A kind of naringenin nano composition and its preparation method and application

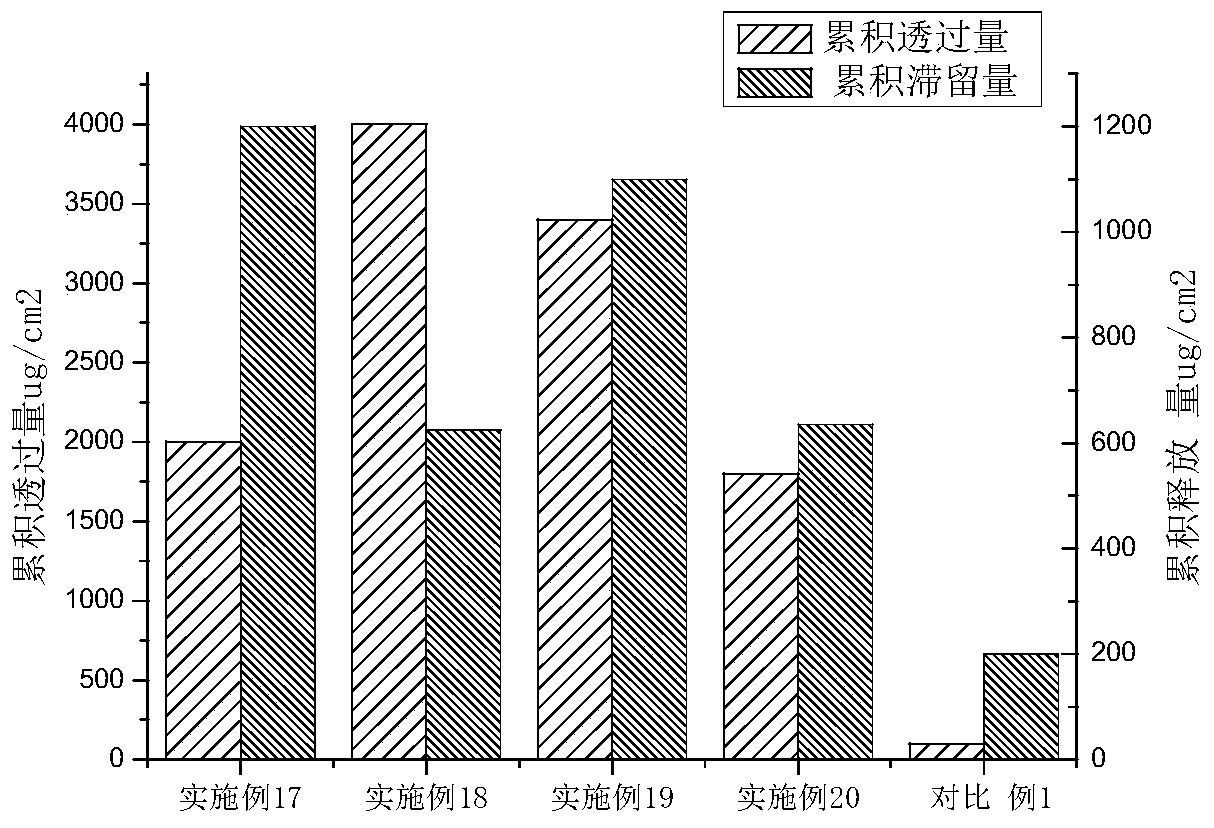

A nano-composition, naringenin technology, applied in the direction of application, drug combination, skin care preparations, etc., can solve the problem of poor skin permeability and retention, low fat solubility and water solubility of naringenin, which limit the wide range of naringenin Application and other issues, to achieve the effects of long residence time, increased drug encapsulation rate, excellent skin permeability and retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention provides the preparation method of the naringenin nano-composition described in above-mentioned scheme, comprises the steps:

[0044] (1) melting solid lipid, liquid lipid and caprylic acid macrogolglyceride to obtain an oil phase;

[0045] (2) mixing naringenin with polyols to obtain a naringenin polyol solution;

[0046] (3) dissolving vitamin E polyethylene glycol succinate in water to obtain an aqueous phase;

[0047] (4) mixing the naringenin polyol solution obtained in the step (2) with the oil phase obtained in the step (1) to obtain a mixed oil phase;

[0048] (5) performing shear emulsification treatment after mixing the mixed oil phase obtained in the step (4) with the water phase obtained in the step (3), to obtain a micron-scale dispersion;

[0049] (6) homogenize the micron-scale dispersion obtained in the step (4) to obtain a naringenin nano composition;

[0050] There is no chronological order limitation between the step (1), step...

Embodiment 1

[0064] Melt 2.0% lauric acid, 4.5% phospholipids, 2.0% caprylic capric triglyceride, and 1.0% polyethylene glycol caprylic capric glyceride in a water bath at 70°C to obtain an oil phase for later use;

[0065] Add 2.0% naringenin to 14% glycerin, and mix evenly in a water bath at 70°C to obtain a naringenin alcohol solution for later use;

[0066] Add 2.0% vitamin E polyethylene glycol succinate to 72.5% purified water, stir and dissolve in a water bath at 70°C to obtain an aqueous phase, and set aside;

[0067] Add the naringenin alcohol solution dropwise to the oil phase at a rate of 3 drops / second, and stir evenly to obtain a mixed oil phase;

[0068] Then add the above-mentioned mixed oil phase to the water phase at a speed of 5 drops / second, and control the stirring rate to 500r / min during the dropping process. After the mixing is completed, high-speed shear emulsification is carried out at a speed of 5000rpm for 6min to obtain micron-sized Dispersions;

[0069] The mi...

Embodiment 2

[0072] Melt 6.5% stearic acid, 2.0% cholesterol, 4.0% diethyl sebacate, and 1.5% caprylic capric acid macrogolglyceride in a water bath at 80°C, and mix them uniformly to obtain an oil phase, which is set aside;

[0073] Add 4.5% naringenin to 45.0% 1,2-propanediol, mix evenly at 80°C to obtain a naringenin alcohol solution, and set aside;

[0074] Add 1.5% vitamin E polyethylene glycol succinate to 35.0% purified water, stir and dissolve in a water bath at 80°C to obtain an aqueous phase, and set aside;

[0075] Add the prepared naringenin alcohol solution dropwise into the oil phase at a rate of 2 drops / second, and stir evenly to obtain a mixed oil phase;

[0076] Add the mixed oil phase to the water phase at a rate of 3 drops / second, and control the stirring rate at 600r / min during the dropping process. After the mixing is completed, high-speed shear emulsification at 7000rpm for 6min to make a micron-sized dispersion ;

[0077]The micron-scale dispersion is subjected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com