One-dimensional photonic crystal structure color generation material and preparation method thereof

A dimensional photonic crystal and structural color-producing technology, which is applied in optics, optical components, instruments, etc., can solve the problems of uncontrollable structural color, layer thickness, and insufficient color, and achieve good application prospects and clear layer boundaries. , colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Weigh 80.0g of water, 2.0g of hexadecyltrimethylammonium bromide and 5.0g of methyl methacrylate and stir in the reaction bottle, stirring for 30min under nitrogen protection; Potassium was added to the reaction bottle, and reacted for 1 hour; 25.0 g of methyl methacrylate was dropped into the reaction bottle at a constant speed, and the drop was completed within 2 hours, and reacted for 1 hour to obtain the target polymethyl methacrylate microemulsion.

[0043] Measure 20 mL of isopropyl titanate into 30 mL of deionized water, stir at 400 rpm for 1 h; filter the precipitate and wash; dissolve the precipitate in deionized water, and add 3.9 mL of tetramethylammonium hydroxide; pour the above liquid into In the reaction kettle, react at 120°C for 3 hours to obtain titanium dioxide nano sol.

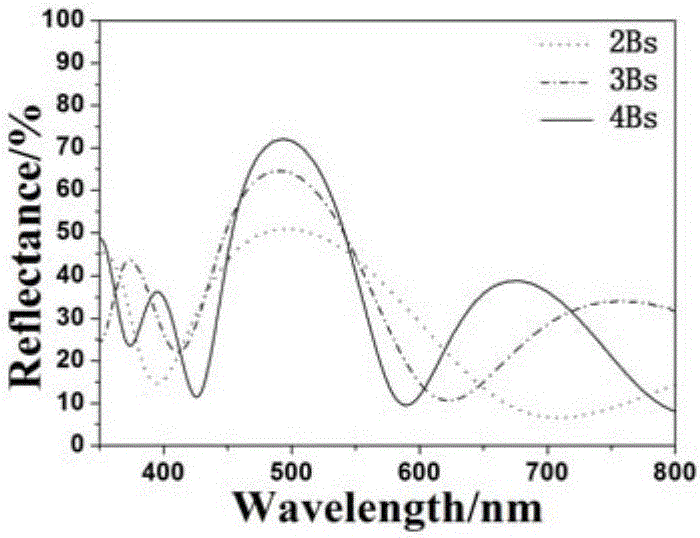

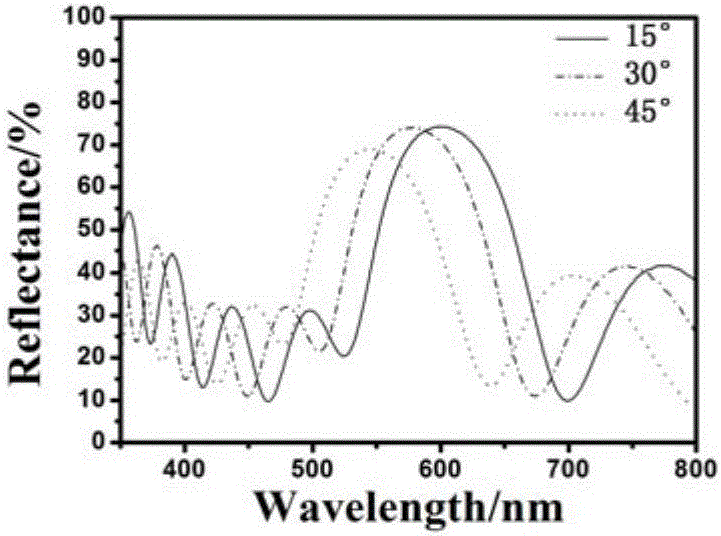

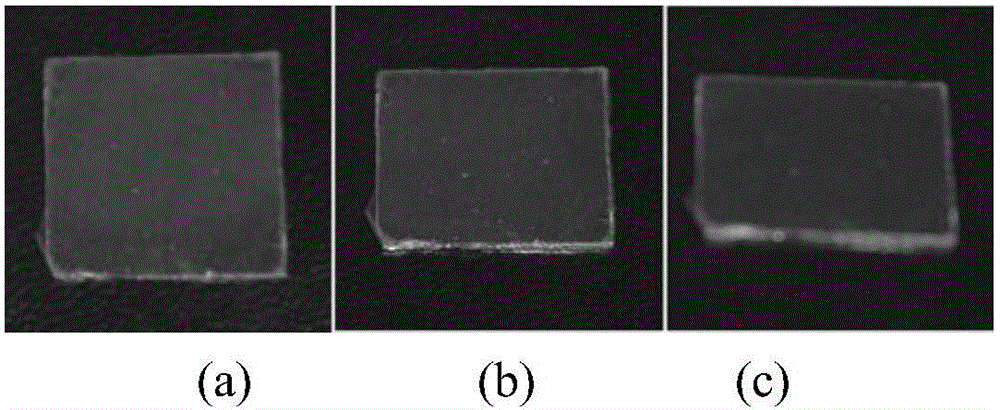

[0044] Take a polymethyl methacrylate microemulsion with a solid content of 2% and a titanium dioxide sol with a mass fraction of 3% and alternately spin-coat it on a silicon wafer a...

Embodiment 2-5

[0046] The method is the same as that in Example 1, but glass sheets, copper sheets, quartz sheets, and plastic sheets are used instead of silicon sheets as substrate materials to assemble one-dimensional photonic crystal structural color materials.

Embodiment 6

[0048] Weigh 80g of water, 2g of cetyltrimethylammonium bromide and 5g of mixed monomer (methyl methacrylate and acrylic acid molar ratio 10:1) and stir in a reaction flask, and stir for 30min under nitrogen protection; heat in a water bath until React at 60°C for 1 hour; add 0.09g of potassium persulfate into the reaction flask and react for 1 hour; drop 25g of mixed monomers into the reaction flask at a constant speed, and finish the dripping within 2 hours, then keep the temperature for 0.5 hours. A methyl methacrylate-acrylic acid copolymer microemulsion was obtained.

[0049] Measure 20 mL of isopropyl titanate into 30 mL of deionized water, stir at 400 rpm for 1 h; filter the precipitate, wash; dissolve the precipitate in deionized water, and add 3.9 mL of tetramethylammonium hydroxide; pour the above liquid Put it into a reaction kettle, and react at 120° C. for 3 hours to obtain titanium dioxide nano-sol.

[0050] Take a methyl methacrylate-acrylic acid copolymer micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com