Tear-resistant nano-modified rubber for controlling noise and preparation method thereof

A nano-modified and tear-resistant technology, applied in the field of air purification, can solve the problems of environmental pollution and difficult diffusion of pollutants, and achieve the effects of high adhesion, enhanced mechanical properties, and good thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

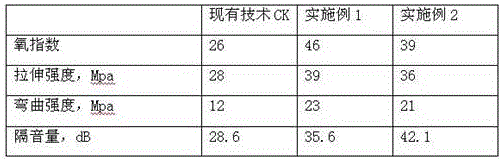

Embodiment 1

[0019] A tear-resistant nano-modified rubber for preventing and controlling noise, which consists of raw materials: 5 parts of dimethyl vinyl ethoxysilane, 4 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 8 parts of allophane powder 15 parts of maleic anhydride grafted polyvinyl chloride, 50 parts of polystyrene, 20 parts of polyisocyanurate, 5 parts of glass pumice, 4 parts of porous manganese slag, 6 parts of hollow microspheres, pitch-based carbon fiber powder 6 parts, 5 parts of non-halogenated organic phosphinates, 8 parts of hexamethylenetetramine, 2 parts of trimethylpentyltriethoxysilane, 0.3 parts by weight of conductive mica powder, 0.2 parts by weight of nano-conductive graphite powder, 0.8 parts by weight of trimer of polyisocyanate, 1 part by weight of polytetrafluoroethylene fiber, 50 parts by weight of activated carbon, 12 parts by weight of montmorillonite, 5 parts by weight of nano-titanium dioxide, 3 parts by weight of silicon dioxide, γ-aminopro...

Embodiment 2

[0028] Embodiment 2 A kind of tear-resistant nano-modified rubber for preventing and controlling noise and its preparation method

[0029]A tear-resistant nano-modified rubber for preventing and controlling noise, which includes the following raw materials: 8 parts of dimethyl vinyl ethoxysilane, 6 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 10 parts of allophane powder 20 parts of maleic anhydride grafted polyvinyl chloride, 70 parts of polystyrene, 30 parts of polyisocyanurate, 8 parts of glass pumice, 6 parts of porous manganese slag, 8 parts of hollow microbeads, pitch-based carbon fiber powder 8 parts, 7 parts of non-halogenated organic phosphinates, 10 parts of hexamethylenetetramine, 4 parts of trimethylpentyltriethoxysilane, 0.5 parts by weight of conductive mica powder, 0.4 parts by weight of nano-conductive graphite powder, 1 part by weight of trimer of polyisocyanate, 2 parts by weight of polytetrafluoroethylene fiber, 70 parts by weight of activate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com