Mixed inoculant for yoghurt fermentation

A technology of mixed bacterial agents and mixed starters, which is applied in the fields of application, milk preparations, dairy products, etc., can solve the problems of restricting the development of probiotic lactic acid bacteria industry and fermented dairy products, and high production costs, and achieve subtle whey precipitation with taste changes Less, improve the coagulation state, reduce the effect of whey separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1. proves the bacterial classification ratio of science by experiment

[0029] Using single factor experiment results and analysis:

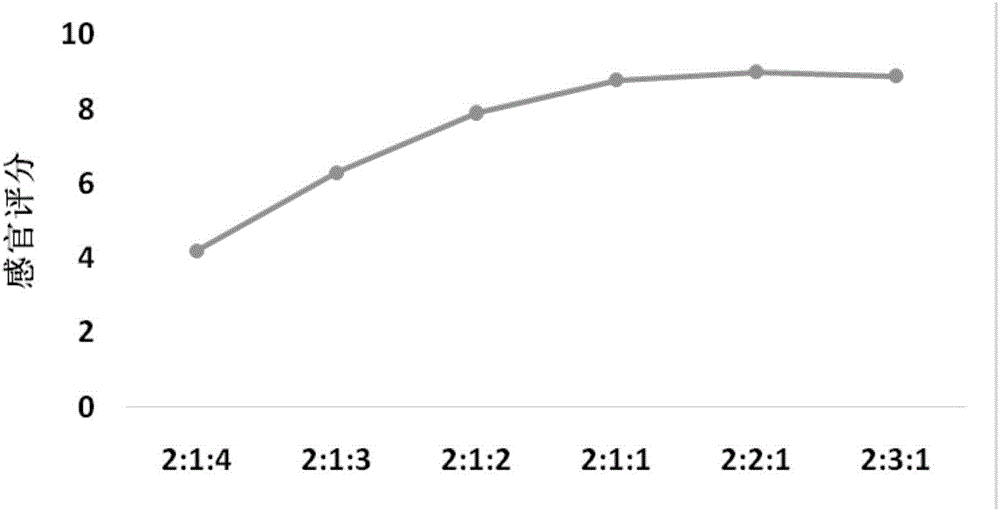

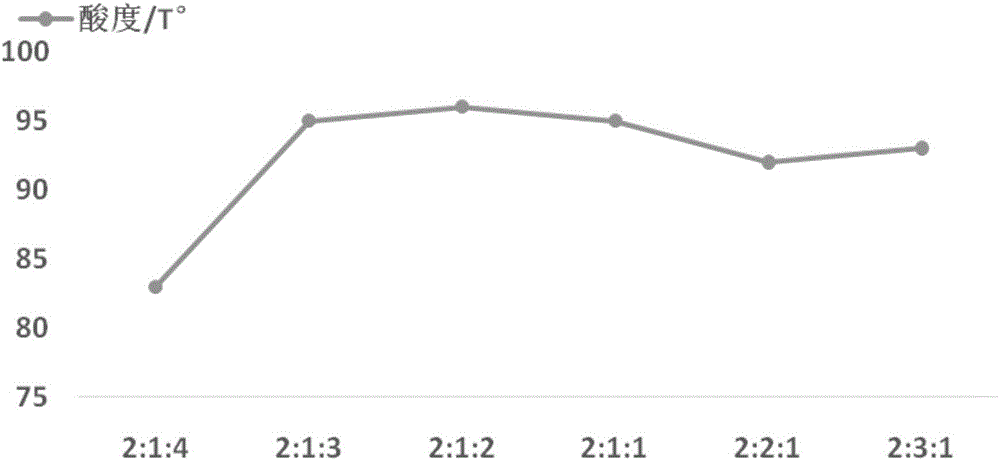

[0030] Determination of strain ratio (Streptococcus thermophilus + Lactobacillus bulgaricus): Bifidobacterium V9: Lactobacillus plantarum PP12, the experimental results are as follows figure 1 , figure 2 shown.

