Environment-friendly treatment cable for water conservancy and hydropower construction sewage

An environmental protection treatment, water conservancy and hydropower technology, applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as unsatisfactory use requirements and cable performance limitations, and achieve the effects of soft texture, superior flame retardancy, and improved use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

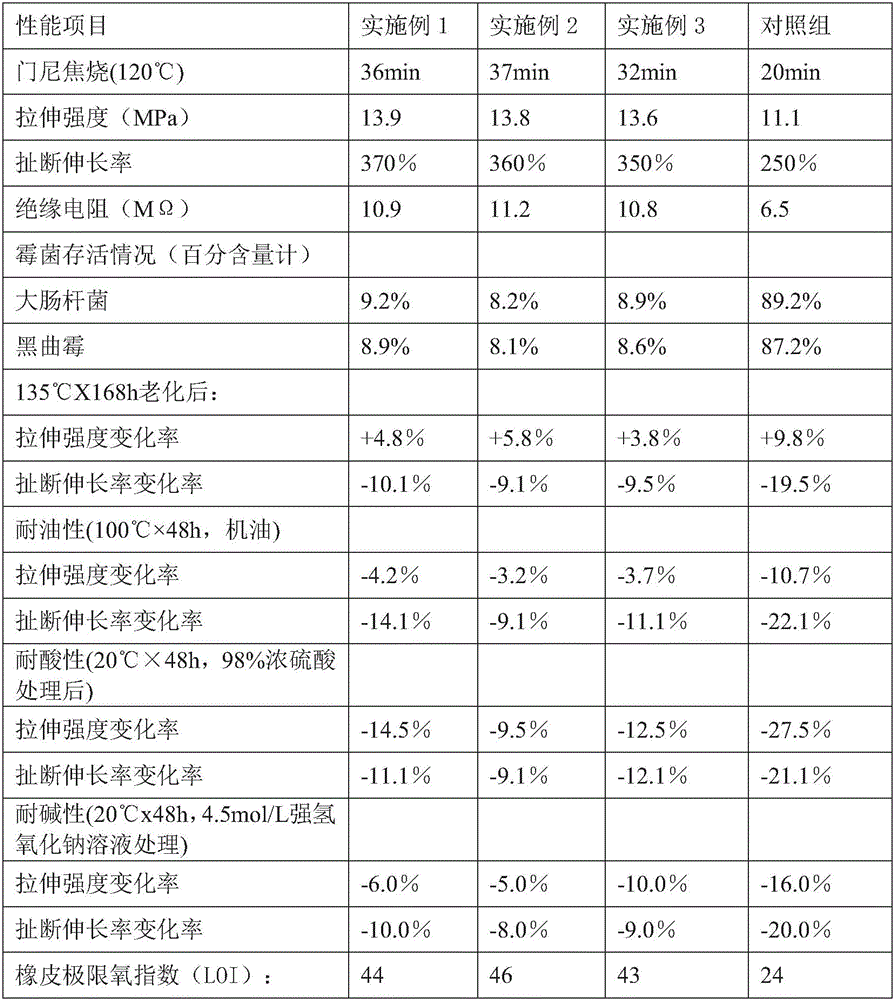

Examples

Embodiment 1

[0017] The cable for environmental protection treatment of water conservancy and hydropower construction sewage in this embodiment includes multiple copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered by a protective sleeve. The protective sleeve is composed of the following: Components in parts by mass: 24 parts of polystyrene, 22 parts of polyacrylic rubber, 22 parts of polyethylene terephthalate, 20 parts of tetraethyl silicate, 22 parts of walnut oil, 22 parts of epichlorohydrin , 20 parts of citronellyl formate, 22 parts of polyacrylic acid emulsion, 22 parts of chitosan, 20 parts of triethyltin chloride, 20 parts of nano-modified bamboo charcoal, 20 parts of nano-silver, 22 parts of ferrous sulfate, 20 parts of zinc sulfide 18 parts of attapulgite powder, 22 parts of boron nitride powder, 20 parts of lead difluoride powder, 18 parts of titanium dioxide powder, 20 parts of...

Embodiment 2

[0024]The cable for environmental protection treatment of water conservancy and hydropower construction sewage in this embodiment includes multiple copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered by a protective sleeve. The protective sleeve is composed of the following: Components in parts by mass: 26 parts of polystyrene, 24 parts of polyacrylic rubber, 24 parts of polyethylene terephthalate, 22 parts of tetraethyl silicate, 24 parts of walnut oil, 24 parts of epichlorohydrin , 22 parts of citronellyl formate, 24 parts of polyacrylic acid emulsion, 24 parts of chitosan, 22 parts of triethyltin chloride, 22 parts of nano-modified bamboo charcoal, 22 parts of nano-silver, 24 parts of ferrous sulfate, 22 parts of zinc sulfide 20 parts of attapulgite powder, 24 parts of boron nitride powder, 22 parts of lead difluoride powder, 20 parts of titanium dioxide powder, 22 parts of ...

Embodiment 3

[0031] The cable for environmental protection treatment of water conservancy and hydropower construction sewage in this embodiment includes multiple copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered by a protective sleeve. The protective sleeve is composed of the following: Components in parts by mass: 28 parts of polystyrene, 26 parts of polyacrylic rubber, 26 parts of polyethylene terephthalate, 24 parts of tetraethyl silicate, 26 parts of walnut oil, 26 parts of epichlorohydrin , 24 parts of citronellyl formate, 26 parts of polyacrylic acid emulsion, 26 parts of chitosan, 24 parts of triethyltin chloride, 24 parts of nano-modified bamboo charcoal, 24 parts of nano-silver, 26 parts of ferrous sulfate, 24 parts of zinc sulfide 22 parts of attapulgite powder, 26 parts of boron nitride powder, 24 parts of lead difluoride powder, 22 parts of titanium dioxide powder, 24 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com