Anion and cation compound doping spinel lithium manganate and preparation method thereof

A technology of spinel lithium manganese oxide and compound doping, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of unsatisfactory performance of positive electrode materials, complicated process, difficult recycling, etc., and achieve excellent charge-discharge cycle performance and high temperature performance, reasonable and scientific process design, and high initial discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

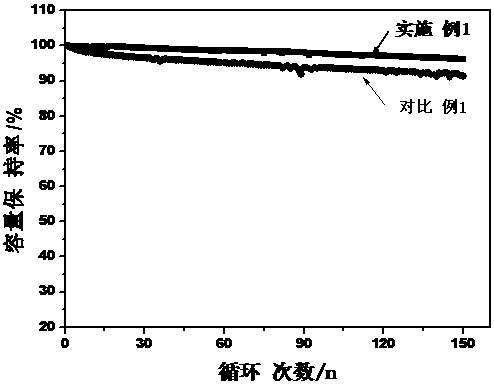

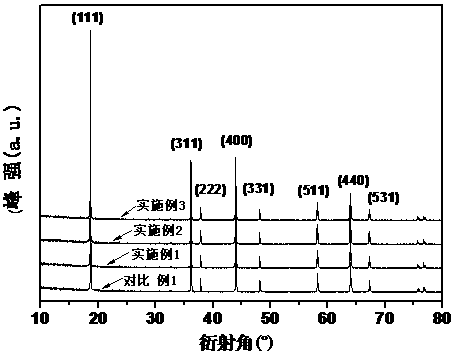

[0035] An anion and cation composite doped spinel lithium manganate of the present invention, and its molecular formula is expressed as LiMn 1.98 (Al) 0.02 O 3.96 (Cl) 0.04 , And the doped cations and anions all enter the spinel lattice of spinel lithium manganate to form a stable single-phase spinel compound.

[0036] The method for preparing anion and cation composite doped spinel lithium manganate in this embodiment includes:

[0037] Take electrodeposited manganese dioxide, lithium carbonate, aluminum oxide, lithium chloride, the molar ratio of these raw materials is MnO 2 :Li 2 CO 3 :Al 2 O 3 :LiCl=1.98:0.5:0.01:0.04, the purity of each substance is above 98%. Fully grind in an agate mortar and mix well to obtain a mixture of doped lithium manganese oxide; then add ethanol solution (mass concentration of 70%) and mix with the mixture to form a slurry, and then place it in a muffle furnace to pre-fire , The temperature rises to the pre-sintering temperature of 450 ℃ within 50 m...

Embodiment 2

[0044] An anion and cation composite doped spinel lithium manganate of the present invention, and its molecular formula is expressed as LiMn 1.94 (Ni) 0.06 O 3.96 (I) 0.04 , And the doped cations and anions all enter the spinel lattice of spinel lithium manganate to form a stable single-phase spinel compound.

[0045] The method for preparing anion and cation composite doped spinel lithium manganate in this embodiment includes:

[0046] Take chemical manganese dioxide, lithium acetate, nickel oxide, and lithium iodide. The molar ratio of these raw materials is MnO 2 :CH 3 COOLi:NiO:LiI=1.94:1.0:0.06:0.04, the purity of each substance is above 98%. Fully grind in an agate mortar and mix well to obtain a mixture of doped lithium manganese oxide; then add ethanol solution (mass concentration of 70%) and mix with the mixture to form a slurry, and then place it in a muffle furnace to pre-fire , The temperature was raised to the pre-sintering temperature of 500 ℃ within 50 minutes, and t...

Embodiment 3

[0050] An anion and cation composite doped spinel lithium manganate of the present invention, and its molecular formula is expressed as LiMn 1.94 (Cr) 0.06 O 3.98 (F) 0.02 , And the doped cations and anions all enter the spinel lattice of spinel lithium manganate to form a stable single-phase spinel compound.

[0051] The method for preparing anion and cation composite doped spinel lithium manganate in this embodiment includes:

[0052] Take electrodeposited manganese dioxide and manganese trioxide, lithium hydroxide, chromium oxide, lithium fluoride, the molar ratio of these raw materials is (MnO 2 +Mn 2 O 3 ):LiOH:Cr 2 O 3 :LiF=1.94 (manganese element in manganese source): 1.0:0.03:0.02, the purity of each substance is above 98%. Fully grind in an agate mortar and mix well to obtain a mixture of doped lithium manganese oxide; then add ethanol solution (mass concentration of 70%) and mix with the mixture to form a slurry, and then place it in a muffle furnace to pre-fire , The tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com