[0031] From figure 1 It can be seen from the figure that with the change of the ratio of strains, the comprehensive sensory score of yogurt also changes; from figure 2 It can be seen that the acidity of yogurt fermentation is too high or too low, and the overall score is not very high, which means that the acidity of yogurt must be moderate to suit people's taste. Therefore, the comprehensive evaluation considers the selection (Streptococcus thermophilus + Lactobacillus bulgaricus): the ratio of Bifidobacterium V9: Lactobacillus plantarum PP12 is 2:1:1.

Embodiment 2

[0032] Embodiment 2. Two kinds of strains play a synergistic effect

[0033] 1. Single strain growth

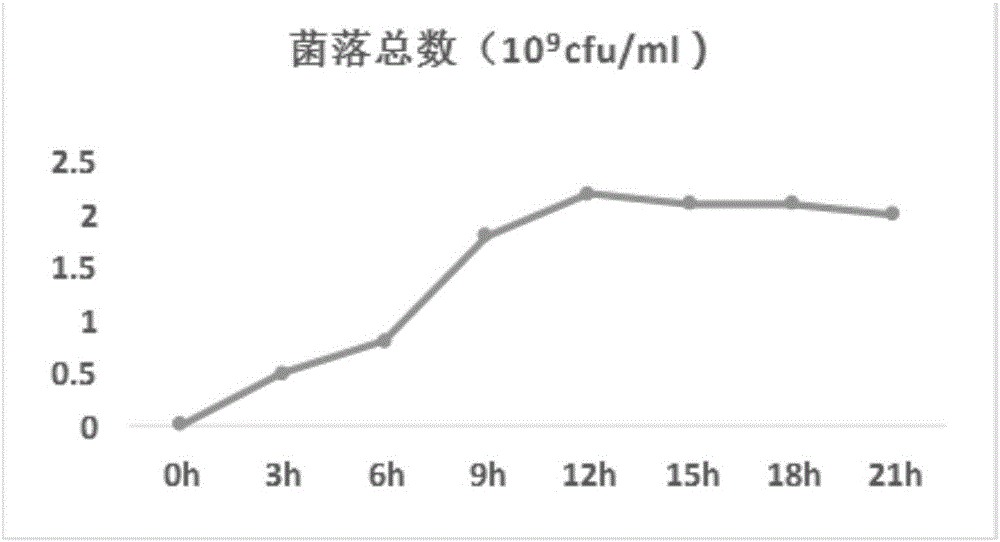

[0034] Study the growth process of Bifidobacterium V9 and Lactobacillus plantarum PP12 in skim milk medium, so as to understand the optimum harvest period of fermentation, and measure the growth curve. The inoculum size is 10 7 cfu / mL, 42 ℃ constant temperature culture, Bifidobacterium V9, Lactobacillus plantarum PP12 counted viable bacteria every once in a while, the specific growth changes are as follows image 3 , Figure 4 .

[0035] Depend on image 3 and Figure 4 It can be seen that Bifidobacterium V9 entered the logarithmic growth phase after a short delay period, reached a peak at 12 hours, and then entered a stable growth period. After that, the number of bacteria basically stopped increasing, and began to decline at 18 hours, entering the decline period. However, Lactobacillus plantarum PP12 grew slowly from the beginning. Compared with Bifidobacterium V9, it ...

Embodiment 3

[0039] Embodiment 3. Yogurt starter inhibits spoilage and the growth and reproduction of pathogenic bacteria

[0040] Harmful bacteria mainly refer to pathogenic bacteria, mold and so on. In addition, some facultative bacteria will also transform into harmful bacteria such as Escherichia coli and Bacteroides, which are not conducive to human health when the health of the body is in trouble. Probiotics must not only proliferate, but also inhibit the proliferation of harmful bacteria. It is confirmed by experiments that the starter has obvious inhibitory effect on harmful bacteria Clostridium, and has no proliferation effect on potential pathogenic bacteria (such as Enterobacter, Enterococcus). Experimental design (see Table 1), 12% skimmed milk culture medium (introduced strain starter and non-introduced strains), cultivated in a constant temperature incubator at 42°C under non-sterile conditions, cultivated for 12h, and detected the fermentation Various microbiological healt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com