Buckwheat protein concentrate with low phenol and low trypsin inhibitor and preparation method thereof

A technique of trypsin inhibition and protein concentration, which is applied in the field of deep processing of buckwheat grains, can solve the problems of affecting protein structure and properties, consumption of large acid-base solution, poor grain protein, etc., achieves high solubility and digestibility, and avoids tight combination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

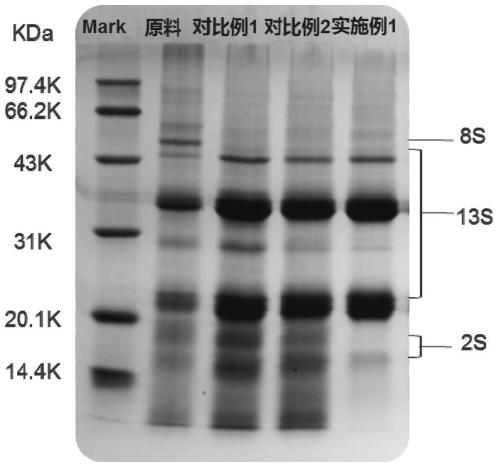

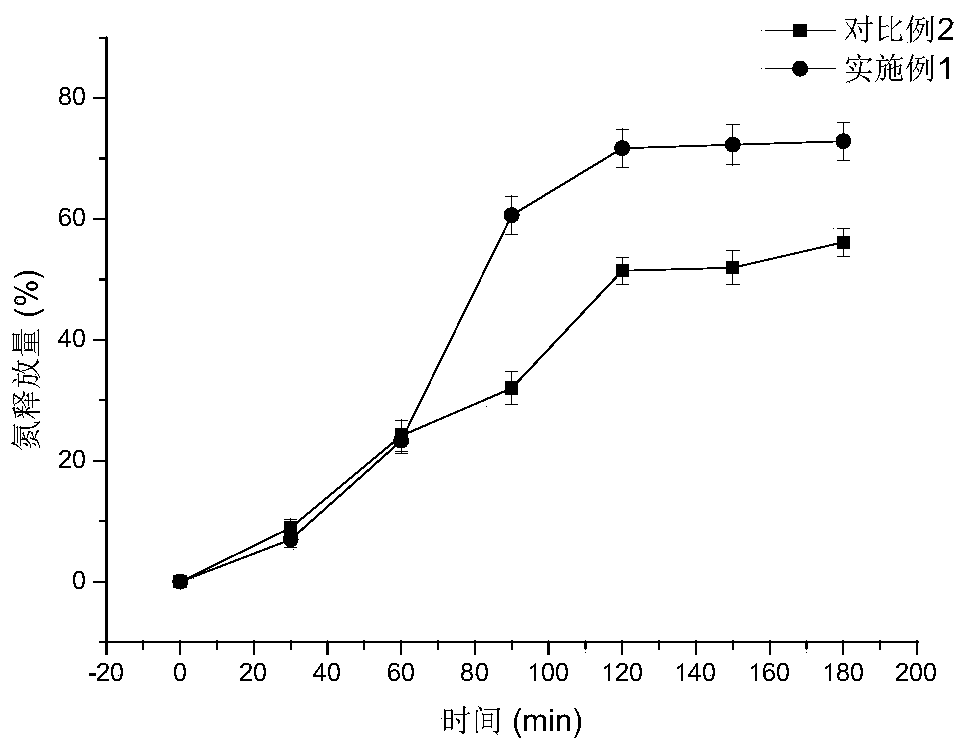

[0045] 40g tartary buckwheat powder and 0.033mol / L NaHCO 3 Mix with 0.086mol / L NaCl salt solution at a material-to-liquid ratio of 1:10 (w / v, mass unit is kg, volume unit is L), stir (300r / min) at room temperature 25°C for 12h, and then centrifuge at 8,000r / min 30min. Pre-activated XAD16HP macroporous resin 50g, wet packing column, using dynamic adsorption, the flow rate is controlled at 1 times the column volume per hour, and the sample solution is collected. Finally, dialyze at 4°C for 48 hours and freeze-dry to obtain buckwheat protein concentrate with low phenol and low trypsin inhibitor.

