Silicon-doped gallium nitride nanoribbon ultraviolet detector and preparation method thereof

A gallium nitride nanometer and silicon-doped technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of long transmission distance of photogenerated carriers, low optical gain, and low optical switching ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

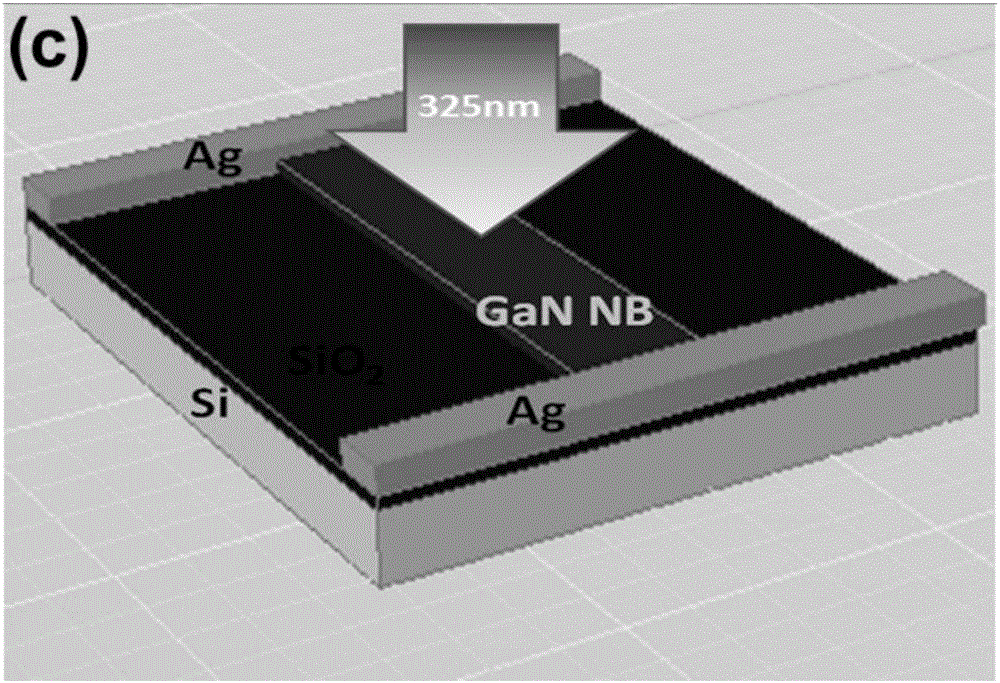

[0035] The invention provides a method for preparing a silicon-doped gallium nitride nanobelt ultraviolet light detector, comprising the following steps:

[0036] (1) Photoetching and potassium hydroxide wet etching patterns on a silicon substrate coated with silicon dioxide as a mask;

