Waste gas treatment method and waste gas treatment equipment in sodium hydrosulfite production

A technology for waste gas treatment and hydrosulfite, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of insufficient purification degree, low purification efficiency, and inability to effectively handle toxic substances, so as to improve efficiency and reduce pollution. Concentration, the effect of strong redox ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

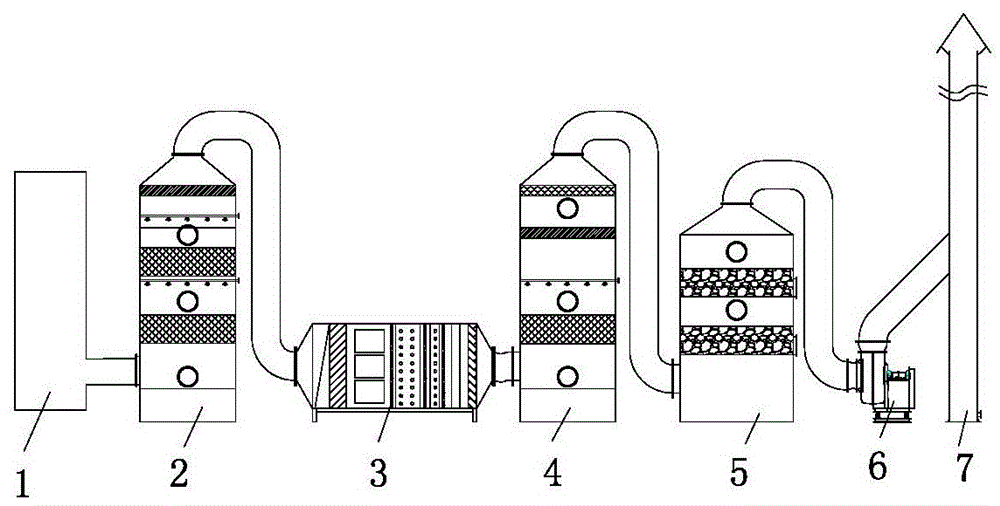

Image

Examples

Embodiment 1

[0043] A kind of waste gas processing method in the production of sodium hydrosulfite of the present embodiment, comprises the following steps:

[0044] Step 1, preprocessing:

[0045] (1) Methanol absorption: Pass the exhaust gas through a -50°C methanol solution to absorb sulfides, aldehydes, and ethylene oxide in the exhaust gas;

[0046] (2) Condensation: Use -60°C condensate to condense the gas in (1) to remove condensed substances, where the condensate is sulfur dioxide-methanol condensate;

[0047] (3) Alkali washing: wash the gas in (3) with lye to further remove sulfides, aldehydes, ethylene oxide, acidic substances and water-soluble substances in the gas to obtain pretreated gas;

[0048]Step 2, lye spray: introduce the gas obtained in step 1 into the purification alkali washing tower, and under the spray absorption of 2% sodium hydroxide solution, remove the gas soluble in water and neutralize the gas in the gas Acid gas, the gas whose concentration of toxic gas i...

Embodiment 2

[0054] A kind of waste gas processing method in the production of sodium hydrosulfite of the present embodiment, comprises the following steps:

[0055] Step 1, preprocessing:

[0056] (1) Methanol absorption: Pass the exhaust gas through a methanol solution at 10°C to absorb sulfides, aldehydes, and ethylene oxide in the exhaust gas;

[0057] (2) Condensation: Use -30°C condensate to condense the gas in (1) to remove the condensed substance, where the condensate is sulfur dioxide-methanol condensate;

[0058] (3) Alkali washing: wash the gas in (3) with lye to further remove sulfides, aldehydes, and ethylene oxide in the gas to obtain pretreated gas;

[0059] Step 2, lye spray: the gas obtained in step 1 is introduced into the purification alkali washing tower, and under the spray absorption of sodium carbonate solution, the gas soluble in water and the acid gas in the gas are removed to obtain The gas whose concentration of toxic gas drops, in addition, it is necessary to ...

Embodiment 3

[0065] A kind of waste gas processing method in the production of sodium hydrosulfite of the present embodiment, comprises the following steps:

[0066] Step 1, preprocessing:

[0067] (1) Methanol absorption: Pass the exhaust gas through a methanol solution at -20°C to absorb sulfides, aldehydes, and ethylene oxide in the exhaust gas;

[0068] (2) Condensation: Use 0°C condensate to condense the gas in (1) to remove condensed substances, where the condensate is sulfur dioxide-methanol condensate;

[0069] (3) Alkali washing: wash the gas in (3) with lye to further remove sulfides, aldehydes, and ethylene oxide in the gas to obtain pretreated gas;

[0070] Step 2, lye spray: introduce the gas obtained in step 1 into the purification alkali washing tower, and under the spray absorption of 2% sodium hydroxide solution, remove the gas soluble in water and neutralize the gas in the gas Acid gas, the gas whose concentration of toxic gas is reduced, in addition, it is necessary to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com