[0046] The recovery rate of polyphenols in this embodiment is 0.32%, and the protein sample is in the form of pure white powder, which can be quickly dissolved in distilled water with pH 7.0.

Embodiment 2

[0058] 20g tartary buckwheat powder and containing 0.033mol / L NaHCO 3 Mix with 0.086mol / L NaCl salt solution at a material-liquid ratio of 1:10 (w / v, mass unit is kg, volume unit is L), stir (300r / min) at room temperature 20°C for 3h, then 8,000r / min Centrifuge for 30min. Take the supernatant in a 1000mL Erlenmeyer flask, add 50g of activated XAD16N macroporous resin, and place it on a constant temperature shaker at 25°C with a rotation speed of 200rpm for static adsorption for 90min. Finally, it was dialyzed at 4°C for 48 hours and freeze-dried to obtain buckwheat protein with low phenol and low trypsin inhibitor.

[0059] The recovery rate of protein in this embodiment is 65.29%, the mass content of total phenols is 0.43%, and the recovery rate of polyphenols is 0.52%. The protein sample is in the form of pure white powder and can be quickly dissolved in distilled water at pH 7.0.

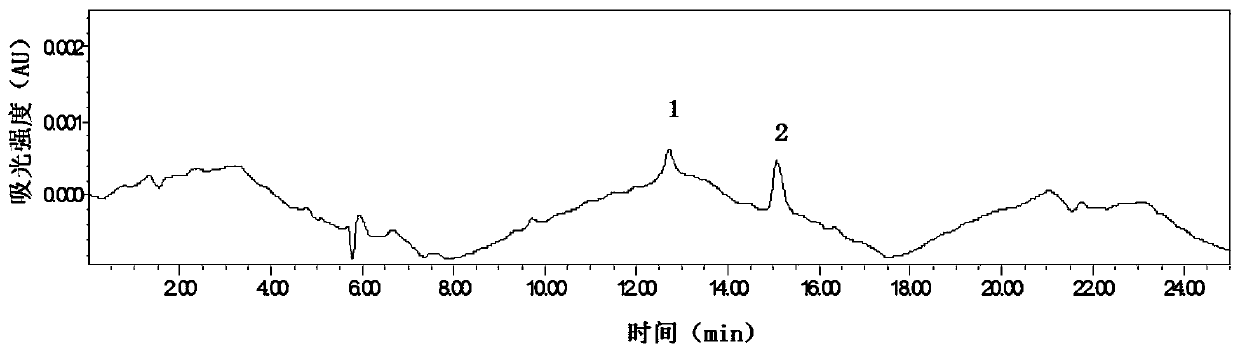

[0060] The sample was extracted with 70% methanol in an ultrasonic water bath, and after p...

Embodiment 3

[0062] 40g tartary buckwheat powder and 0.033mol / L NaHCO 3Mix with 0.086mol / L NaCl salt solution at a material-to-liquid ratio of 1:10 (w / v, mass unit is kg, volume unit is L), stir (300r / min) at room temperature 25°C for 6h, then 8,000r / min Centrifuge for 30min. Take the supernatant in a 1000mL Erlenmeyer flask, add 50g of activated XAD16N macroporous resin, and place it on a constant temperature shaker at 25°C with a rotation speed of 200rpm for static adsorption for 90min. Then use 10kDa polysulfone membrane ultrafiltration diafiltration, the flow rate is 600r / min, the diafiltration volume is 4 times the volume of the sample solution, the concentrated solution is collected, freeze-dried to obtain low-phenol and low-trypsin inhibitor buckwheat protein.

[0063] The recovery rate of protein in this embodiment is 65.16%, the mass content of total phenols is 0.42%, and the recovery rate of polyphenols is 0.53%. The protein sample is in the form of pure white powder and can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com