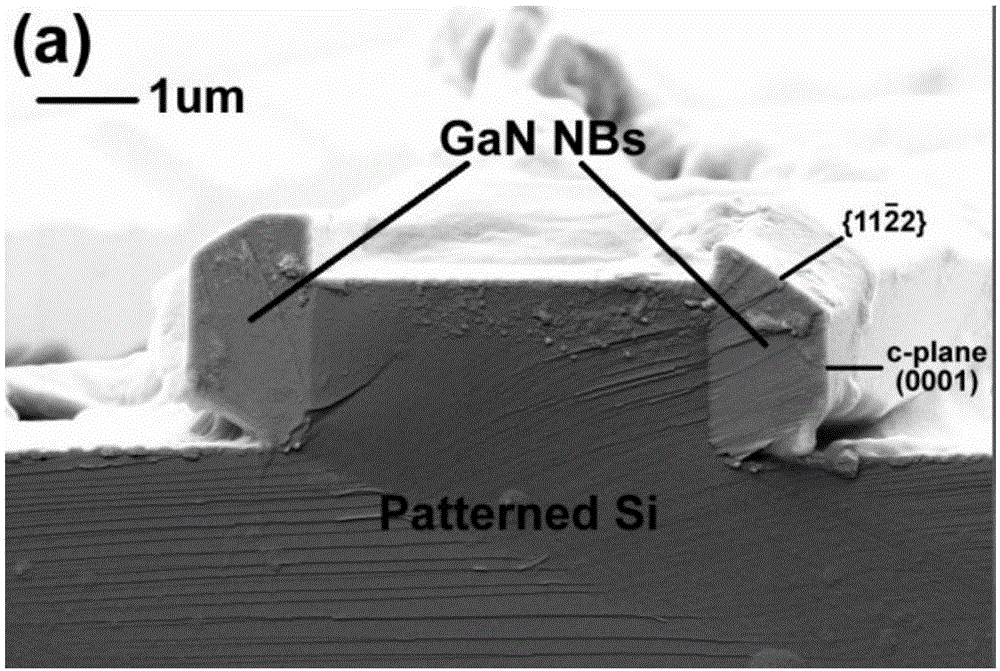

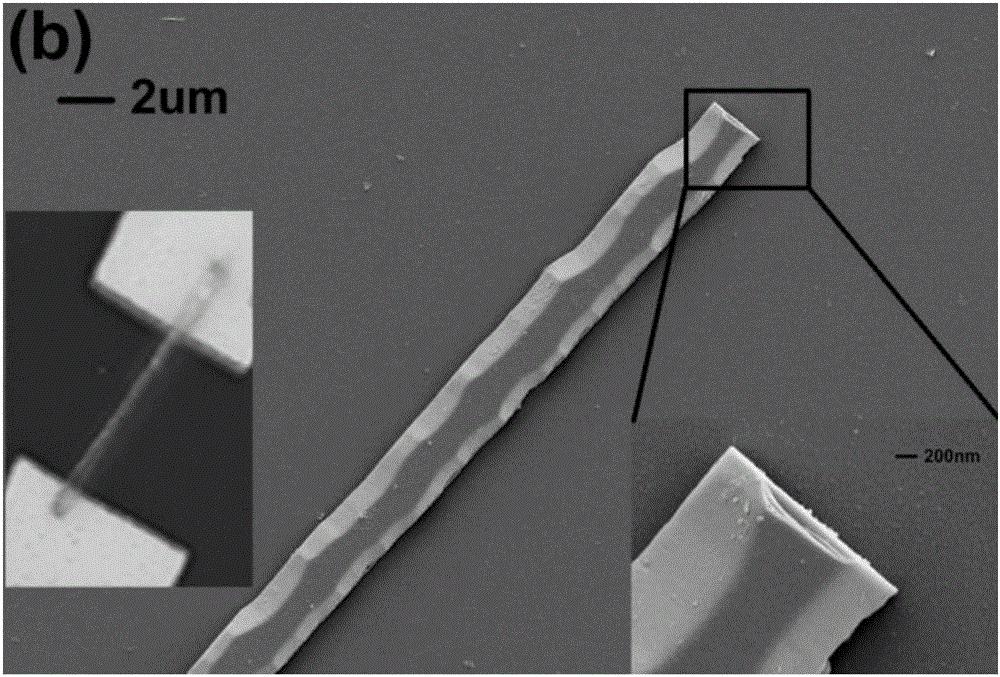

[0037] (2) growing silicon-doped gallium nitride nanobelts on the groove sidewalls of the pattern;

[0038] (3) peeling off the nanobelt, and transferring the peeled nanobelt to a silicon wafer substrate coated with silicon dioxide;

[0039] (4) silver-plated electrodes are plated on the nanobelts of the substrate obtained in the step (3) to obtain a silicon-doped gallium nitride nanobelt ultraviolet light detector.

[0040] In the invention, patterns are photoetched on a silicon substrate plated with silicon dioxide as a mask. In the present invention, the resistivity of the silicon substrate coated with silicon dioxide as a mask is preferably greater than 1000Ω·cm, more preferably greater ...

Embodiment 1

[0056] 1) Photolithography and potassium hydroxide wet etching patterns on a silicon substrate plated with 150nm silicon dioxide as a mask, with a crystal orientation of , a resistivity of 1000Ω·cm, and a thickness of 420μm, to obtain a pattern It is an array of striped grooves with a width of 5.5 μm and a depth of 2 μm, with side walls vertical and parallel to each other. The array of stripe grooves is parallel to the silicon substrate. The crystal orientation, the groove pitch is 4.5μm.

[0057] 2) Using a metal organic compound vapor deposition system to grow silicon-doped gallium nitride nanobelts on the groove sidewall of the patterned silicon substrate obtained in step 1); the silicon doping concentration is 1×10 18 cm- 3 , the nanobelts were grown with a thickness of 0.8 μm.

[0058] 3) Stripping the nanoribbons grown on the silicon substrate in step 2) with a solution having a volume ratio of nitric acid:hydrofluoric acid:water=5:2:1.

[0059] 4) Dissolve the nanob...

Embodiment 2

[0066] 1) On a silicon substrate plated with 100nm silicon dioxide as a mask, the crystal orientation is , the resistivity is 1100Ω·cm, and the thickness is 440μm, the pattern is obtained by photolithography and potassium hydroxide wet etching It is an array of striped grooves with a width of 5.5 μm and a depth of 2 μm, with side walls vertical and parallel to each other. The array of stripe grooves is parallel to the silicon substrate. The crystal orientation, the groove pitch is 4.5μm.

[0067] 2) Using a metal organic compound vapor deposition system to grow silicon-doped gallium nitride nanobelts on the groove sidewall of the patterned silicon substrate obtained in step 1); the silicon doping concentration is 2×10 18 cm- 3 , the nanoribbons were grown with a thickness of 1.2 μm.

[0068] 3) Stripping the nanoribbons grown on the silicon substrate in step 2) with a solution having a volume ratio of nitric acid:hydrofluoric acid:water=5:2:1.

[0069] 4) Dissolve the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com