Radiation protection water-in-water multicolor paint

A technology of water-in-water and colorful paint, which is applied in the field of coatings, can solve the problems of lack of radiation protection and stain resistance, poor UV resistance, and easy volatilization of organic solvents, so as to improve radiation protection, excellent aging resistance, Inhibits the effect of ubiquinol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

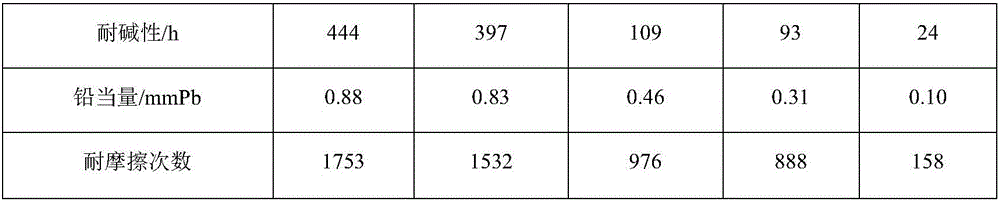

Examples

Embodiment 1

[0032] (1) Preparation of protective glue

[0033] Add 40 grams of water, 0.9 grams of sodium pyrophosphate, 0.2 grams of lignocellulose, and 1.5 grams of polyvinyl alcohol in sequence at a speed of 1000 r / min, and stir until the above ingredients are completely dissolved to obtain a protective glue;

[0034] (2) Preparation of base paint

[0035] Add 3 grams of hydroxypropyl methylcellulose, 2 grams of ethylene glycol, 5 grams of dimethyl sulfoxide, 2 grams of nano-titanium dioxide, 15 grams of kaolin, 15 grams of tourmaline powder, and octaphenyl cage-type polysaccharide 28 grams of siloxane-modified sulfonated polyimide, 0.3 grams of defoamer, 6 grams of bamboo charcoal powder, stirred at 1500 r / min for 10 minutes to obtain the base paint;

[0036] (3) Preparation of mixed solution

[0037] Mix the base paint prepared in step (2) and the protective glue prepared in step (1) uniformly to obtain the mixed solution of the base paint and the protective glue;

[0038] (4) col...

Embodiment 2

[0046] (1) Preparation of protective glue

[0047] Add 40 grams of water, 0.9 grams of sodium pyrophosphate, 0.2 grams of lignocellulose, and 1.5 grams of polyvinyl alcohol in sequence at a speed of 1000 r / min, and stir until the above ingredients are completely dissolved to obtain a protective glue;

[0048] (2) Preparation of base paint

[0049] Add 3 grams of hydroxypropyl methylcellulose, 2 grams of ethylene glycol, 5 grams of dimethyl sulfoxide, 2 grams of nano-titanium dioxide, 15 grams of kaolin, 15 grams of tourmaline powder, and octaphenyl cage-type polysaccharide 28 grams of siloxane-modified sulfonated polyimide, 0.3 grams of defoamer, 6 grams of bamboo charcoal powder, stirred at 1500 r / min for 10 minutes to obtain the base paint;

[0050] (3) Preparation of mixed solution

[0051] Mix the base paint prepared in step (2) and the protective glue prepared in step (1) uniformly to obtain the mixed solution of the base paint and the protective glue;

[0052] (4) col...

Embodiment 3

[0060] (1) Preparation of protective glue

[0061] Add 40 grams of water, 0.9 grams of sodium pyrophosphate, 0.2 grams of lignocellulose, and 1.5 grams of polyvinyl alcohol in sequence at a speed of 1000 r / min, and stir until the above ingredients are completely dissolved to obtain a protective glue;

[0062] (2) Preparation of base paint

[0063] Add 3 grams of hydroxypropyl methylcellulose, 2 grams of ethylene glycol, 5 grams of dimethyl sulfoxide, 2 grams of nano-titanium dioxide, 15 grams of kaolin, 15 grams of tourmaline powder, and octaphenyl cage-type polysaccharide 28 grams of siloxane-modified sulfonated polyimide, 0.3 grams of defoamer, 6 grams of bamboo charcoal powder, stirred at 1500 r / min for 10 minutes to obtain the base paint;

[0064] (3) Preparation of mixed solution

[0065] Mix the base paint prepared in step (2) and the protective glue prepared in step (1) uniformly to obtain the mixed solution of the base paint and the protective glue;

[0066] (4) col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com