A kind of porphyrin phthalocyanine bilayer metal complex and its preparation method and application

A double-layer metal and porphyrin phthalocyanine technology, which is applied in the field of porphyrin phthalocyanine double-layer metal complexes and its preparation, can solve the problems of poor stability and high working temperature, achieve good practical value, low response concentration, The preparation method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

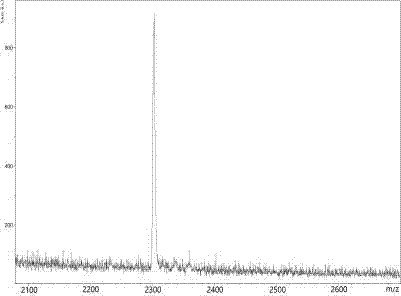

[0050] Embodiment 1 (preparation of Eu(TPyP){Pc-(OC 8 h 17 ) 8})

[0051] 1.1

[0052] 65 mg (0.1 mmol) of 5, 10, 15, 20-pyridylporphyrin 5,10,15,20-tetrakis(4-pyridyl)porphyrin (CAS No.: 16834-13-2;) and 45 mg Europium acetylacetonate (0.1 mmol) was dissolved in 6 mL of trichlorobenzene, nitrogen was used as a protective gas, and reacted at 190 °C for 6 hours. After the reaction was completed, trichlorobenzene was evaporated to dryness under reduced pressure and cooled. Add 238 mg (0.6 mmol) of 4,5-dioctyloxy-1,2-dicyanylbenzene (CAS No.: 118132-11-9) and 0.1 mL of 1,8-diazabicyclo[5.4.0] Undec-7-ene (CAS number: 6674-22-2) was reacted with n-octanol (8 mL) as the medium and nitrogen as the protective gas with stirring for 12 hours at a reaction temperature of 190 °C. After the reaction was completed, n-octanol was evaporated to dryness under reduced pressure and cooled. Using chloroform / methanol (volume ratio 100:6) as the eluent, the silica gel column was used for pu...

Embodiment 2

[0056] 2.1

[0057] ①Put the anodized aluminum film with a pore size of 200nm into a beaker, then place it in an ultrasonic cleaner, and use solvents of different polarities including water, ethanol, acetone, and chloroform to ultrasonically clean it for ten minutes in sequence, and then vacuum dry it for later use.

[0058] ② Dissolve 0.003mmol Eu(TPyP){Pc-(OC8H17)8} in 1 mL THF to obtain a THF solution of Eu(TPyP){Pc-(OC8H17)8}; (AAO) soaked in the tetrahydrofuran solution of Eu(TPyP){Pc-(OC8H17)8}, after standing for 8 hours, the tetrahydrofuran solution was sucked out, and dried in vacuum; Eu(TPyP){Pc-(OC8H17)8} containing AAO was obtained nanotube.

[0059] ③The Eu(TPyP){Pc-(OC8H17)8} nanotubes containing AAO were dissolved with 6 mol / L sodium hydroxide aqueous solution to remove the anodized aluminum oxide film, remove the liquid, and collect the solid product.

[0060] ④ The obtained Eu(TPyP){Pc-(OC8H17)8} nanotubes were washed with distilled water, and then diffused ...

Embodiment 3

[0086] Example 3 Preparation of Eu(TPyP){Pc-(OC8H17)8}Nanotube Nitrogen Dioxide Gas Sensor

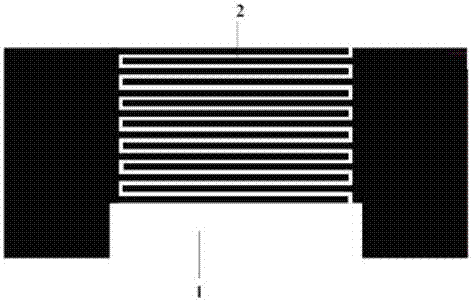

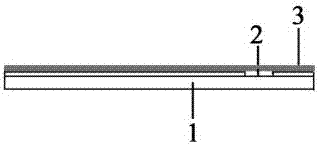

[0087] (1) The substrate of the ITO conductive glass interdigitated electrode was ultrasonically treated three times with toluene, acetone, ethanol, and deionized water, respectively, for five minutes each time, and vacuum-dried for later use.

[0088] (2) Use a dropper to drop-coat 1 mg of Eu(TPyP){Pc-(OC8H17)8} nanotubes prepared in Example 2 onto the interdigitated electrodes of the above-mentioned treated ITO conductive glass substrate, and let it dry naturally , that is, the gas sensor of the gas sensor (such as figure 1 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com