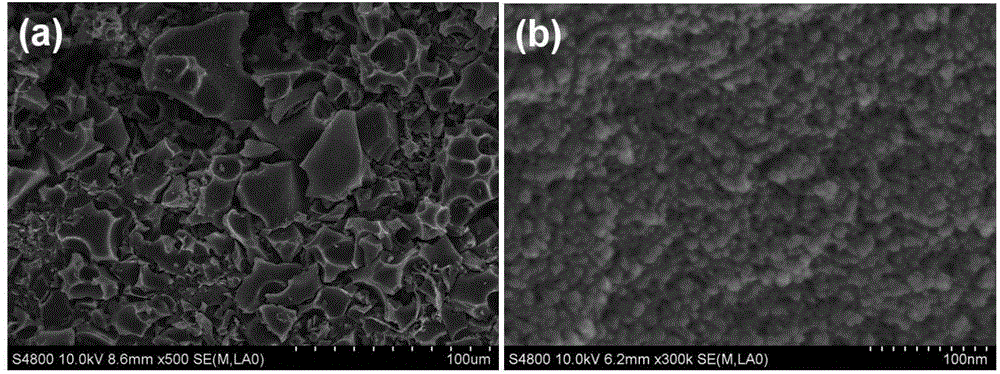

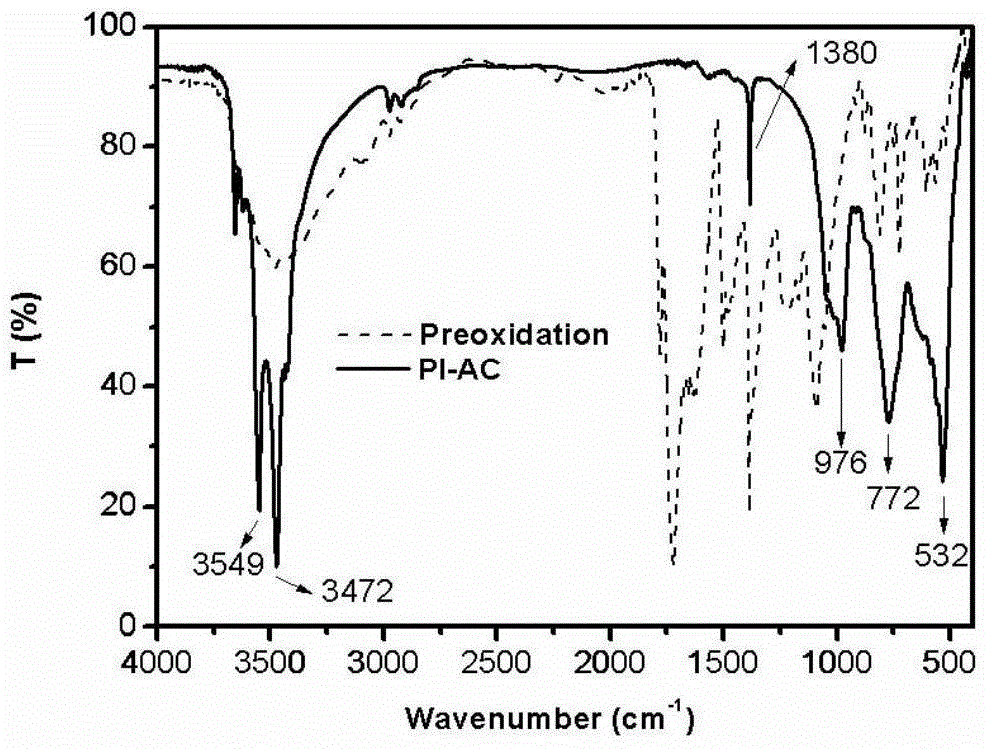

[0034] 1. The synthesis steps of the amino-functionalized porous carbon material precursor are as follows: a polyimide waste (PI) is processed into a sheet, and placed in a tube furnace, and heated at 2 °C in an air atmosphere. / min raised to 500°C and maintained for 0.5h, cooled to room temperature to obtain the pre-oxidized product. Then the obtained preoxidized product and potassium hydroxide were dispersed into 6ml of water at a ratio of 1:4, soaked at room temperature for 2 hours, then transferred to a drying oven, and evaporated to dryness at 100°C. Then transfer the product to a porcelain boat, raise it to 800°C at 5°C / min under a nitrogen atmosphere and keep it for 1h, after cooling to room temperature, wash with water, pickle, and wash with water to obtain a carbon material precursor with a porous structure containing amino functional groups Body (PI-AC), the structure and morphology are as follows figure 1 shown. Its infrared spectrum is as image 3 shown.

[003...

Embodiment 2

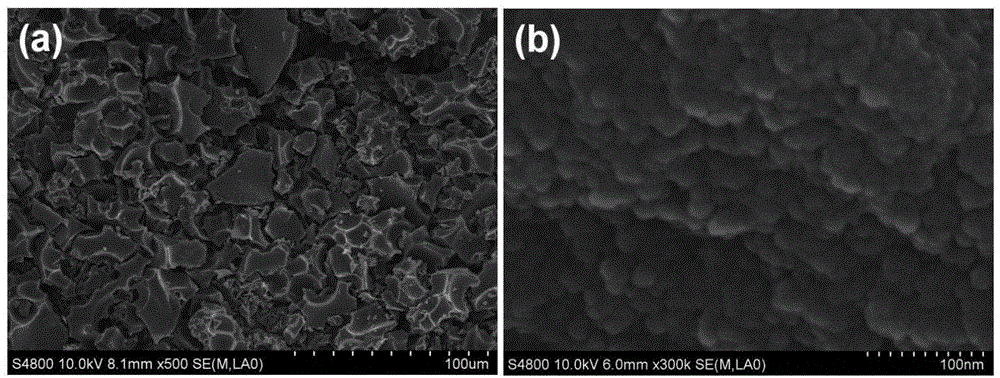

[0039] 1. The synthesis steps of the amino-functionalized porous carbon material precursor are as follows: a polyimide waste (PI) is processed into a sheet, and placed in a tube furnace, and heated at 2 °C in an air atmosphere. / min raised to 500°C and maintained for 0.5h, cooled to room temperature to obtain the pre-oxidized product. Then the obtained preoxidized product and potassium hydroxide were dispersed in 8ml of water at a ratio of 1:5, soaked at room temperature for 2h, then transferred to a drying oven, and evaporated to dryness at 100°C. Then transfer the product to a porcelain boat, raise it to 800°C at 5°C / min in a nitrogen atmosphere and keep it for 2h, after cooling to room temperature, wash with water, pickle, and wash with water to obtain a carbon material precursor with a porous structure containing amino functional groups Body 2.

[0040] 2. The synthesis of carbon-sulfur composite material (PI-AC / S) with amino-functionalized porous structure, the specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com