Method for preparing butanediamine

A technology of butanediamine and succinonitrile, applied in the field of biochemistry, can solve problems such as inability to synthesize butanediamine, and achieve the effects of great social significance and economic value, high efficiency and yield, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example illustrates the process of producing ammonium succinate by fermentation of Escherichia coli BEW308.

[0033] The culture medium formula described in the present embodiment:

[0034] Plate medium formula is: citric acid 3g / L, Na 2 HPO 4 12H 2 O 4g / L, KH 2 PO 4 8g / L, MgSO 4 ·7H 2 O1g / L, CaCl 2 2H 2 O 10.0mg / L, ZnSO 4 ·7H 2 O 0.5mg / L, CuCl 2 2H 2 O 0.25mg / L, MnSO 4 ·H 2 O2.5mg / L, CoCl 2 ·6H 2 O 1.75mg / L, H 3 BO 3 0.12mg / L, Al 2 (SO4) 3 1.77mg / L, Na 2 MoO 4 2H 2 O0.5mg / L, ferric citrate 16.1mg / L, agar 20g / L, glucose 10g / L, with (NH 4 ) 2 HPO 4 Provide ammonium ions and make NH 4 + The concentration is 0.5mol / L, and the addition amount is 32g / L;

[0035] The formula of the seed medium is: peptone 10g / L, yeast powder 5g / L, NaCl 5g / L;

[0036] The formula of fermentation medium is: citric acid 3g / L, with (NH 4 ) 2 HPO 4 10g / L, Na 2 HPO 4 12H 2 O 4g / L, KH 2 PO 4 8g / L, MgSO 4 ·7H 2 O 1g / L, CaCl 2 2H 2 O 10.0mg / L, ZnSO 4...

Embodiment 2

[0040] This example illustrates the process of using Escherichia coli BEW308 to produce ammonium succinate and obtain a clarified supernatant after fermentation.

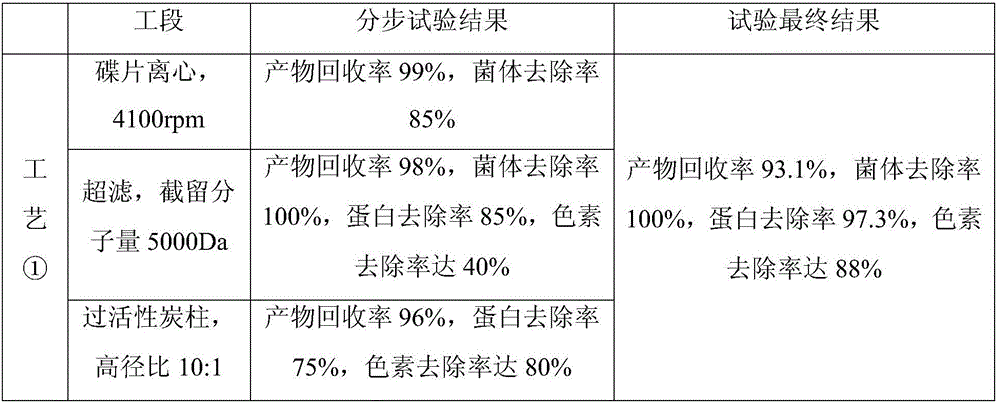

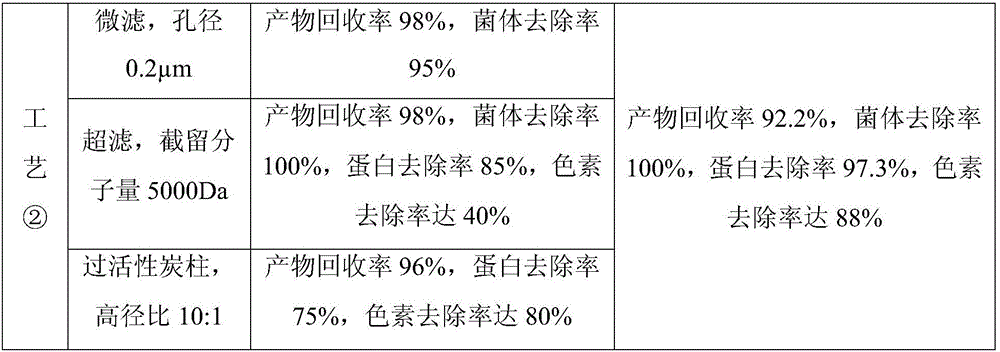

[0041] In order to obtain clarified supernatant in this embodiment, process ① disc centrifugation, ultrafiltration, and activated carbon column were established; process ② microfiltration, ultrafiltration, and activated carbon column two processes were established. The test results are as follows:

[0042]

[0043]

[0044] It can be seen from the test results that both processes can obtain better clarified ammonium succinate aqueous solution, but considering the actual operation process, the process ① has a smaller loss rate of the product, and the operation and operation costs are lower.

Embodiment 3

[0046] This embodiment illustrates the process of clarifying ammonium succinate aqueous solution to prepare butanediamine. In order to obtain butanediamine, the following process is established:

[0047] Using vacuum distillation, control the pressure of the concentration tank to -0.09Mpa, and the temperature at 60°C, and evaporate the supernatant to dryness to obtain crude crystals; transfer the crystals into a 500mL reactor, and control the temperature at 60°C under normal pressure. React at 190°C for 3 hours, the effluent is mainly water and part of ammonia gas, which can be directly connected to the waste water collection tank; connect the vacuum pump to control the vacuum degree of the reactor at 8-9kpa, control the temperature at 180°C for 2 hours, and collect the distillate, namely D Dinitrile; distillate is added to hydrogenation reactor, ethanol is solvent, and addition is 1.1 times (volume ratio) of succinonitrile, and Raney nickel is catalyst, and addition 5%, and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com