Modified direct-scraping thin-layer plastering mortar and construction method

A technology for plastering mortar and a construction method, applied in the field of building materials, can solve the problems of large overall thickness of the mortar layer, complicated construction procedures, and high engineering costs, and achieves hard hollowing and cracking. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

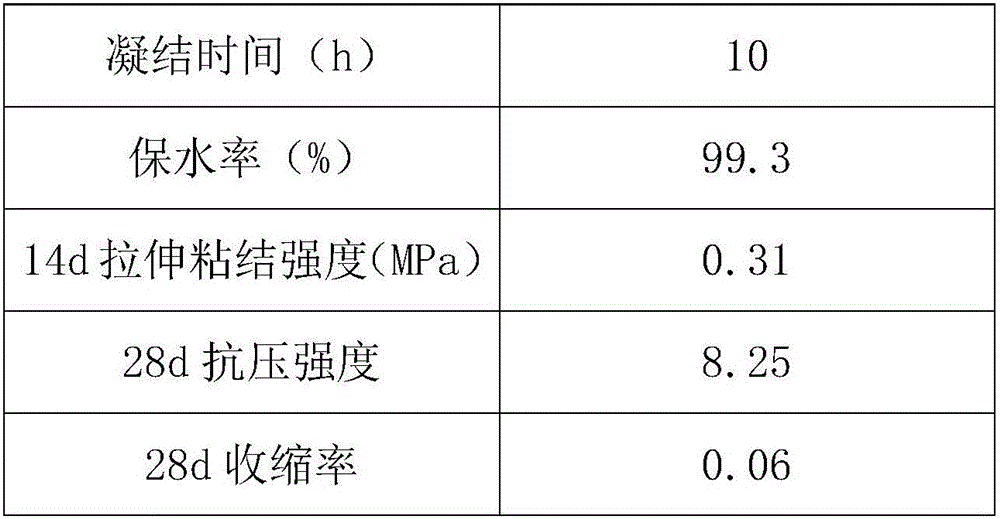

Embodiment 1

[0035] 1) A modified direct-scraped thin-layer plastering mortar with a strength grade of M5.0 for interior walls. Its components and parts by weight are: 160 parts of P.O42.5R cement, 760 parts of sand, and 80 parts of slag powder 160 parts of water, 0.8 parts of vinyl acetate and ethylene copolymer rubber powder, 0.6 parts of sodium carboxymethyl cellulose, 0.4 parts of alkali-resistant glass fiber, 0.2 parts of vermiculite powder, and 0.7 parts of multifunctional powder Including: calcium stearate waterproof 0.2 parts of sodium citrate, 0.2 parts of sodium citrate, and 0.2 parts of sulphoaluminate expansion agent. 2) Preparation and construction of a modified direct-scraping thin-layer plastering mortar:

[0036] ① Take the material according to the formula in 1, mix the ingredients except water together, stir evenly into powder A and set aside.

[0037] ②At the construction site, add water to powder A, stir evenly to form mortar A1, and the amount of water added is the am...

Embodiment example 2

[0047] 1) A modified straight-scraped thin-layer plastering mortar with a strength grade of M10 for external walls. Its components and parts by weight are: 170 parts of P.C52.5R cement, 760 parts of sand, 70 parts of heavy calcium powder, 165 parts of water, 0.9 parts of vinyl acetate homopolymer rubber powder, 0.5 parts of hydroxypropyl methyl cellulose, 0.2 parts of starch ether, 0.3 parts of polypropylene fiber, 0.2 parts of bentonite, 1 part of multifunctional powder Including: silicone waterproof powder 0.2 parts, 0.2 parts of citric acid, 0.3 parts of expansion agent, and 0.3 parts of early strength agent. 2) Preparation and construction of a modified direct-scraping thin-layer plastering mortar:

[0048] ① Take the material according to the formula in 1, mix the ingredients except water together, stir evenly into powder A and set aside.

[0049] ②At the construction site, add water to powder A, stir evenly to form mortar A1, and the amount of water added is the amount ...

Embodiment 3

[0058] 1) A modified straight-scraped thin-layer plastering mortar with a strength grade of M10 for the roof. Its components and parts by weight are: 180 parts of P.O42.5 cement, 750 parts of sand, 60 parts of silica fume powder, water 170 parts, 1 part of maleic acid and styrene copolymer rubber powder, 0.7 parts of crown rubber, 0.2 parts of starch ether, 0.5 parts of mineral wool fiber, 0.5 parts of attapulgite, 1.3 parts of multifunctional powder Including: silicone waterproof powder 0.3 0.3 part of sodium gluconate, 0.3 part of magnesium oxide expansion agent, and 0.4 part of early strength agent. 2) Preparation and construction of a modified direct-scraping thin-layer plastering mortar:

[0059] ① Take the material according to the formula in 1, mix the ingredients except water together, stir evenly into powder A and set aside.

[0060] ②At the construction site, add water to powder A, stir evenly to form mortar A1, and the amount of water added is the amount of water i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com